Description:

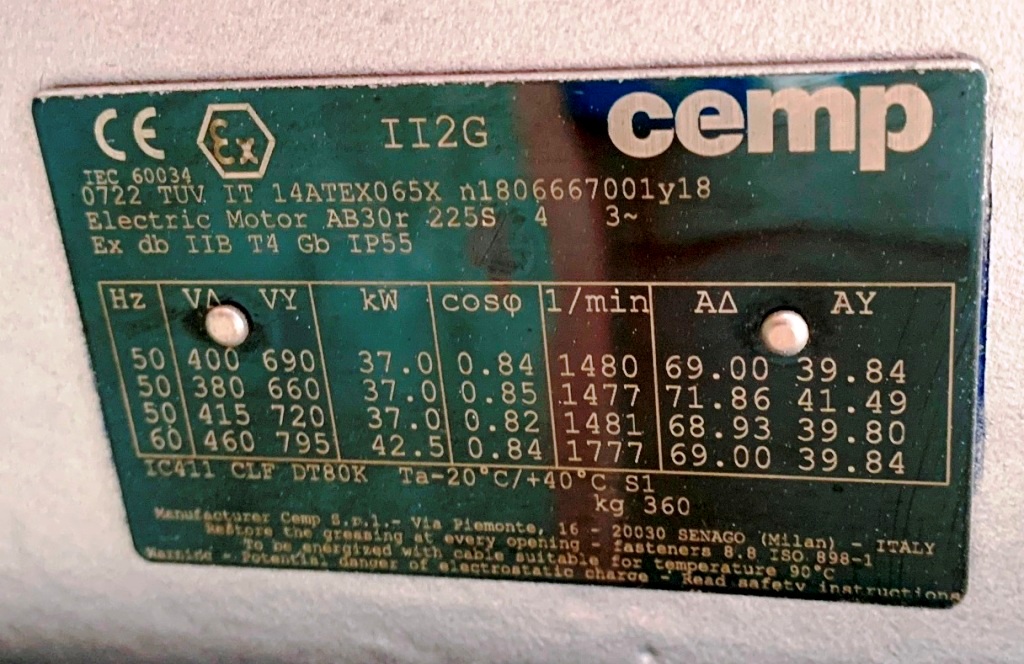

Max bowl speed 950 RPM, 1250 x 650mm basket, 400 L capacity. Bottom dump, vapor tight, 37 XP KW motor 400/690/3/50/1480 RPM, broad knife peeler, feed and wash pipes, rotating spray head, manhole cover with large light and sight glasses, filtrate discharge pipe, basket rinser, unitized on an inertia base with Visco-dampeners, connections for inert gas and lubrication. No control panel. Reconditioned. Located in Europe.

The Krauss-Maffei VZU 125/2.5 ATEX perforate basket centrifuge, 316L SS. is engineered for high-efficiency separation processes in industries that demand stringent safety and performance standards. With a maximum bowl speed of 950 RPM and a substantial basket size of 1250 x 650 mm, this centrifuge is capable of handling a significant volume of material, boasting a capacity of 400 liters. The design incorporates a bottom dump feature, ensuring that the discharge process is both efficient and clean, while the vapor-tight construction minimizes the risk of contamination and enhances operational safety. The robust 37 XP KW motor, operating at 400/690/3/50/1480 RPM, provides the necessary power for effective separation, making it ideal for applications in chemical, pharmaceutical, and food processing industries where reliability is paramount.

In addition to its impressive performance specifications, the Krauss-Maffei VZU 125/2.5 ATEX perforate basket centrifuge is equipped with a broad knife peeler, which facilitates the removal of solids from the liquid phase, enhancing the overall efficiency of the separation process. The inclusion of feed and wash pipes, along with a rotating spray head, ensures thorough cleaning and optimal material handling. The manhole cover features large light and sight glasses, allowing for easy monitoring of the centrifuge's operation and the condition of the materials being processed. Furthermore, the filtrate discharge pipe and basket rinser contribute to a streamlined workflow, reducing downtime and maintenance needs. The unitized design on an inertia base with Visco-dampeners minimizes vibrations, enhancing stability during operation. This reconditioned unit is located in Europe, making it a valuable addition for businesses looking to enhance their processing capabilities without compromising on quality or safety.

Key Features:

High-Speed Performance, Durable Construction, Efficient Separation, User-Friendly Design, Enhanced Safety Features