Description:

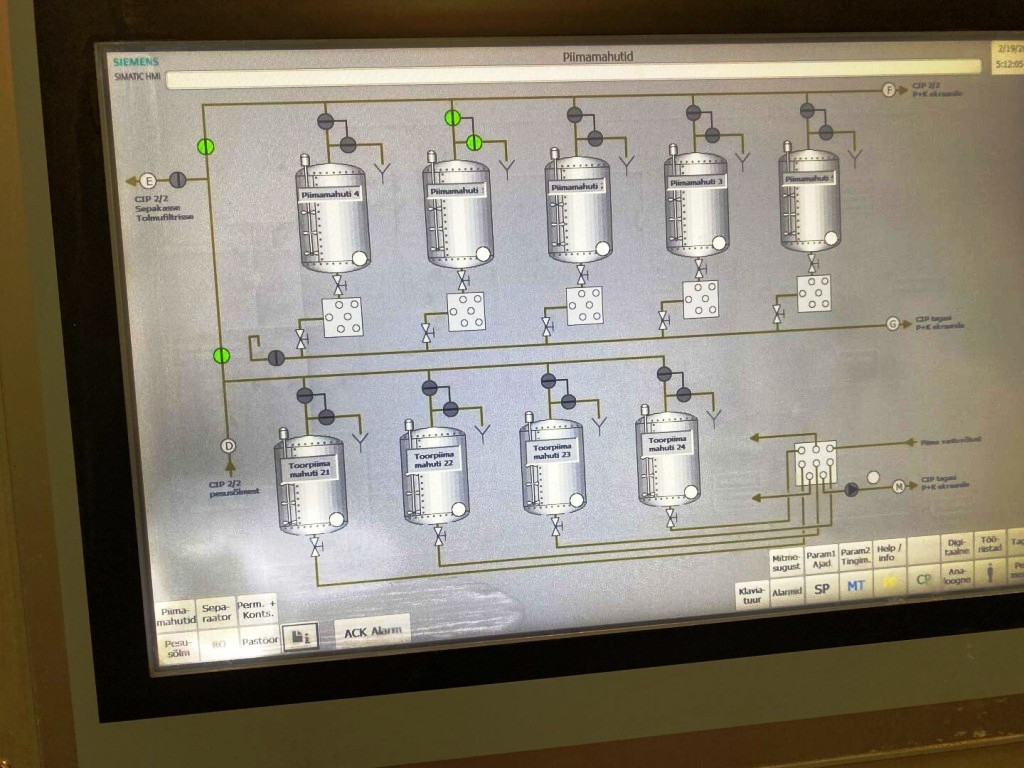

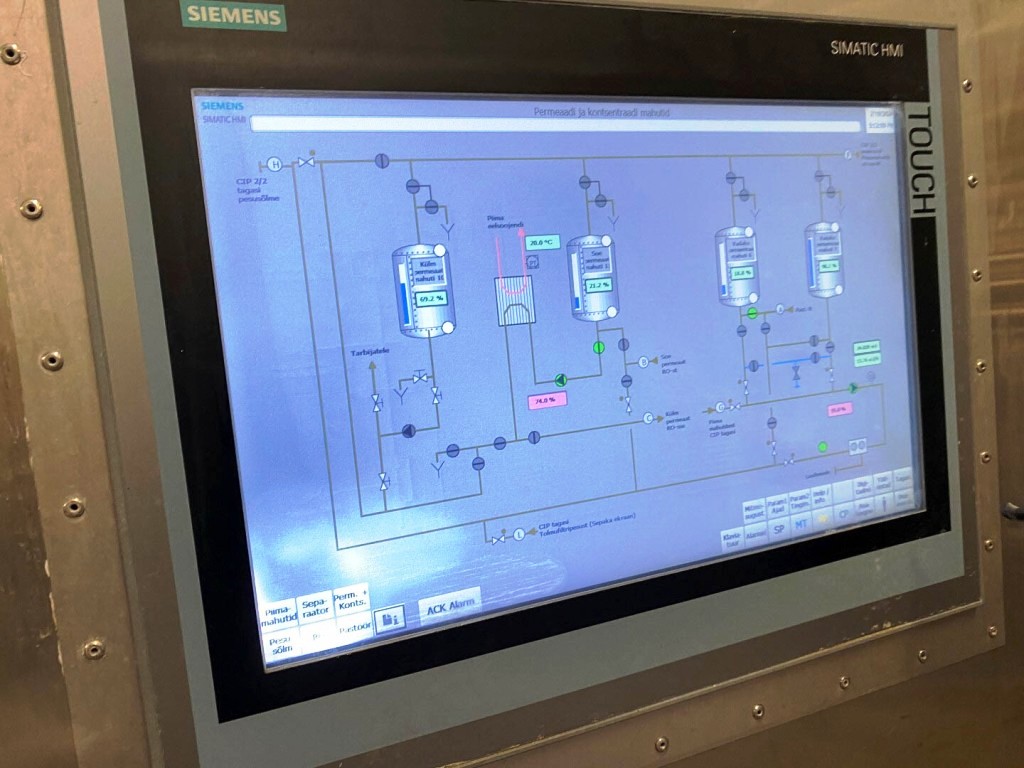

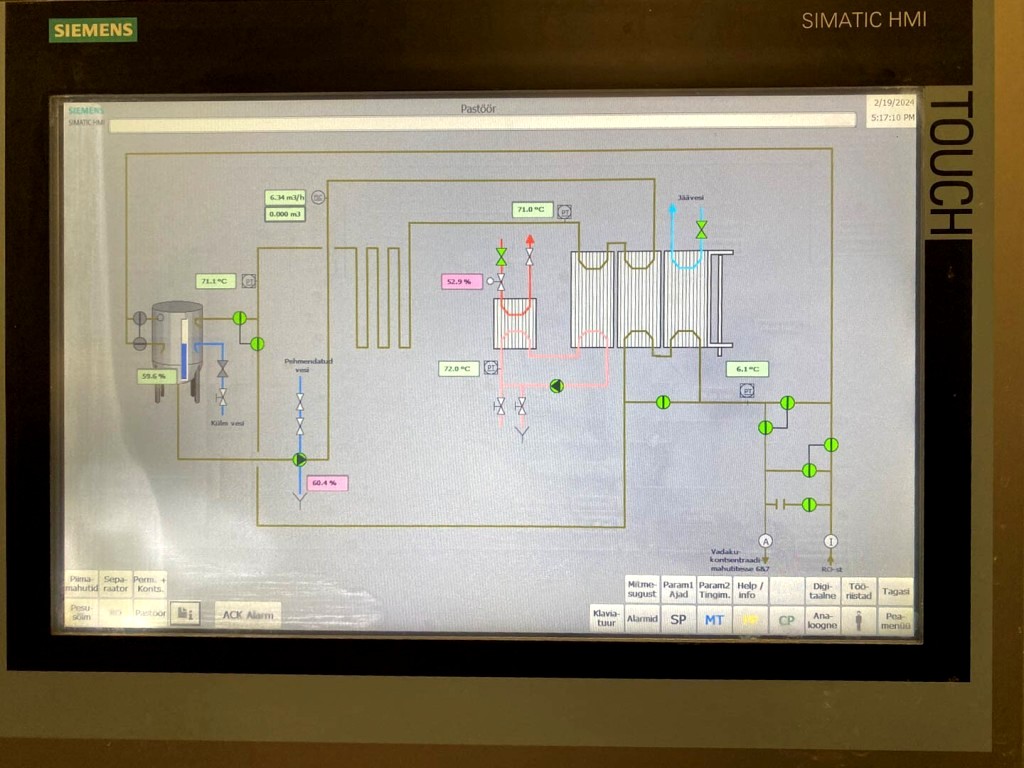

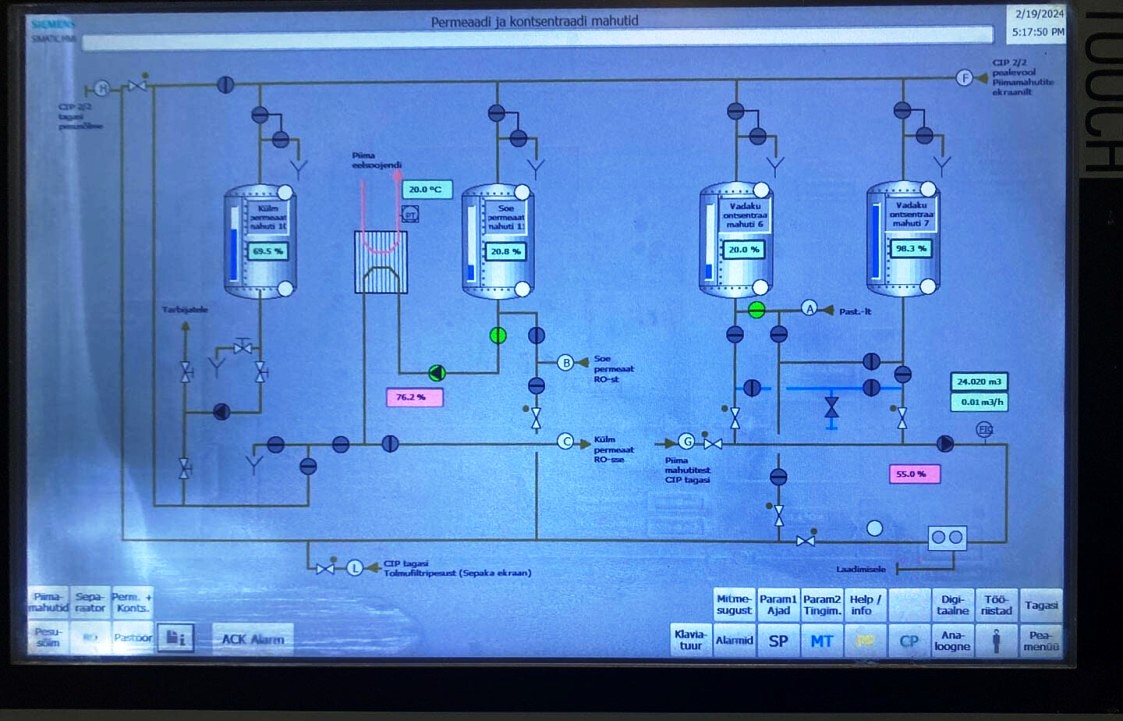

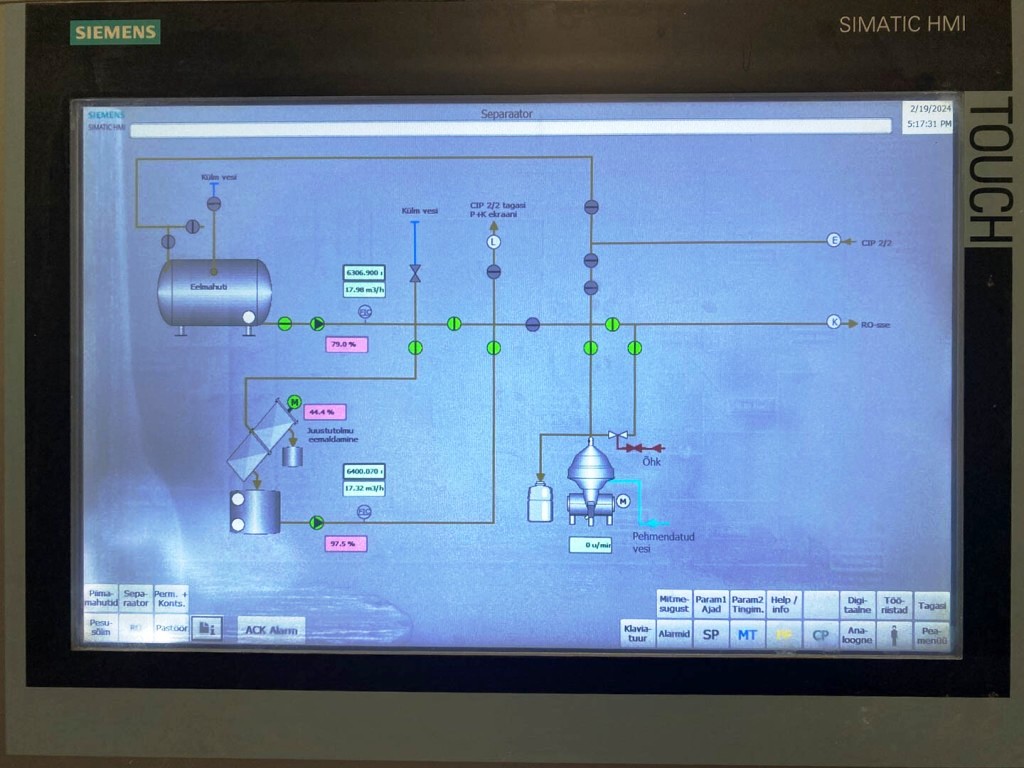

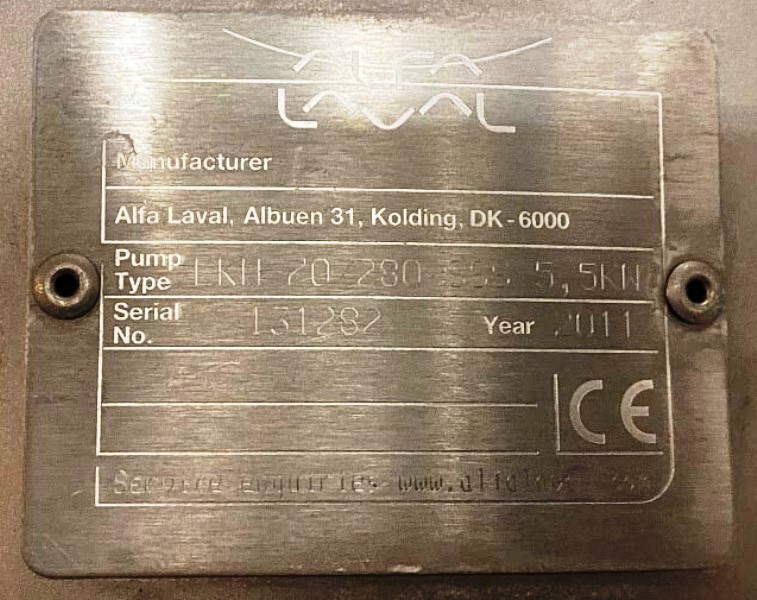

