Description:

Max bowl speed 3250 RPM, 2657 Gs, 450 x 1910mm bowl = 17.7 x 75.2", 10 degree beach. 6" single lead STC-tiled conveyor, 75 HP motor 230/460/3/60/1750 RPM, 159:1 3.5 kNm gearbox, 15 HP ECB backdrive, guards, polymer feed tube, lube system, vibration switch/isolators and PLC control panels. Unitized on a stand with chutes and cake take-away conveyor. 1999 vintage. Reconditioned. Includes (2) Seepex pumps, feed pump, water pump, built-in muffin monster on the feed line, dam plates and programming software. Mounted in a 28' box truck.

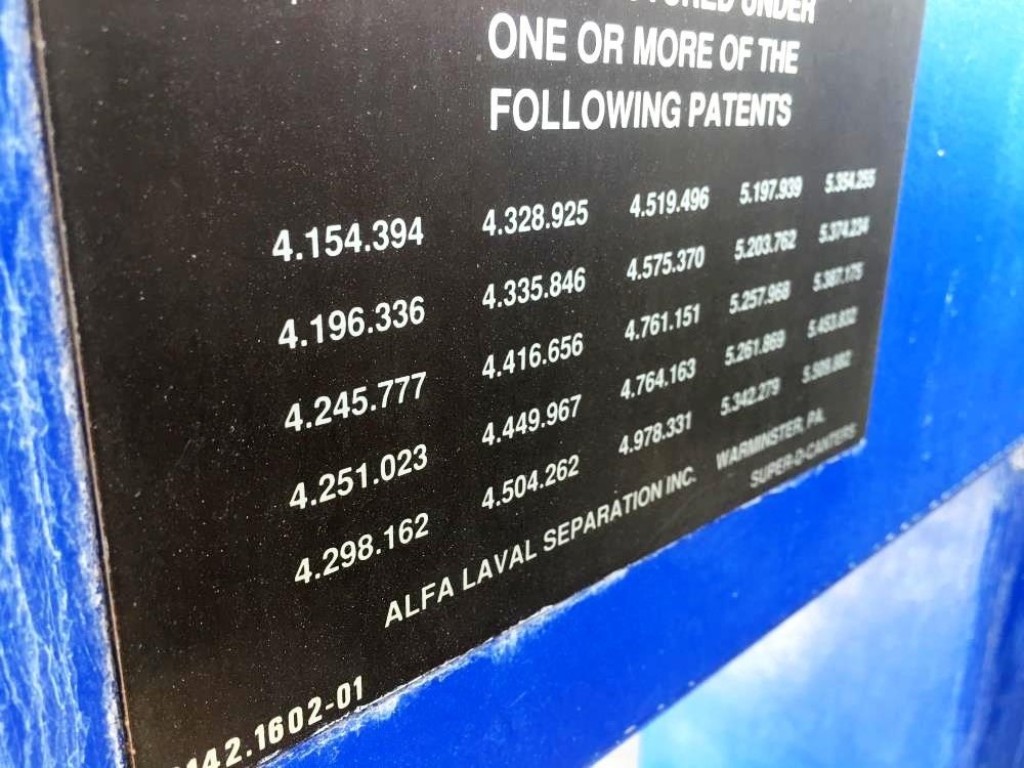

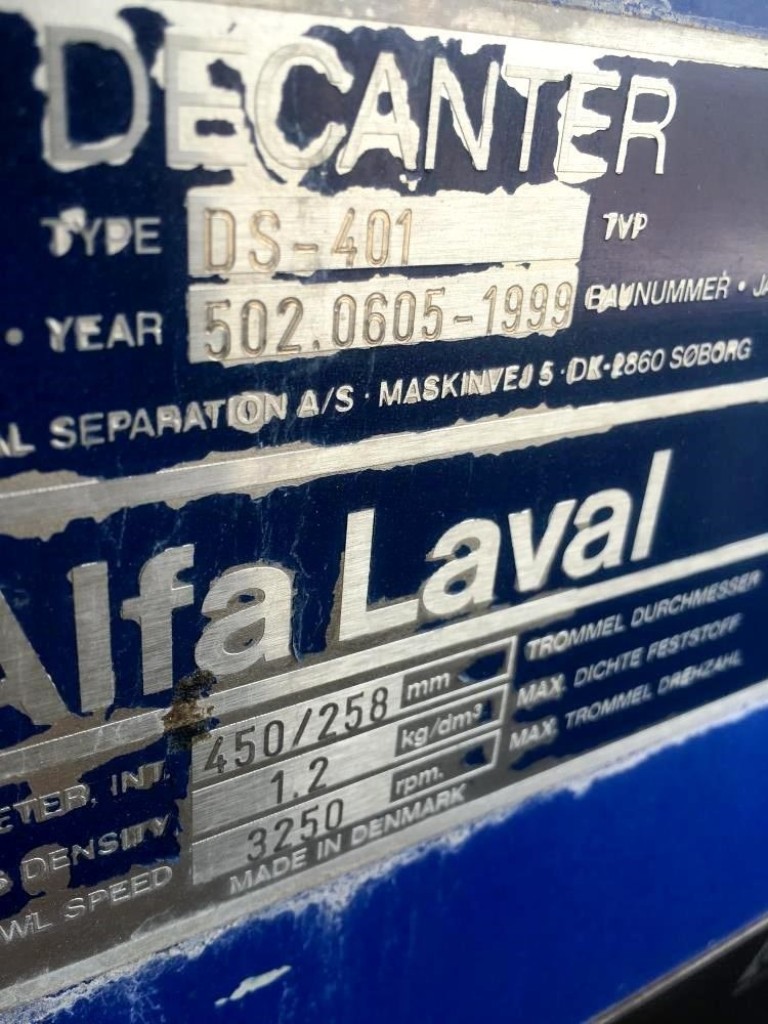

The Alfa-Laval DS-401 trailer-mounted decanter centrifuge, 316SS, is engineered for high-performance separation processes, making it an ideal choice for various industrial applications. With a maximum bowl speed of 3250 RPM and generating up to 2657 Gs, this centrifuge is capable of efficiently separating solids from liquids in a wide range of materials. The 450 x 1910mm bowl, which measures 17.7 x 75.2 inches, features a 10-degree beach angle that optimizes the separation process, ensuring that the solids are effectively discharged while minimizing liquid carryover. The 6-inch single lead STC-tiled conveyor is designed to handle the solids output with precision, further enhancing the overall efficiency of the operation. Powered by a robust 75 HP motor, this unit operates on a versatile 230/460/3/60/1750 RPM configuration, making it adaptable to various power supply conditions.

