Description:

The line consists of a Bertsch thermizer/pasteurizer, 2 cheese vats (8500 and 10,500 LPH), Alpma mold filling, whey treatment, whey sieve and Westfalia MSA 60-01-076 separator with 17 KW motor, tools and Siemens S7 controls, starter production tank, CIP set, molds and mold turning device with SS trolleys, brine baths, ripening racks, waxing and cleaning equipment. 1985 vintage. Excellent condition. Located in Europe.

The 8500 LPH soft & semi-hard cheese production line is a comprehensive solution designed for efficient cheese manufacturing, suitable for both small-scale and larger operations. This line is equipped with a Bertsch thermizer/pasteurizer that ensures precise temperature control, essential for maintaining the quality and safety of dairy products. The two cheese vats, capable of processing 8500 and 10,500 liters per hour, allow for flexibility in production volumes, accommodating varying batch sizes and types of cheese. The integration of Alpma mold filling technology enhances the efficiency of cheese molding, while the whey treatment and whey sieve systems ensure optimal recovery and processing of whey, a valuable by-product in cheese production. The Westfalia MSA 60-01-076 separator, powered by a robust 17 KW motor, plays a crucial role in separating cream from milk, further enhancing the quality of the final product.

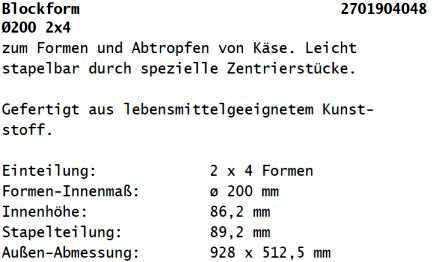

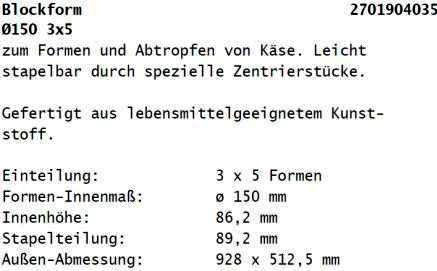

This production line not only emphasizes efficiency but also prioritizes ease of operation and maintenance. The inclusion of Siemens S7 controls allows for seamless automation and monitoring of the entire production process, ensuring consistent quality and reducing the potential for human error. The starter production tank, along with the CIP (Clean-In-Place) set, simplifies the cleaning process, ensuring that hygiene standards are met without significant downtime. Additionally, the line comes with essential accessories such as molds, a mold turning device with stainless steel trolleys, brine baths for curing, ripening racks for aging cheese, and waxing and cleaning equipment, all designed to streamline the production workflow. With its vintage dating back to 1985, this line has been meticulously maintained and is in excellent condition, making it a valuable investment for any cheese production facility looking to enhance its operational capabilities.

Located in Europe, this 8500 LPH soft & semi-hard cheese production line presents an opportunity for buyers to acquire a high-quality, well-maintained system that can significantly boost production efficiency and product quality. Whether you are looking to expand your existing operations or start a new venture in cheese production, this line offers the versatility and reliability needed to meet the demands of the market.

Key Features:

High-Speed Production Capacity, Advanced Automation Controls, Efficient Whey Processing, Comprehensive Cleaning Solutions, Versatile Cheese Molding Options