Description:

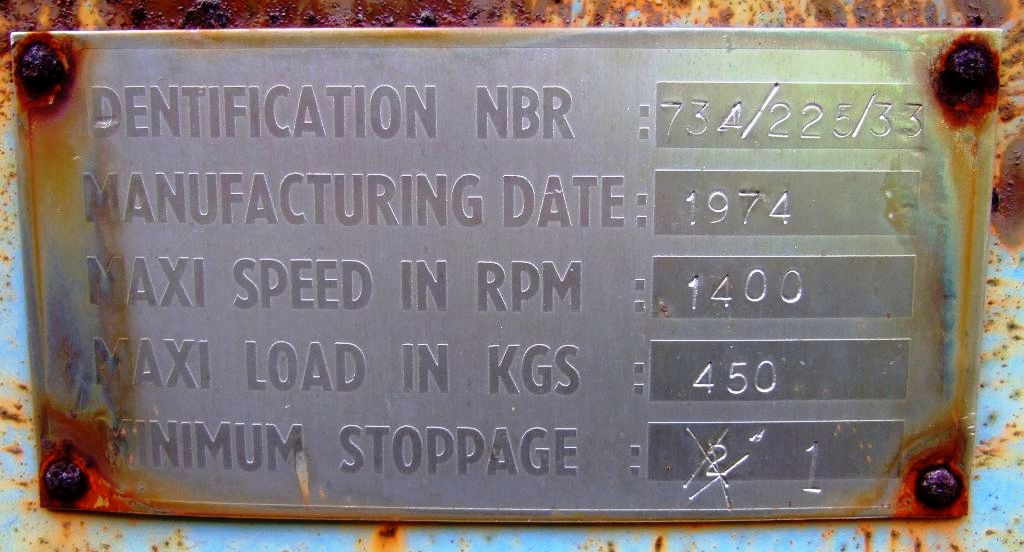

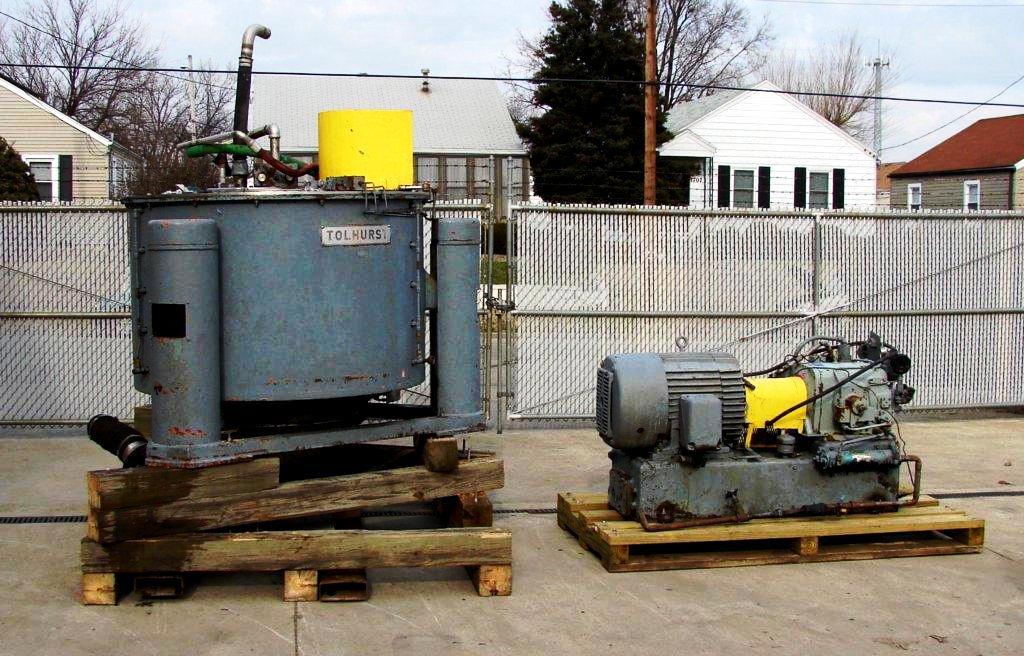

Max bowl speed 1400 RPM, 1370 x G, 1250 x 800mm basket ID, max load 450 kg, single-motion pneumatic plow, feed and rinse tubes. Missing 75 HP motor. 1974 vintage. Reportedly reconditioned. Located in UK.

The Robatel DTS-1250-K2 solid basket centrifuge, 304SS. is engineered for high-efficiency separation processes, making it an ideal choice for various industrial applications. With a maximum bowl speed of 1400 RPM and a centrifugal force of 1370 x G, this centrifuge is capable of handling substantial loads with precision. The basket dimensions of 1250 x 800mm provide ample space for processing, accommodating a maximum load of 450 kg. This robust design ensures that the centrifuge can effectively separate solids from liquids, optimizing productivity in operations where separation is critical. The single-motion pneumatic plow enhances the discharge process, allowing for efficient removal of separated solids while minimizing downtime between batches. Additionally, the integrated feed and rinse tubes facilitate streamlined operations, ensuring that the centrifuge can be easily integrated into existing production lines.

Manufactured in 1974, the Robatel DTS-1250-K2 has reportedly undergone reconditioning, which enhances its reliability and performance. The use of 304 stainless steel in its construction not only provides excellent corrosion resistance but also ensures durability in demanding environments. This material choice is particularly beneficial for industries where hygiene and cleanliness are paramount, such as food processing, pharmaceuticals, and chemical manufacturing. The centrifuge's design allows for easy access to components, simplifying maintenance and reducing operational interruptions. While it is currently missing a 75 HP motor, this can be easily sourced to restore the centrifuge to its full operational capacity. Overall, the Robatel DTS-1250-K2 solid basket centrifuge presents a valuable opportunity for businesses seeking a reliable and efficient separation solution.

Key Features:

High-Speed Performance, Durable Construction, Efficient Solid-Liquid Separation, Easy Maintenance Access, Integrated Feed and Rinse Tubes