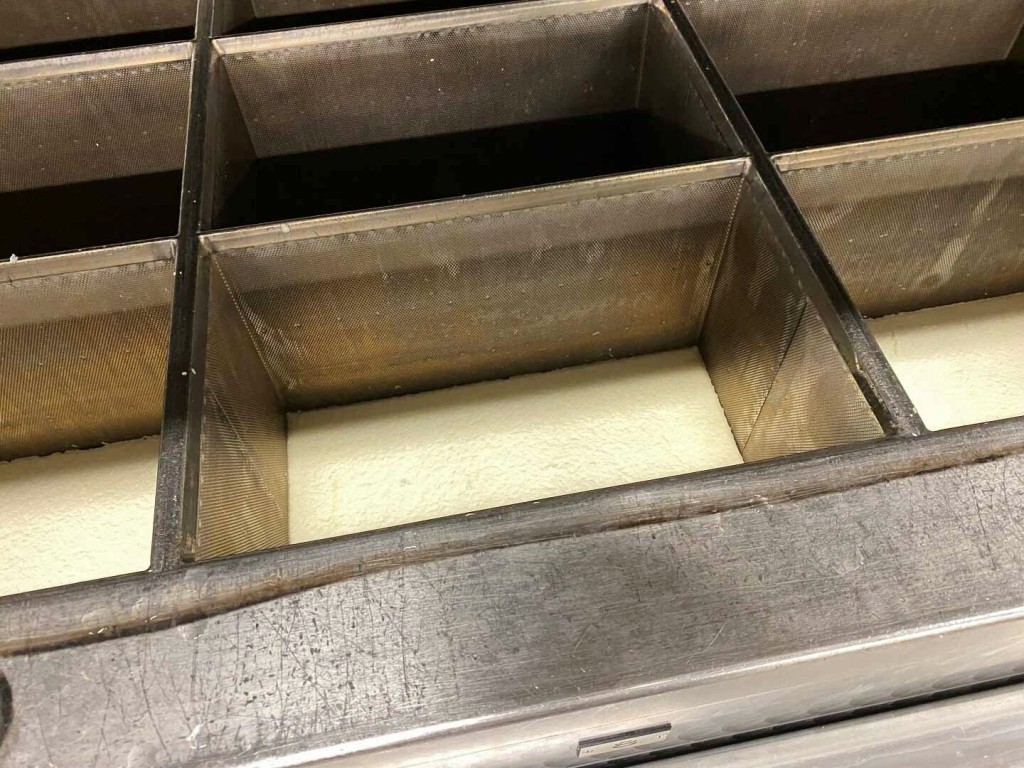

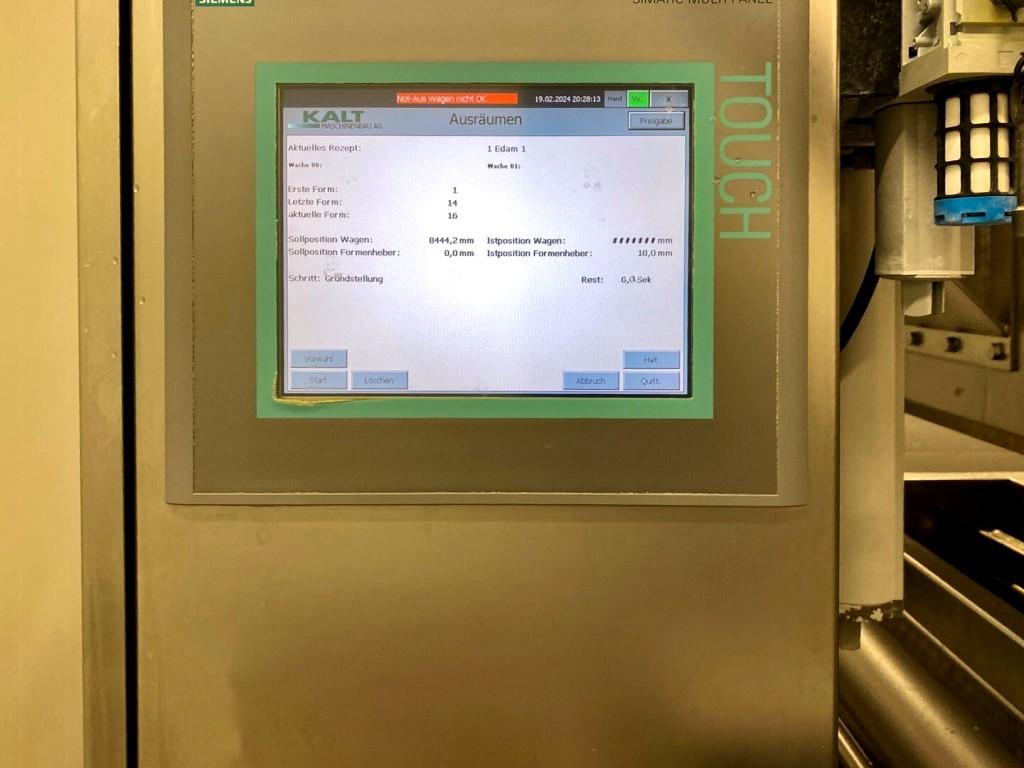

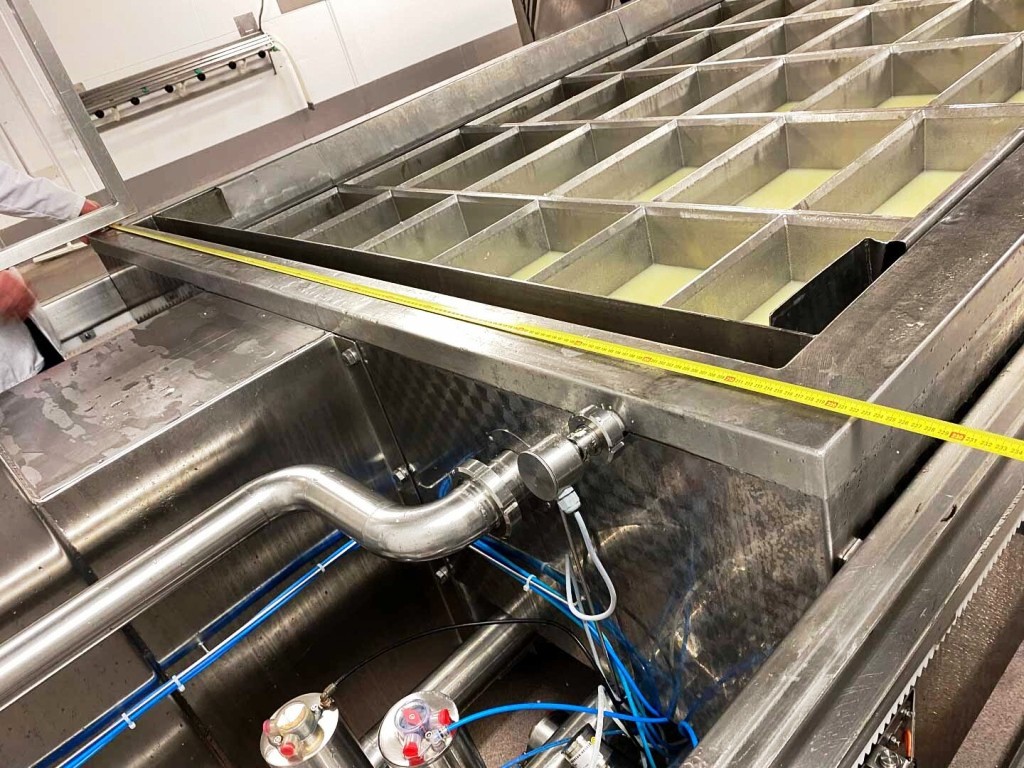

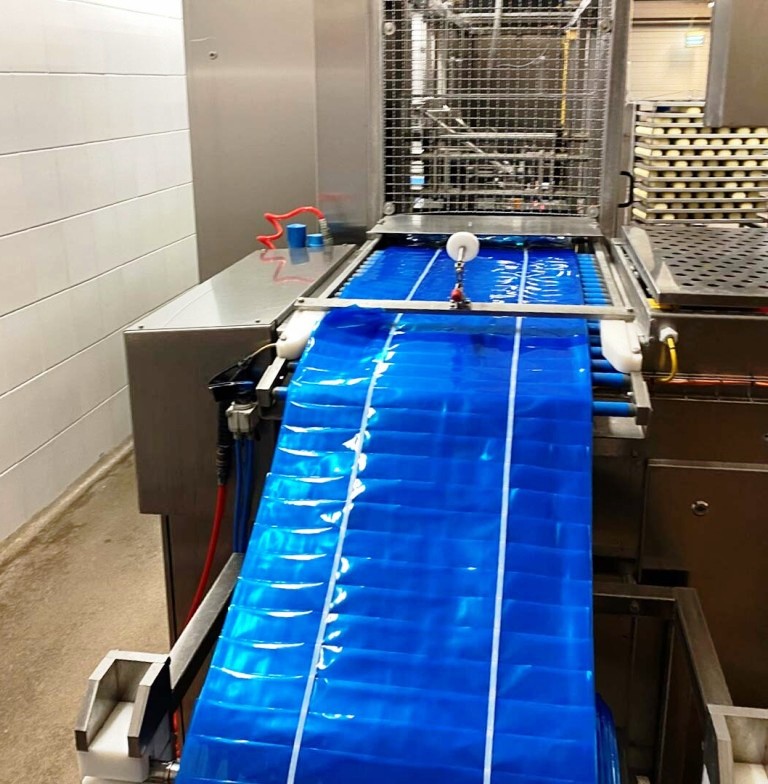

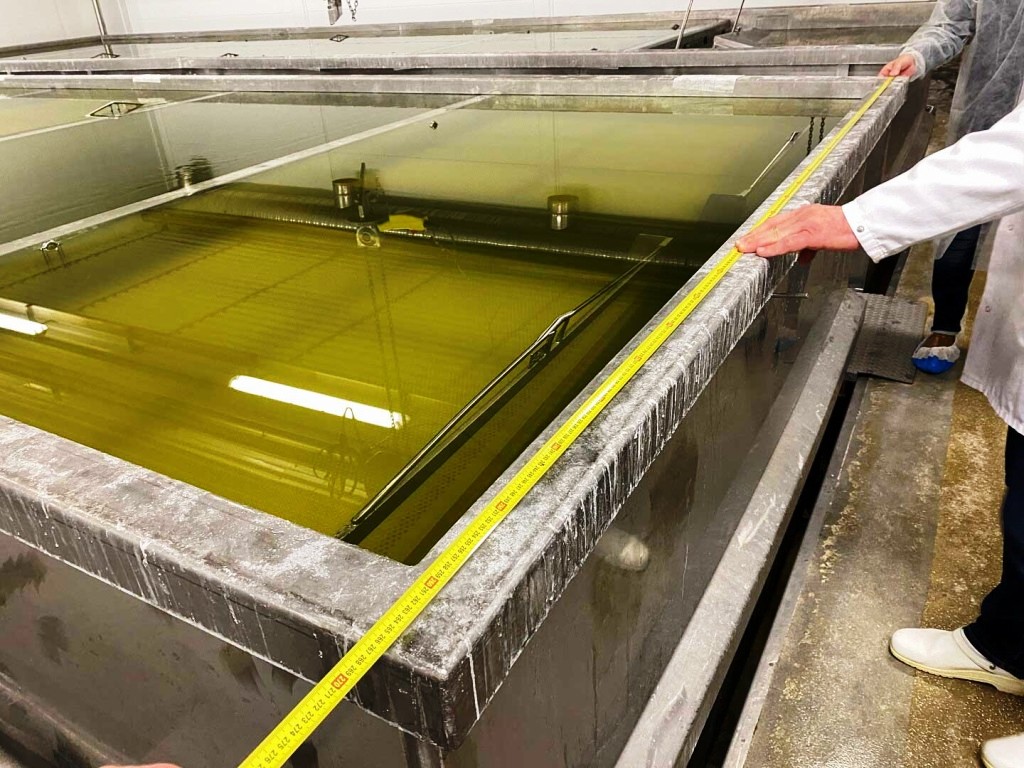

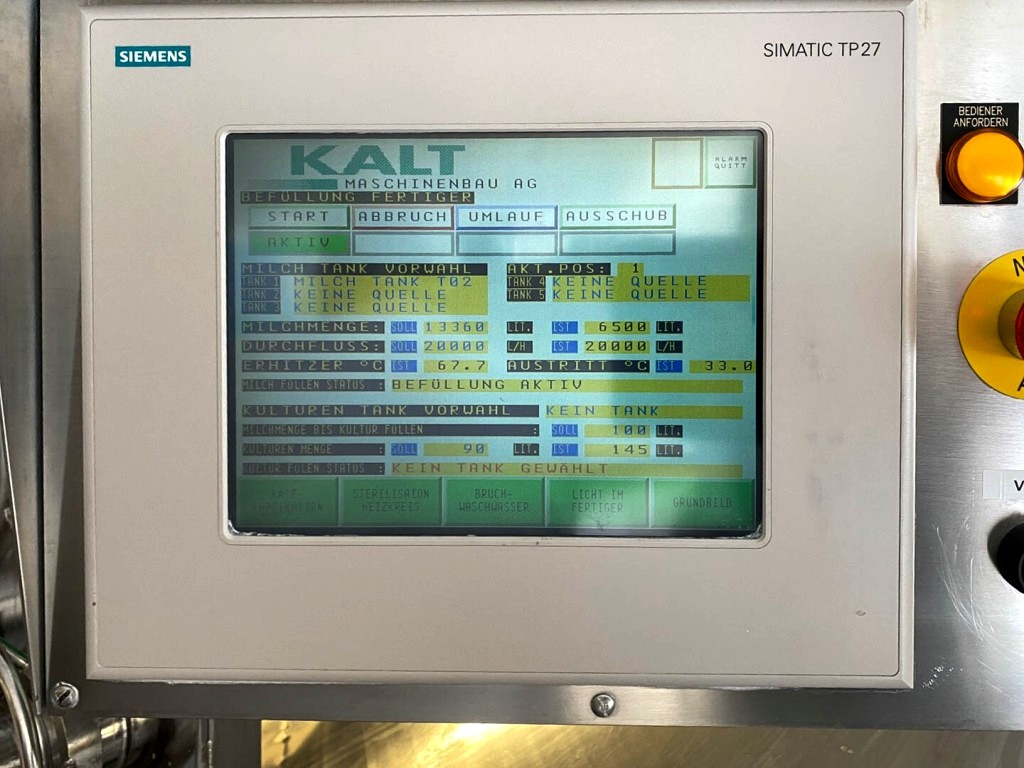

3 milk reception stations, raw milk storage tanks, 15.000 LPH milk pasteurizer, MSA 100 whey skimmer, 2 CSE 140 bactofuges, cream pasteurizer, milk buffer tanks, pasteurizer, 3 Kalt cheese vats, 2 Kassette Presse cheese draining and pressing system, warm water tank, bulk starter preparation system, brine area with SS vats and brine cages, whey treatment area with MSE 100 whey skimmer and MMS RO concentrator, whey evaporator with thermal vapor compression, whey concentrate storage and dispatch system, 2 CIP systems and MBM vacuum packer with all piping valves, tools controls and manuals. Software by Kalt and MSS Intl., Switzerland. The line was stopped in March 2024 and run till that moment on normal capacity and was well maintained. Daily capacity of the factory was approx. 270,000 liters of milk resulting in 19 batches of 84 cheeses = 1.596 cheeses of 15 kg per day. Resulting in approx. 24 tons of cheese per day. Type of cheese: Semi hard like Gouda, Edam, Maasdam, Dambo and Cagliata. The first option is to sell the unit complete as 1 lot. Dismantling, transport, upgrade and start-up can be offered on request by a 3rd company.

