Description:

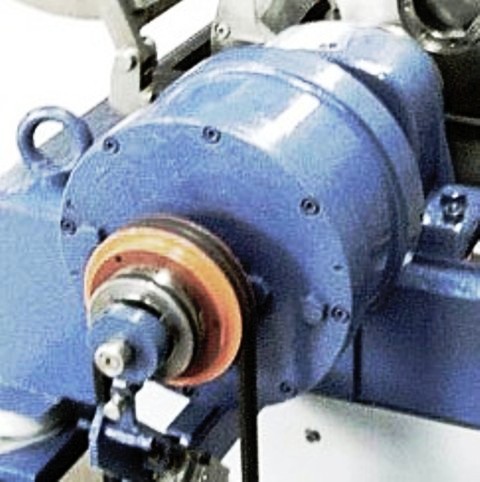

Max bowl speed 2000 RPM, 2270 x G, rated @ 540 GPM, FRP top cover, 10 degree tiled beach, 360 degree cake discharge, half-moon plate dams, 15" single lead STC-tiled quasi-axial conveyor, P300 95:1 gearbox and feed tube. No motors, no gearbox guard. 1980 vintage. The unit was reconditioned 6 or 7 years ago by Cenco in Iowa. It has brand new tiles on the conveyor. The bearings have been wrapped in plastic and stored indoors all this time.

The Sharples PM-95,000 Super-D-Canter centrifuge, 316SS, is engineered for high-efficiency separation processes, making it an ideal choice for various industrial applications. With a maximum bowl speed of 2000 RPM and a centrifugal force of 2270 x G, this centrifuge is capable of handling substantial volumes of material, rated at 540 GPM. The design features a FRP top cover that enhances durability while providing protection against corrosive environments. The 10-degree tiled beach design optimizes the separation process, ensuring effective solid-liquid separation and maximizing throughput. Additionally, the 360-degree cake discharge system facilitates efficient removal of solids, minimizing downtime and enhancing operational efficiency.

This centrifuge is equipped with a half-moon plate dam system that aids in controlling the cake thickness, allowing for precise adjustments based on specific process requirements. The 15-inch single lead STC-tiled quasi-axial conveyor ensures consistent and reliable material transport, further contributing to the overall effectiveness of the separation process. The P300 95:1 gearbox and feed tube are designed to provide robust performance, ensuring that the centrifuge operates smoothly under varying load conditions. Although the unit is vintage from 1980, it has been meticulously reconditioned by Cenco in Iowa approximately six or seven years ago, ensuring that it meets modern operational standards. The brand new tiles on the conveyor and the careful storage of the bearings wrapped in plastic highlight the commitment to maintaining the equipment in optimal condition, ready for immediate deployment in demanding industrial environments.

Key Features:

High-Speed Performance, Durable Construction, Efficient Cake Discharge, Versatile Application, Reconditioned for Reliability