STOCK # 11496

Description:

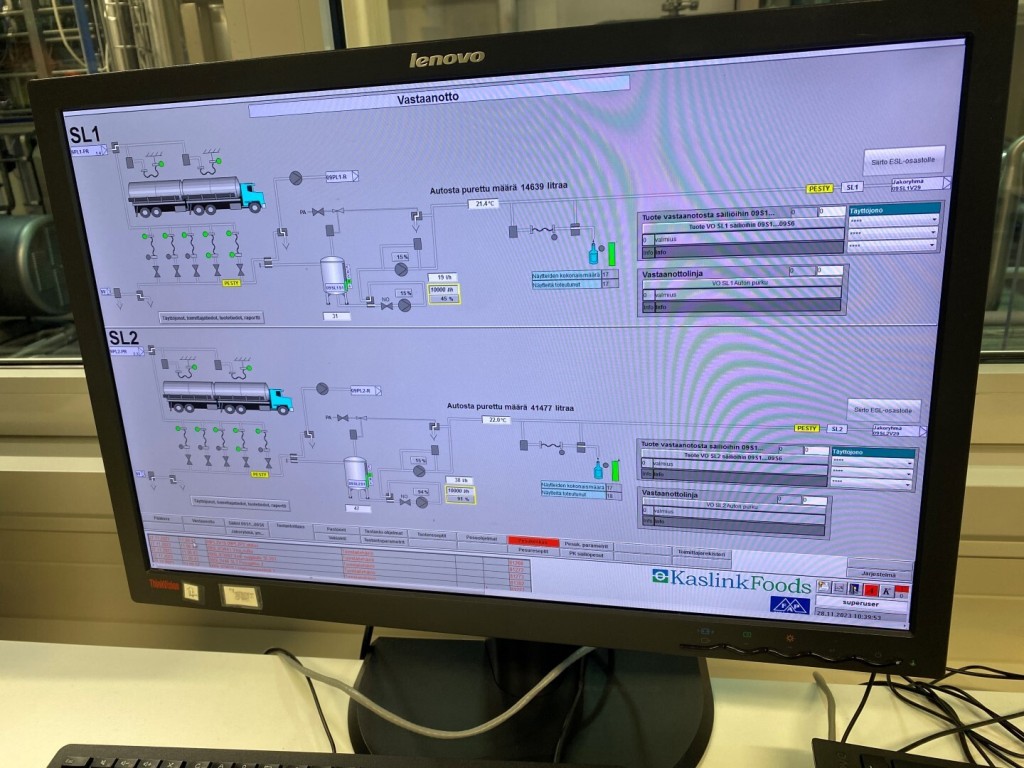