In addition to its powerful motor, the Alfa-Laval DS-401 is equipped with a 159:1 3.5 kNm gearbox and a 15 HP ECB backdrive, ensuring smooth operation and reliable performance under demanding conditions. Safety features such as guards, a vibration switch, and isolators are included to protect both the equipment and personnel during operation. The advanced PLC control panels provide operators with user-friendly access to monitor and adjust settings, enhancing operational control and efficiency. This unit is mounted on a sturdy stand with integrated chutes and a cake take-away conveyor, streamlining the entire process from feed to discharge. The 1999 vintage centrifuge has been meticulously reconditioned to meet high standards of performance and reliability, ensuring that it is ready for immediate use in your operations.

Included with the Alfa-Laval DS-401 are two Seepex pumps—a feed pump and a water pump—along with a built-in muffin monster on the feed line, dam plates, and programming software. These additional components enhance the functionality of the centrifuge, allowing for seamless integration into existing systems. The entire setup is conveniently housed within a 28-foot box truck, providing mobility and ease of transport to various job sites. This trailer-mounted solution is designed for industries that require efficient solid-liquid separation, such as wastewater treatment, food processing, and chemical manufacturing, making it a versatile addition to any industrial fleet.

Key Features:

High-Speed Performance, Durable Construction, Easy Maintenance, Advanced Control Systems, Mobility and Transportability