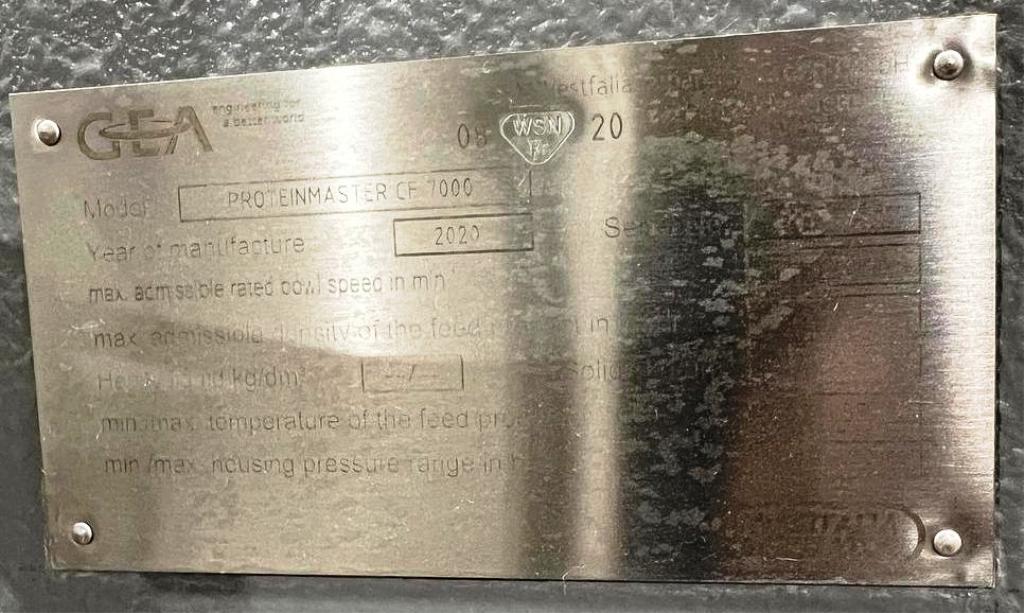

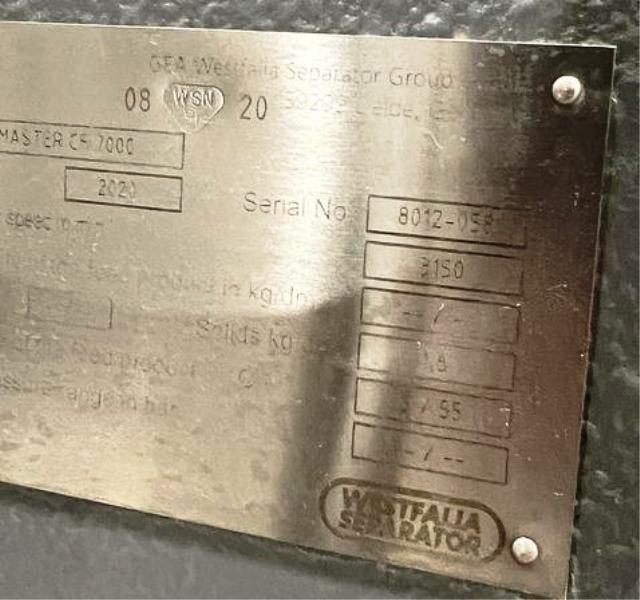

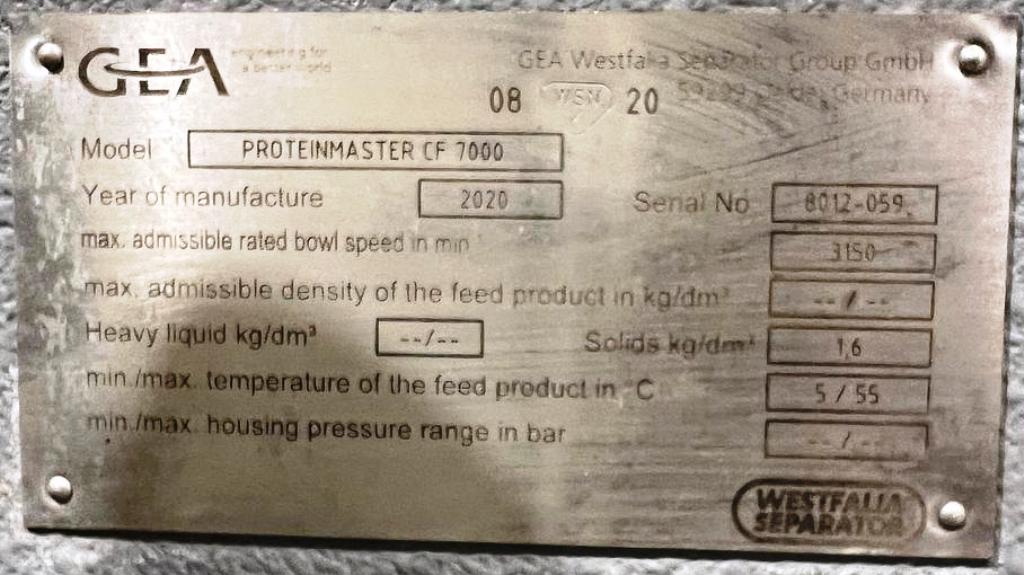

Description:

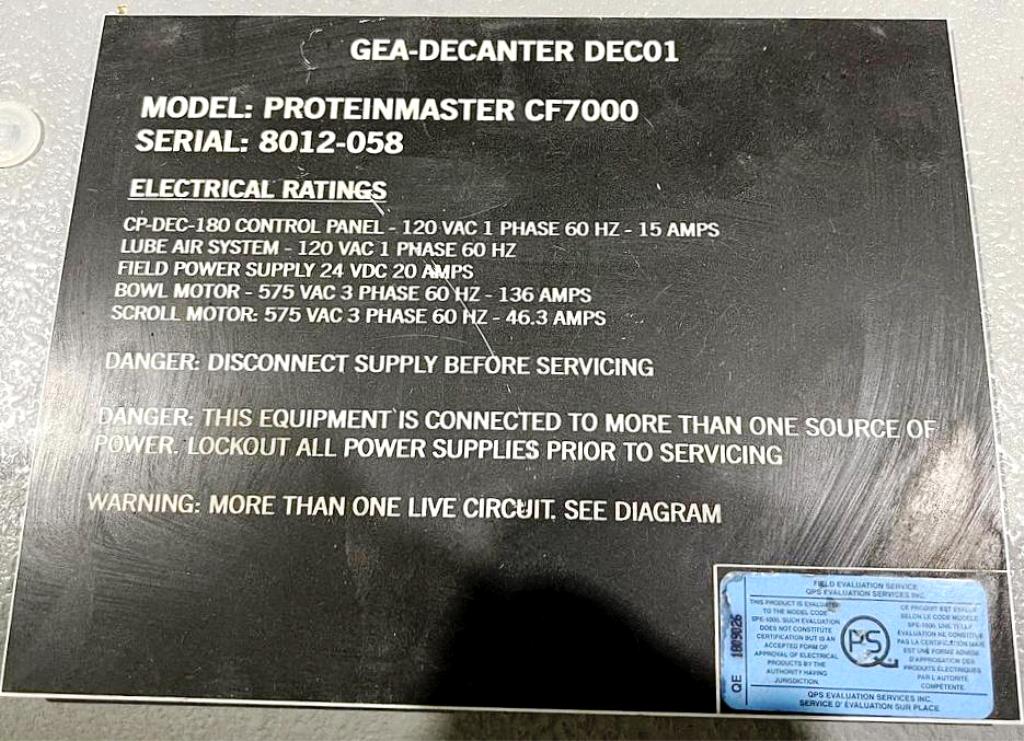

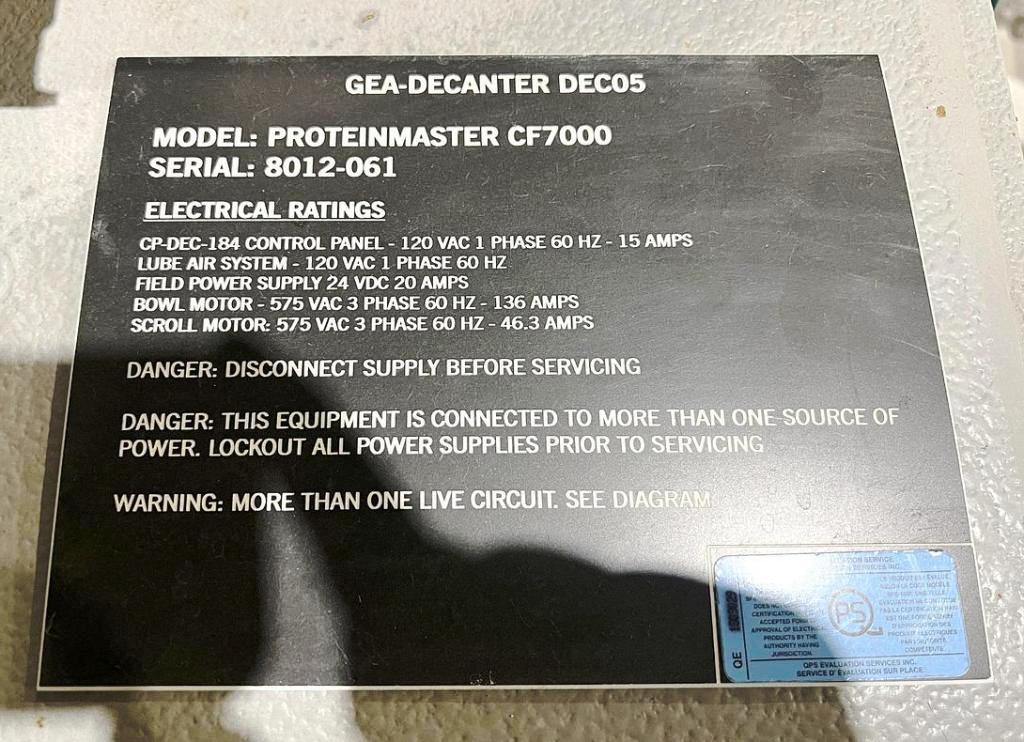

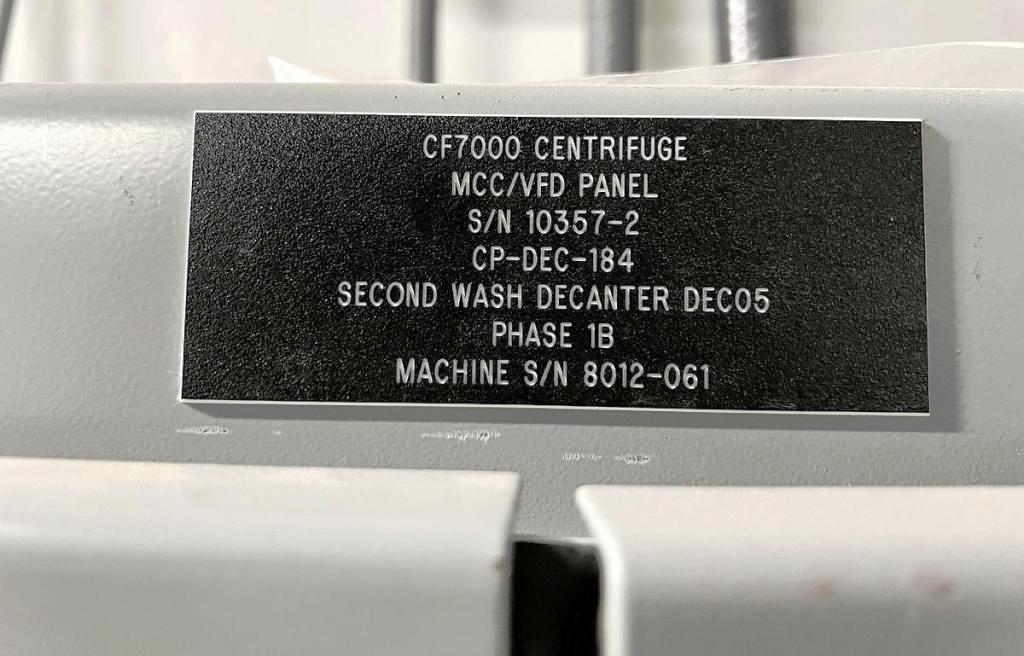

Max bowl speed 3150 RPM, 3550 x G, 640 x 2560mm (25.2 x 100.8") bowl ID. 10" single lead polished conveyor, 150 HP motor 575/3/60/1780 RPM, cyclo gearbox, 45 HP backdrive, feed tube, guards, lube system, vibration switch/isolators, chutes, PLC control panel with 2 VFDs and start/stop panel. Prior use: Plant protein. 2020 vintage. Excellent condition. Located in Canada.