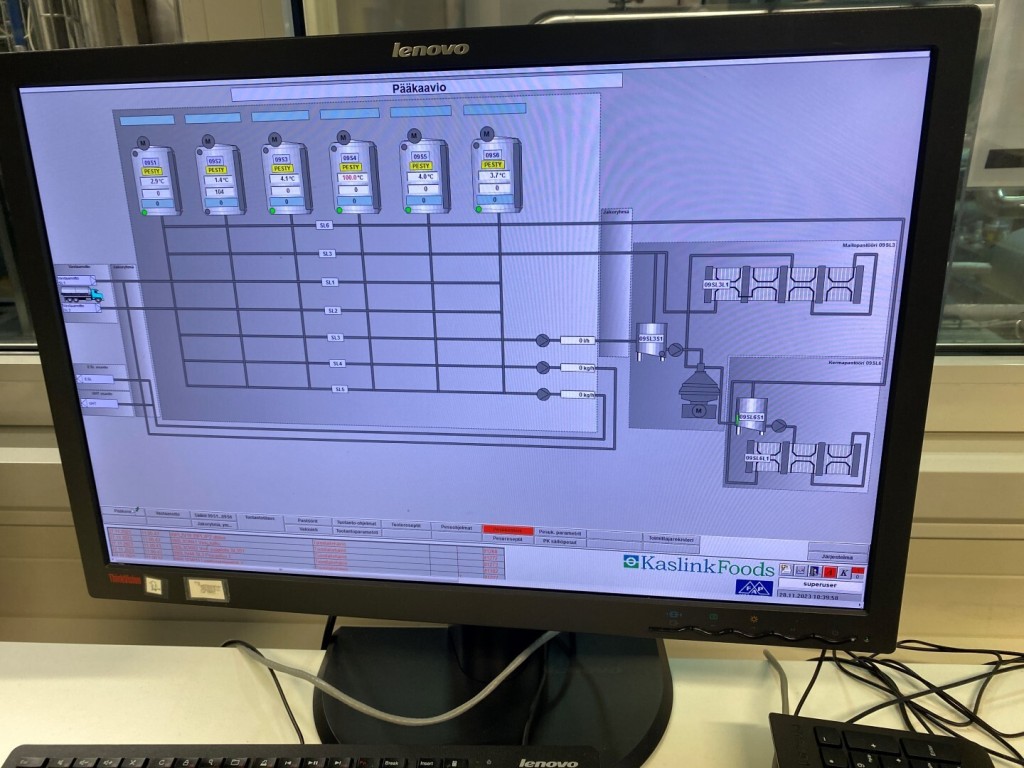

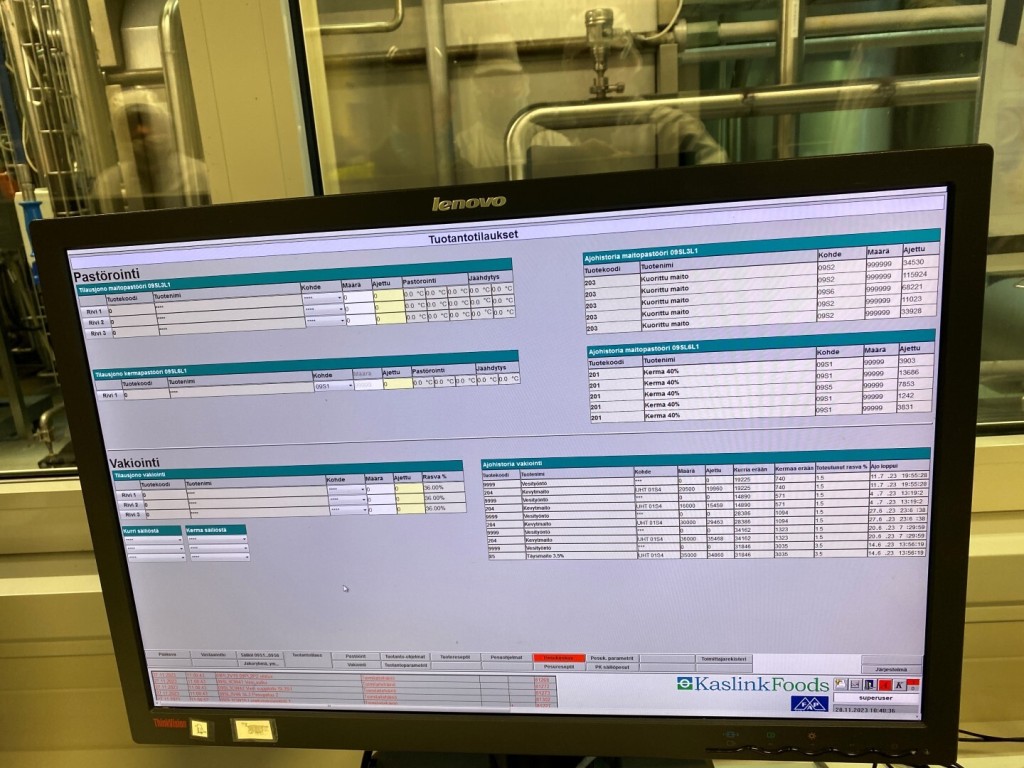