The Kalt/GEA Westfalia 24 TPD complete cheese plant is a state-of-the-art facility designed to meet the rigorous demands of modern cheese production. With a robust infrastructure that includes three milk reception stations and raw milk storage tanks, this plant is engineered for efficiency and high throughput. The 15,000 LPH milk pasteurizer ensures that the milk is treated to the highest safety standards, while the MSA 100 whey skimmer and two CSE 140 bactofuges effectively separate whey from curds, maximizing yield and quality. The inclusion of cream pasteurizers and milk buffer tanks further enhances the plant's operational flexibility, allowing for seamless transitions between different stages of cheese production. The three Kalt cheese vats provide ample capacity for curd processing, while the Kassette Presse cheese draining and pressing system ensures optimal moisture removal and texture development in the final product.

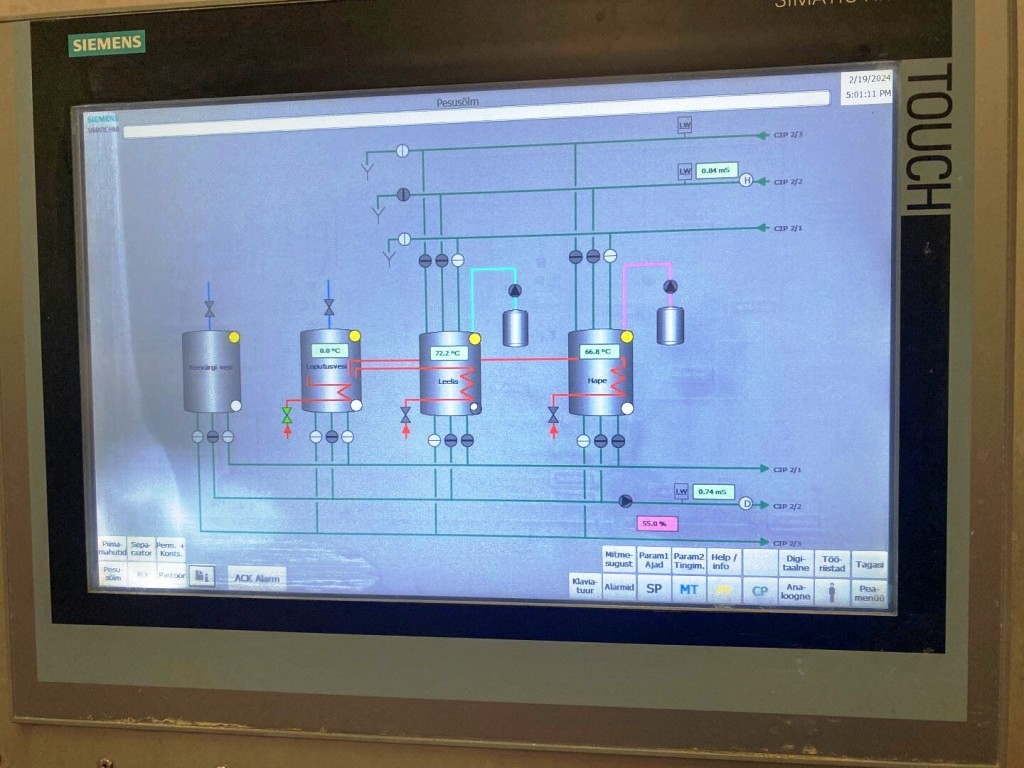

In addition to its core cheese-making capabilities, the Kalt/GEA Westfalia 24 TPD complete cheese plant features a comprehensive brine area equipped with stainless steel vats and brine cages, facilitating the salting and flavoring processes essential for semi-hard cheeses like Gouda and Edam. The whey treatment area, highlighted by the MSE 100 whey skimmer and MMS RO concentrator, underscores the plant's commitment to sustainability by efficiently managing whey by-products. The whey evaporator with thermal vapor compression further enhances operational efficiency by reducing energy consumption during whey processing. With a daily capacity of approximately 270,000 liters of milk, this plant can produce up to 24 tons of cheese per day, making it an ideal choice for large-scale cheese manufacturers looking to expand their production capabilities. The inclusion of two CIP systems ensures that hygiene standards are maintained, while the MBM vacuum packer streamlines packaging operations. The complete package comes with all necessary piping, valves, tools, controls, and manuals, ensuring a smooth transition for the new owner.

