Description:

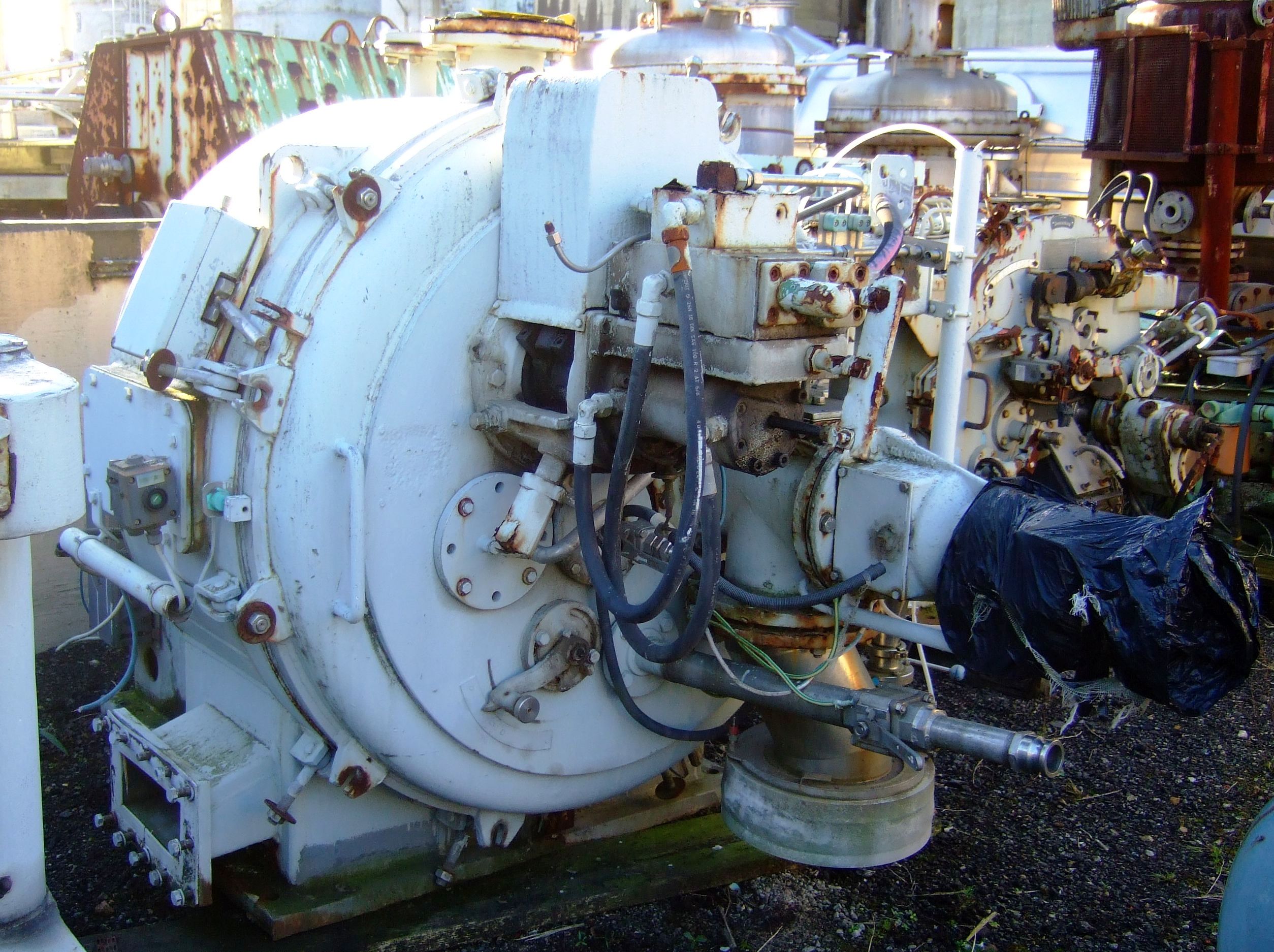

Max bowl speed 1400 RPM, 1260 x G, 1.81 sqm filtering surface, 222 L cake volume, 280 kg max load, 0.5 bar design pressure. 30 KW XP motor 380/3/50 with VFD, rotary siphon, front skimming pipe, automatic CIP spray nozzle, hydraulic plow with pneumatic heel cake removal system, hydraulic power pack, solids discharge chute, vibration dampeners, door lock switch and 2 control panels. Excellent condition. Located in Europe.

The Comi-Condor HX/GMP 1150/500 ATEX peeler centrifuge, 316L SS, is engineered to meet the rigorous demands of industrial applications while ensuring safety and efficiency. With a maximum bowl speed of 1400 RPM and a centrifugal force of 1260 x G, this centrifuge is capable of delivering exceptional separation performance. The 1.81 square meters of filtering surface allows for optimal filtration, making it suitable for a variety of processes, including the separation of solids from liquids in chemical, pharmaceutical, and food processing industries. The 222-liter cake volume and 280 kg maximum load capacity ensure that it can handle substantial batches, enhancing productivity in high-demand environments. Designed with a 0.5 bar design pressure, this equipment is built to withstand the pressures of continuous operation while maintaining safety standards.

Equipped with a robust 30 KW XP motor operating at 380/3/50 with a variable frequency drive (VFD), the Comi-Condor HX/GMP 1150/500 ATEX peeler centrifuge offers precise control over the speed and torque, allowing for tailored processing conditions. The inclusion of a rotary siphon and front skimming pipe enhances the efficiency of the discharge process, while the automatic CIP spray nozzle simplifies maintenance and ensures cleanliness between batches. The hydraulic plow and pneumatic heel cake removal system work in tandem to facilitate the efficient removal of solids, minimizing downtime and maximizing throughput. Additionally, the hydraulic power pack and solids discharge chute are designed for seamless operation, while vibration dampeners contribute to the overall stability and longevity of the machine. With dual control panels and a door lock switch, operators can easily manage and monitor the centrifuge, ensuring a safe working environment.

This centrifuge is in excellent condition and is located in Europe, making it a valuable addition for businesses looking to enhance their processing capabilities. Its construction from 316L stainless steel ensures durability and resistance to corrosion, making it suitable for handling aggressive chemicals and maintaining hygiene standards in sensitive applications. The Comi-Condor HX/GMP 1150/500 ATEX peeler centrifuge is not just a piece of equipment; it is a comprehensive solution designed to optimize your operational efficiency while adhering to the highest safety and quality standards.

Key Features:

High-Speed Performance, Durable Construction, Efficient Solids Discharge, User-Friendly Control Panels, Automatic Cleaning System