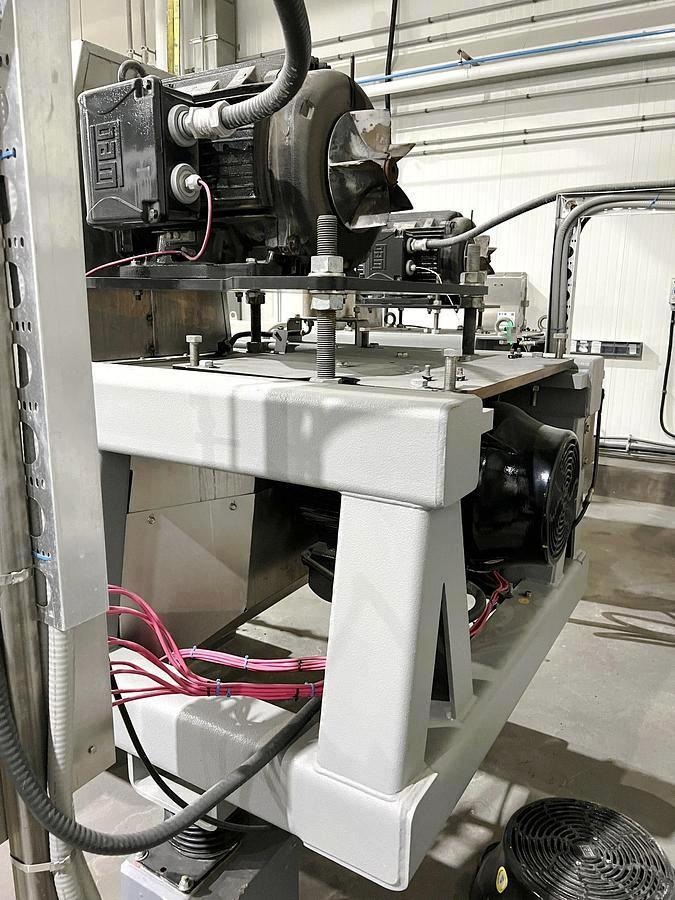

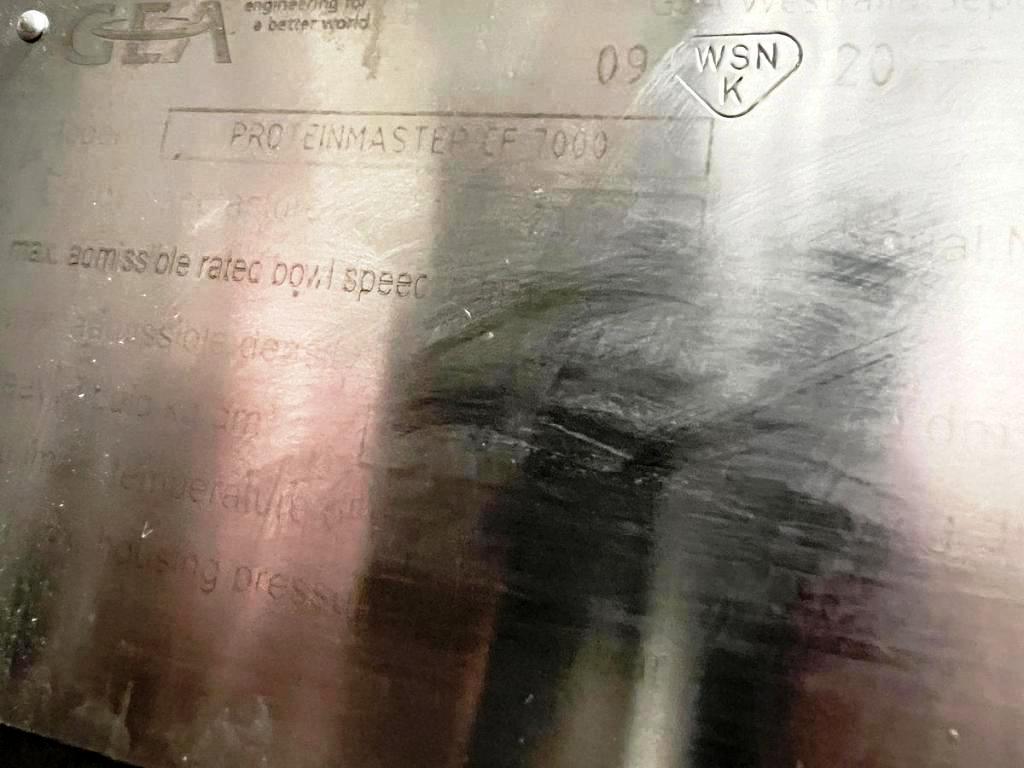

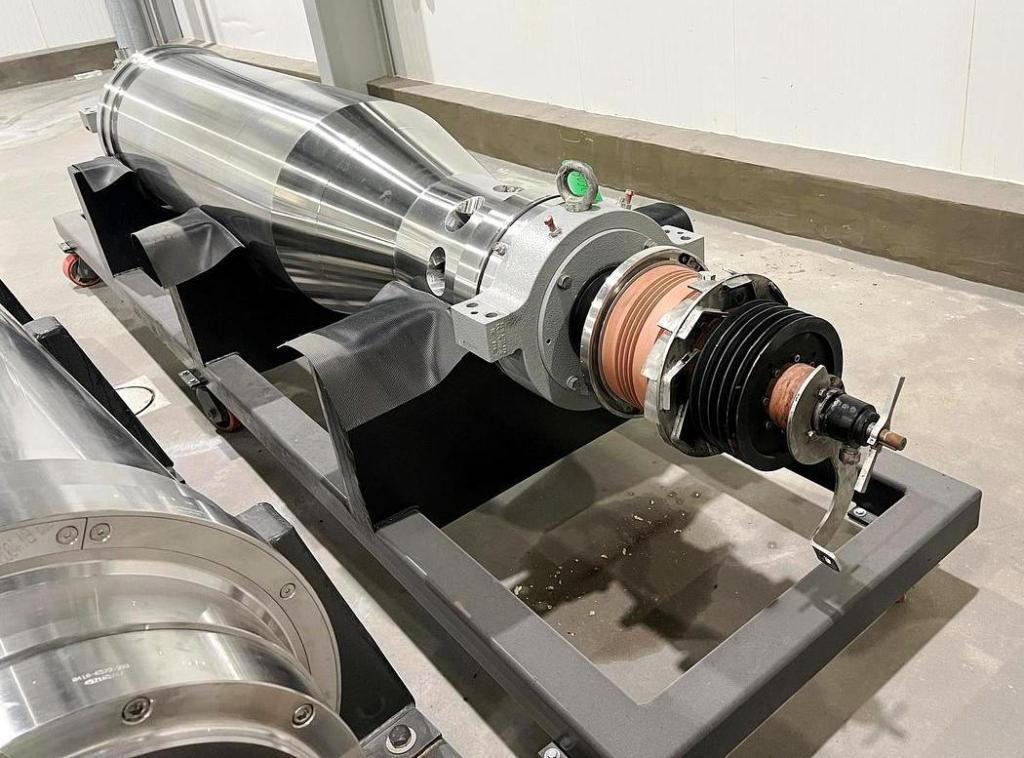

The (4) GEA Westfalia ProteinMaster CF 7000 sanitary tricanter centrifuges, 316SS. are engineered to deliver exceptional performance in the separation of plant proteins, making them an invaluable asset for any industrial processing facility. With a maximum bowl speed of 3150 RPM and a centrifugal force of 3550 x G, these centrifuges are designed to efficiently separate solids from liquids, ensuring high yield and purity of the extracted proteins. The bowl dimensions of 640 x 2560mm (25.2 x 100.8") provide ample capacity for large-scale operations, while the 10" single lead polished conveyor enhances the transport of separated solids, minimizing any potential for cross-contamination and ensuring sanitary processing standards are met.