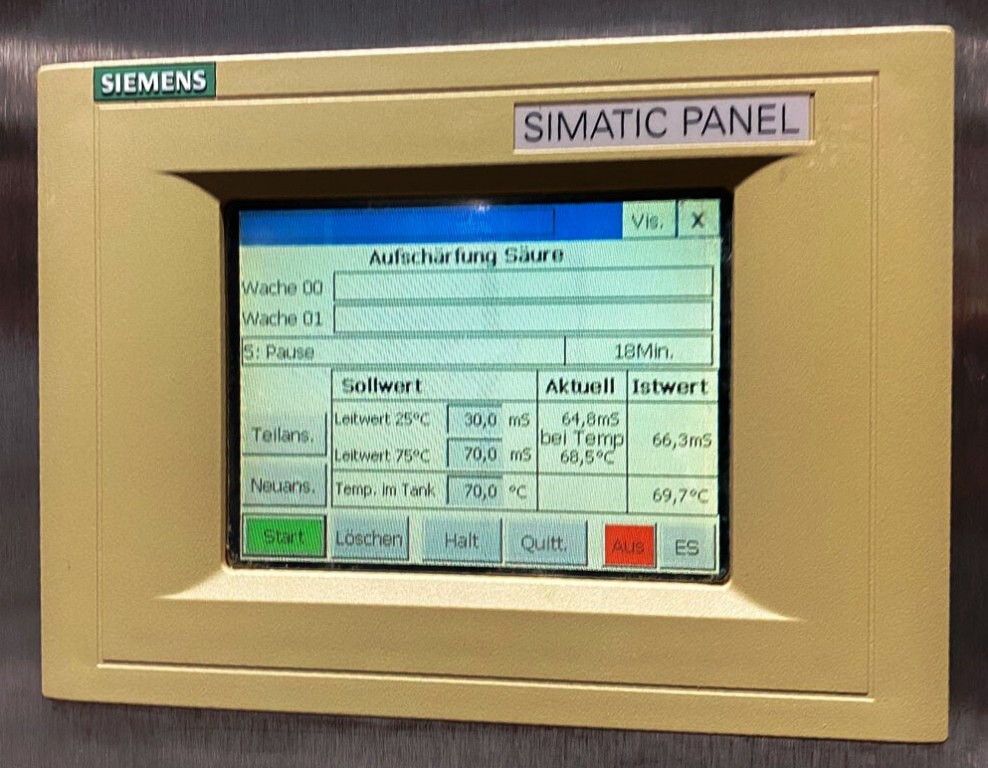

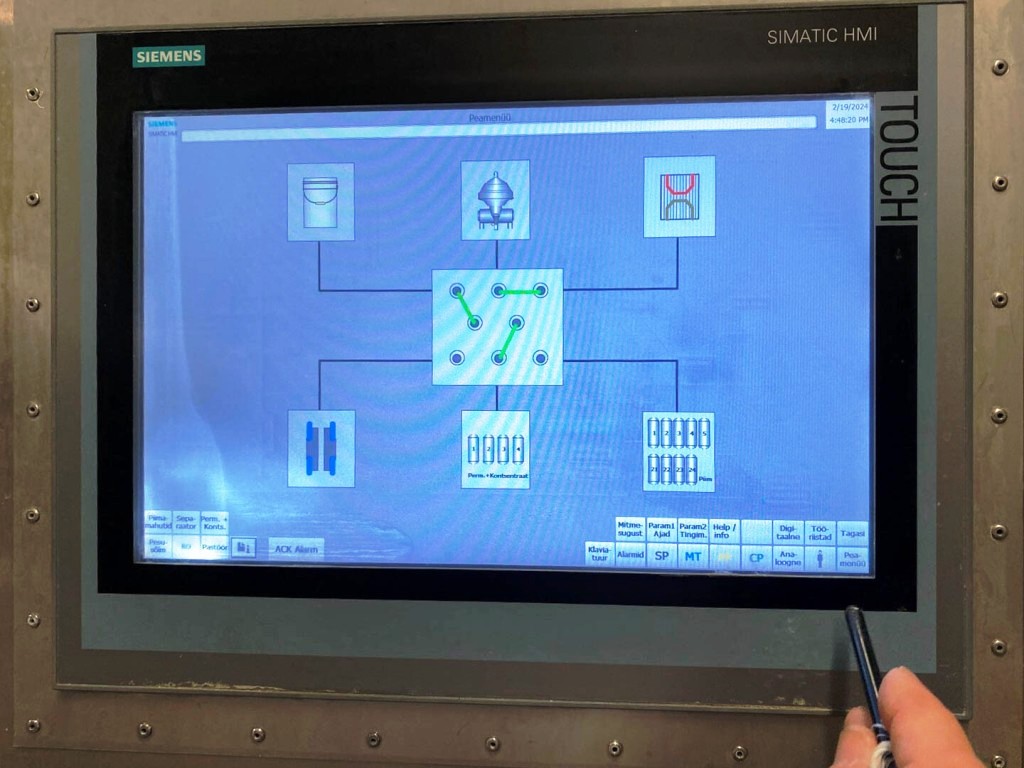

This cheese plant was operational until March 2024, having been well-maintained throughout its lifecycle, which speaks to its reliability and performance. The option to sell the unit as a complete lot provides a turnkey solution for prospective buyers. Additionally, dismantling, transport, upgrade, and start-up services can be arranged through a third-party company, ensuring that the transition to new ownership is as seamless as possible. With software support from Kalt and MSS International, Switzerland, users can expect a user-friendly interface that enhances operational efficiency and monitoring capabilities.

Key Features:

High Production Capacity, Advanced Processing Technology, Comprehensive Hygiene Systems, Sustainable Whey Management, Turnkey Solution Available