Description:

Max bowl speed 950 RPM, 1250 x 800mm basket, 606 kg max load, 3.2 sqM filter area. Pneumatic top discharge, gastight design, 30 KW XP motor 400/3/50 with VFD, pneumatic peeler, feed and wash pipes, rotating spray head, manhole cover with large light and sight glasses, filtrate discharge pipe, basket rinser, unitized on an inertia base with Visco-spring dampeners, connections for inert gas and lubrication and control panel. 1995 vintage. Excellent condition. Located in Europe.

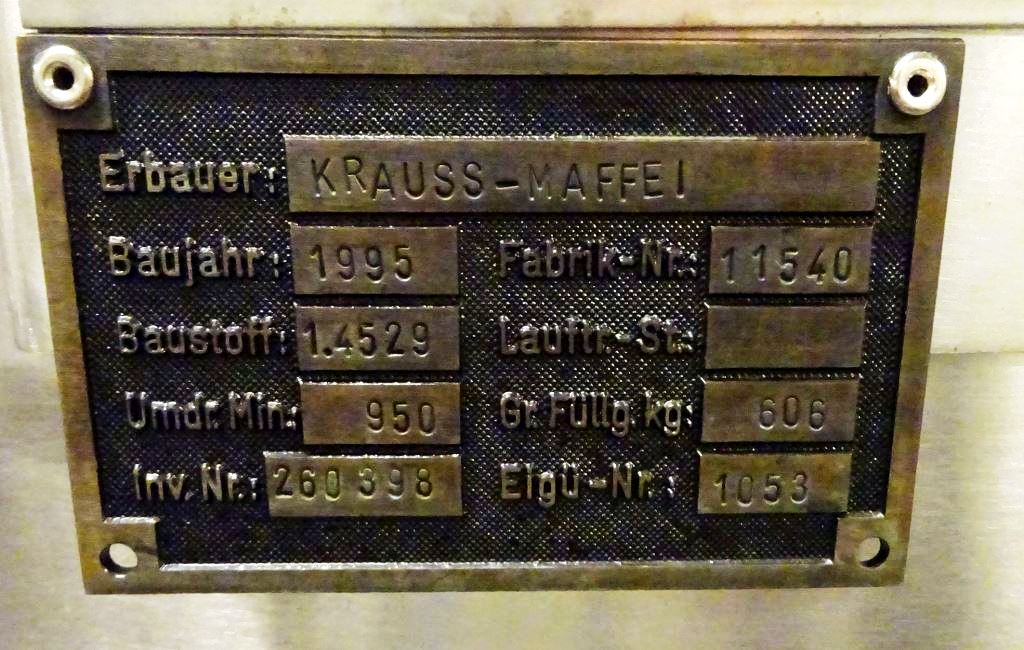

The (3) Krauss-Maffei VZO-125/3.2C perforate basket centrifuges, Incoloy 926, are engineered for high-performance separation processes, making them an invaluable asset for industries requiring efficient solid-liquid separation. With a maximum bowl speed of 950 RPM, these centrifuges are capable of handling a substantial load of up to 606 kg, ensuring optimal throughput for various applications. The generously sized 1250 x 800mm basket, combined with a filter area of 3.2 square meters, allows for effective filtration, making these units suitable for a wide range of materials, including those that are challenging to process. The pneumatic top discharge feature enhances operational efficiency by facilitating quick and clean removal of solids, while the gastight design ensures that the process remains contained, minimizing the risk of contamination and enhancing safety in the working environment.

Equipped with a robust 30 KW XP motor operating at 400/3/50 with a variable frequency drive (VFD), these centrifuges offer precise control over speed and torque, allowing for tailored processing conditions to meet specific requirements. The inclusion of a pneumatic peeler, feed and wash pipes, and a rotating spray head further streamlines the cleaning and maintenance processes, reducing downtime and enhancing productivity. Additionally, the manhole cover features large light and sight glasses, providing operators with clear visibility of the process, which is critical for monitoring and ensuring optimal performance. The basket rinser and the unitized design on an inertia base with Visco-spring dampeners contribute to the overall stability and reliability of the equipment during operation, making it an excellent choice for continuous processing environments. With connections for inert gas and lubrication, as well as an integrated control panel, these centrifuges are designed for ease of use and maintenance, ensuring they remain in excellent condition for years to come.

Key Features:

High-Speed Performance, Durable Construction, Easy Maintenance, Pneumatic Discharge System, Versatile Applications