Description:

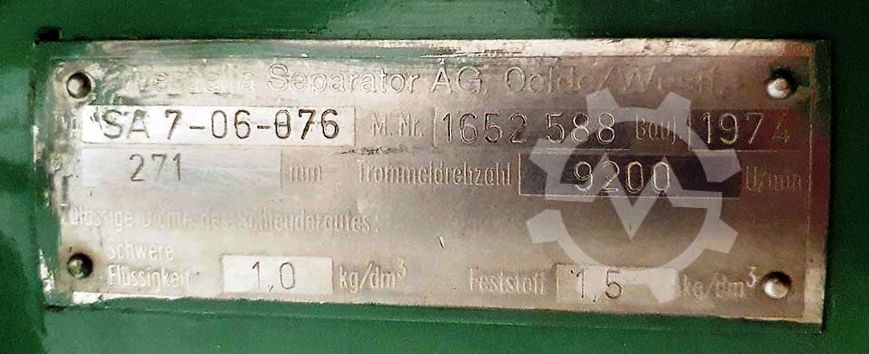

Max bowl speed 9200 RPM, rated @ 20 GPM. 4 KW motor 380/3/50/1400 RPM with piping, water harness, tools and PLC control panel, unitized on SS skid, plus spare parts. 1974 vintage. Excellent condition. Located in Europe.

The (2) Westfalia SA 7-06-076 clarifier centrifuges, 316SS, are engineered for high-efficiency separation processes, making them an essential asset for industries requiring precise liquid-solid separation. With a maximum bowl speed of 9200 RPM, these centrifuges can achieve a flow rate of 20 GPM, allowing for rapid processing of large volumes of material. The robust 4 KW motor, operating at 380/3/50/1400 RPM, ensures reliable performance under demanding conditions. Each unit is equipped with essential components, including piping, a water harness, tools, and a PLC control panel, all unitized on a durable stainless steel skid. This configuration not only enhances the operational efficiency but also simplifies installation and maintenance, making it an ideal choice for facilities looking to optimize their processing capabilities.

Manufactured in 1974, these centrifuges have been meticulously maintained and are in excellent condition, demonstrating the longevity and reliability of Westfalia's engineering. The use of 316 stainless steel in their construction provides superior corrosion resistance, making them suitable for a variety of applications, including food processing, pharmaceuticals, and chemical industries. The inclusion of spare parts further ensures that operators can maintain peak performance with minimal downtime. Given their vintage, these centrifuges represent a blend of classic design and modern functionality, making them a valuable addition to any industrial operation seeking to enhance its separation processes.

Key Features:

High-Speed Performance, Durable Construction, Comprehensive Control System, Efficient Liquid-Solid Separation, Easy Installation and Maintenance