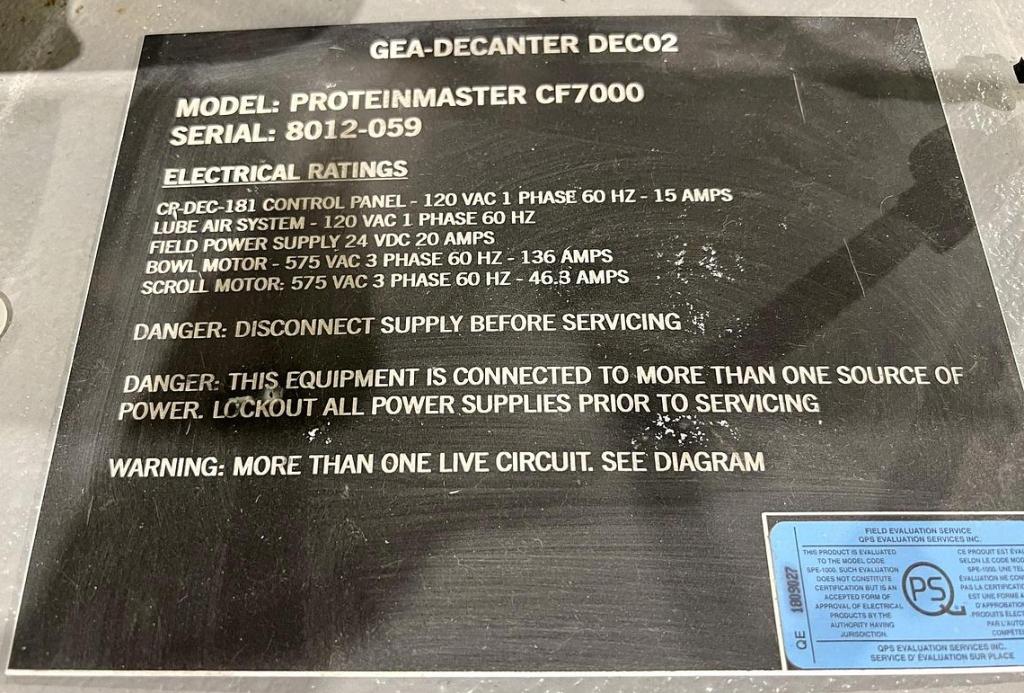

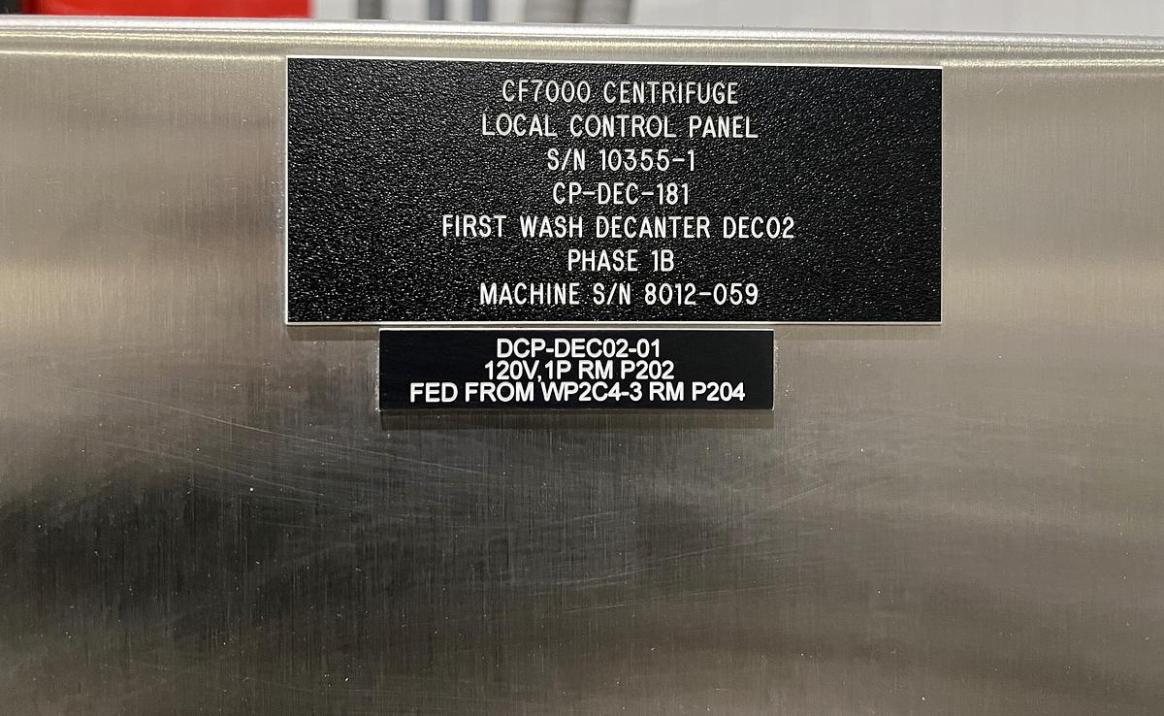

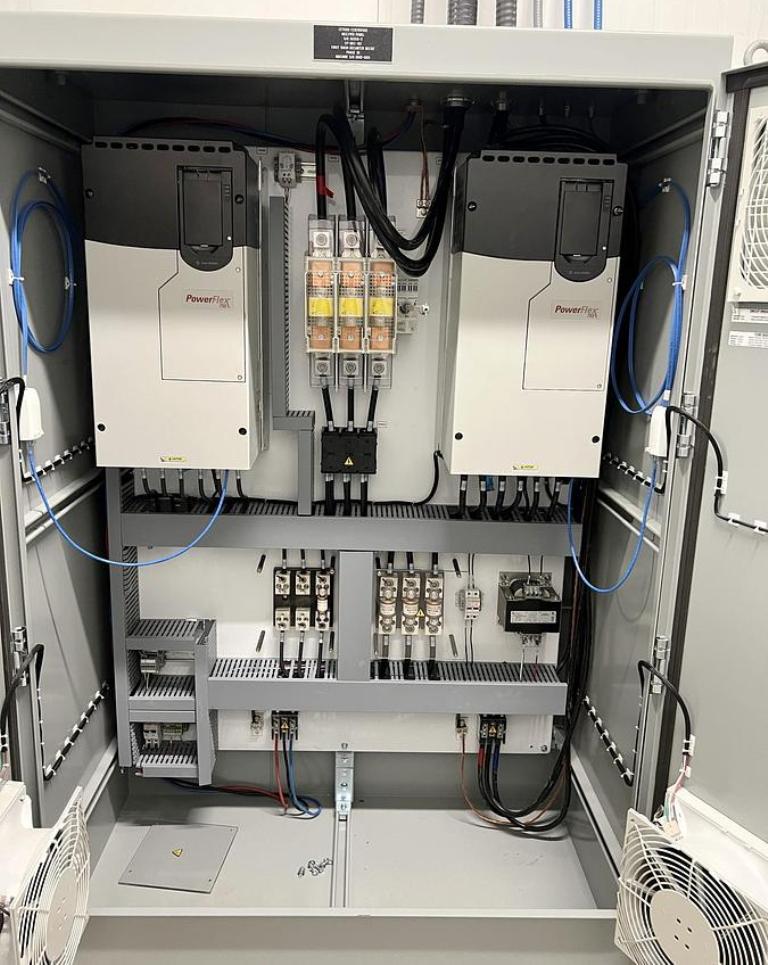

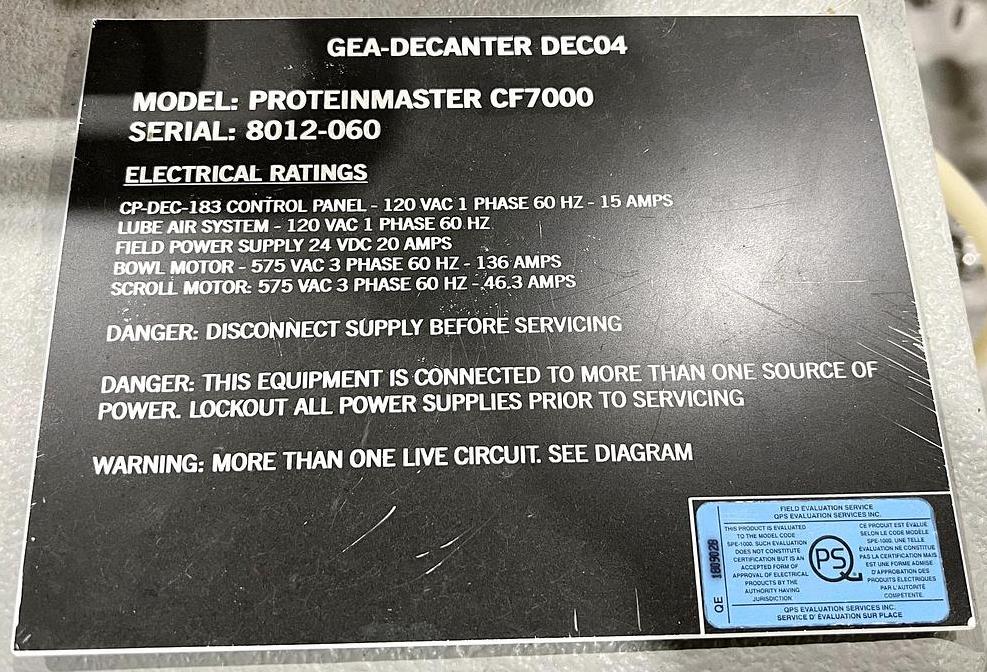

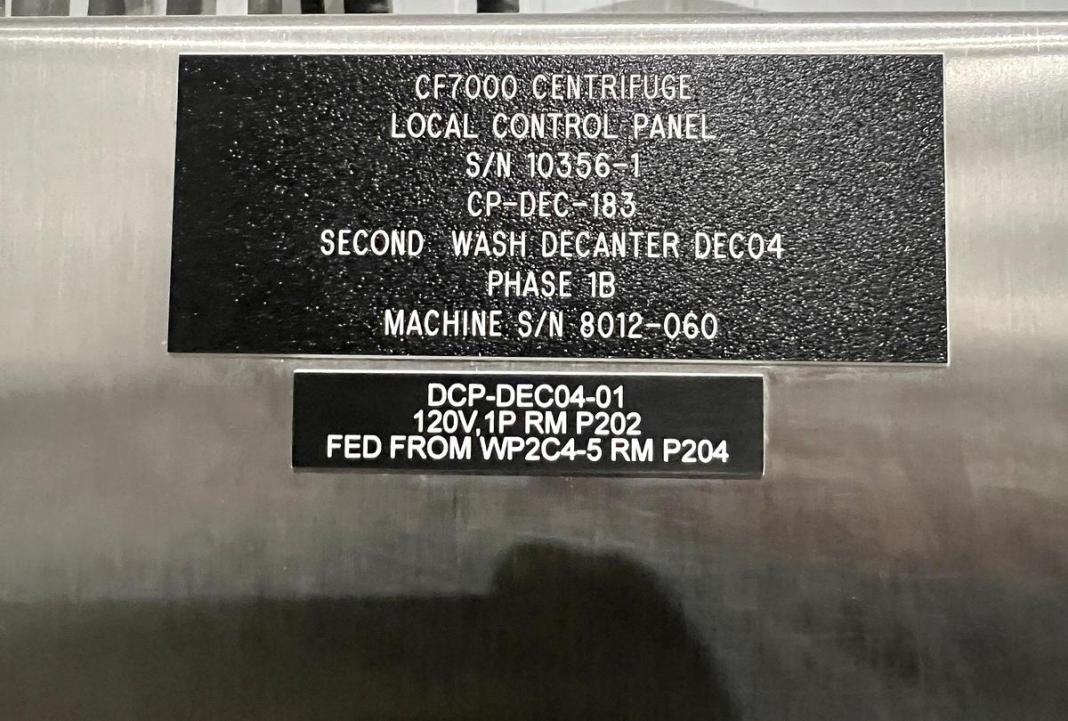

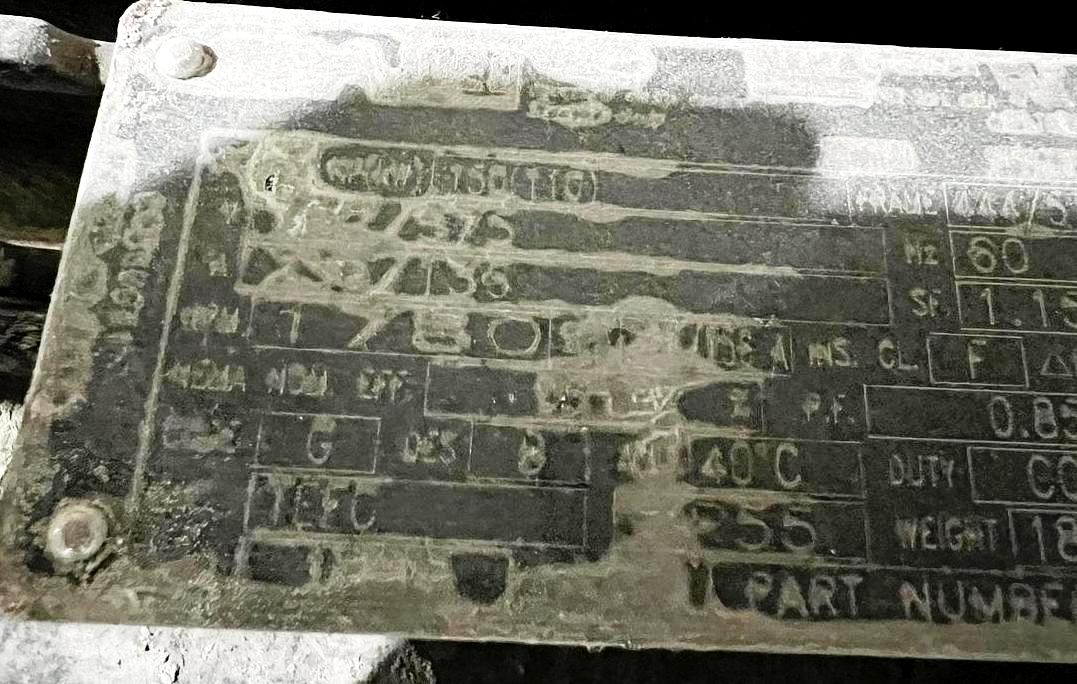

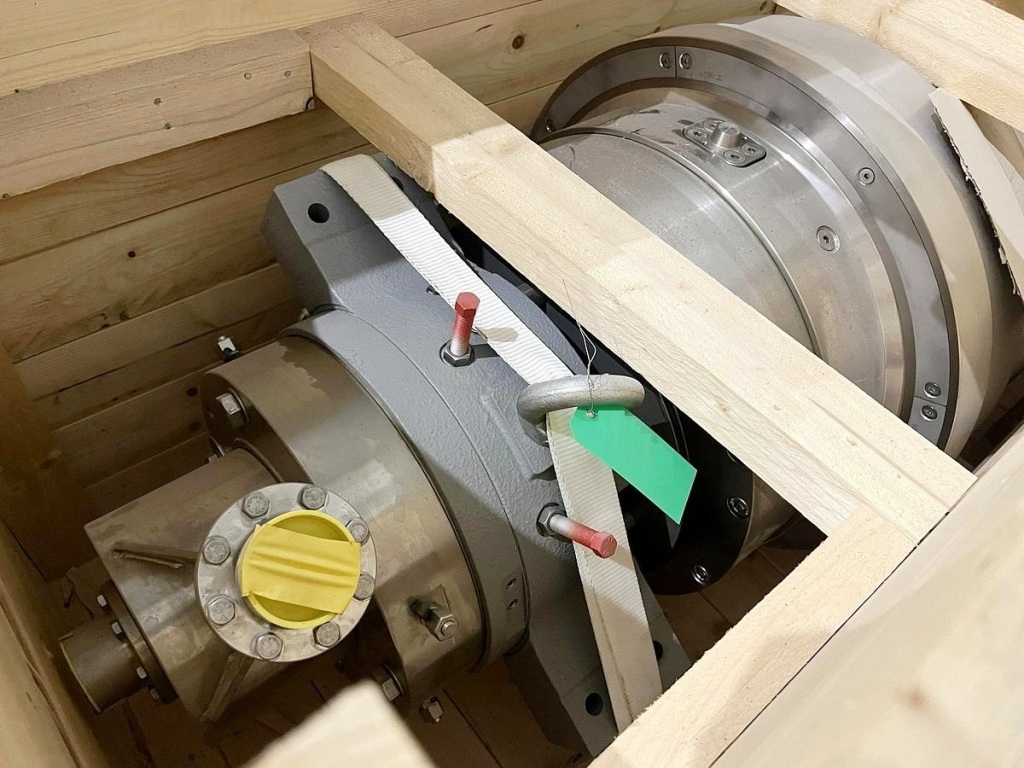

Equipped with a robust 150 HP motor operating at 575/3/60/1780 RPM, the GEA Westfalia ProteinMaster CF 7000 units utilize a cyclo gearbox that optimizes torque and efficiency, making them suitable for continuous operation in demanding environments. The inclusion of a 45 HP backdrive ensures that the system remains operational even under varying load conditions, providing reliability and consistency in performance. Additionally, the centrifuges come with essential features such as a feed tube, guards, a lubrication system, vibration switch/isolators, and chutes, all of which contribute to the overall safety and efficiency of the equipment. The PLC control panel, equipped with two variable frequency drives (VFDs) and a start/stop panel, allows for precise control over the centrifuge operations, enabling operators to adjust settings according to specific processing requirements.

Having been manufactured in 2020, these centrifuges are in excellent condition, reflecting their minimal prior use in plant protein applications. Their stainless steel construction (316SS) not only ensures durability and resistance to corrosion but also facilitates easy cleaning and maintenance, adhering to the stringent hygiene standards required in food and beverage processing. Located in Canada, these centrifuges are ready for immediate deployment, offering an efficient solution for businesses looking to enhance their protein separation processes.

Key Features:

High-Speed Performance, Durable Construction, Advanced Control System, Efficient Separation, Safety Features