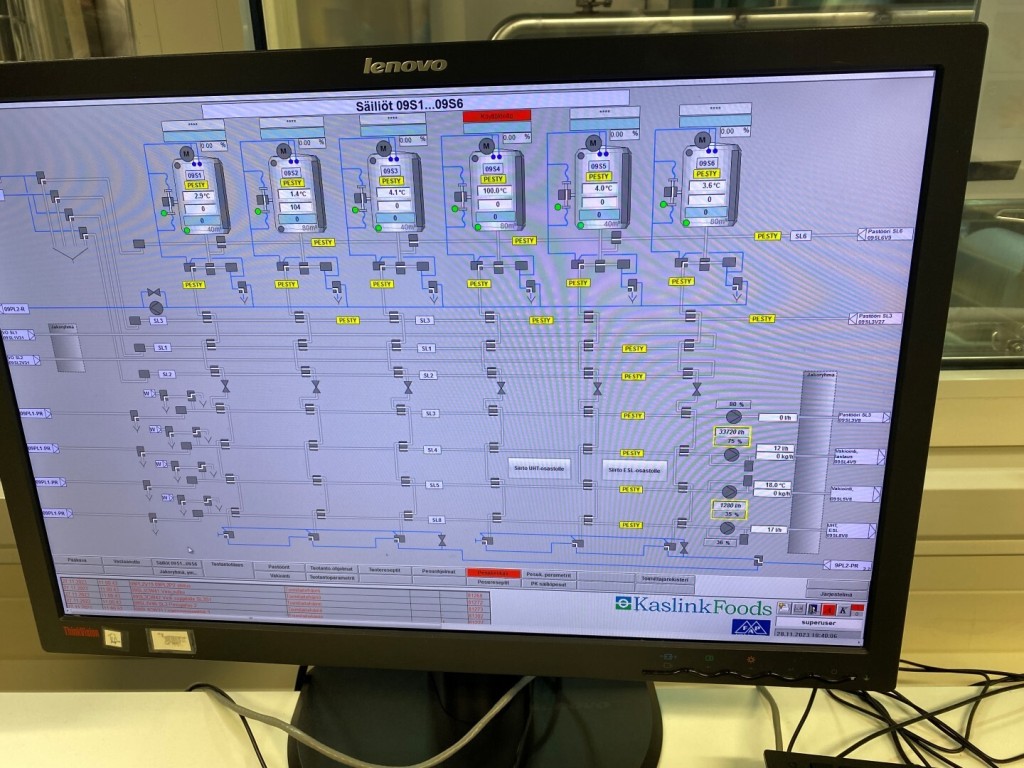

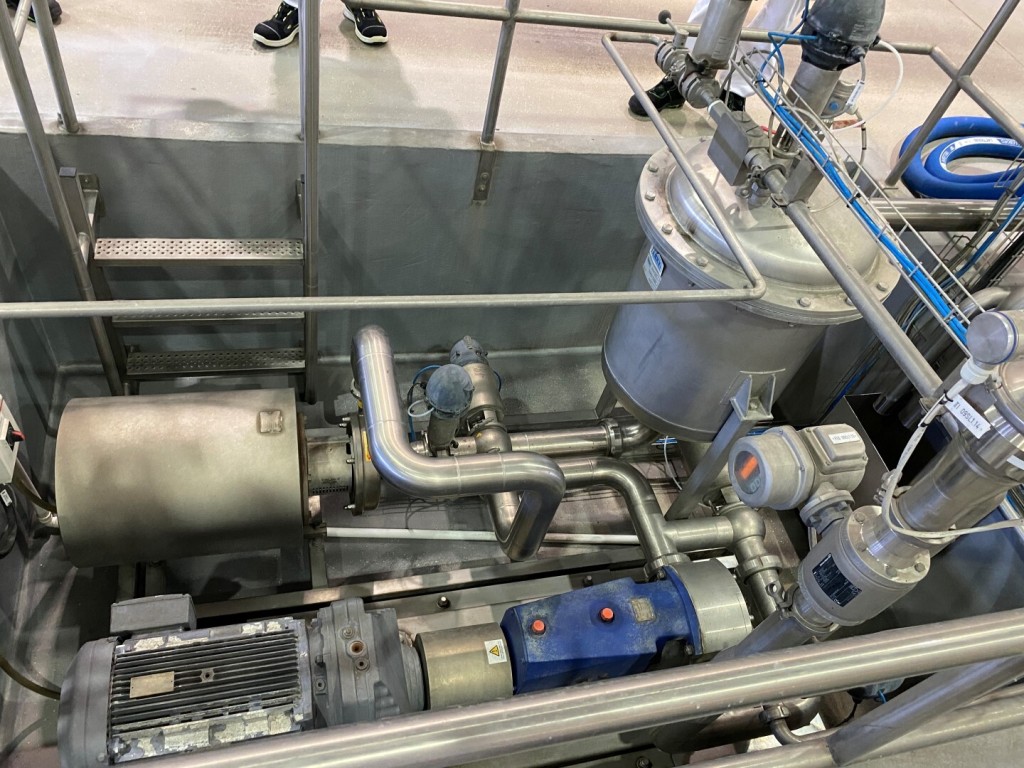

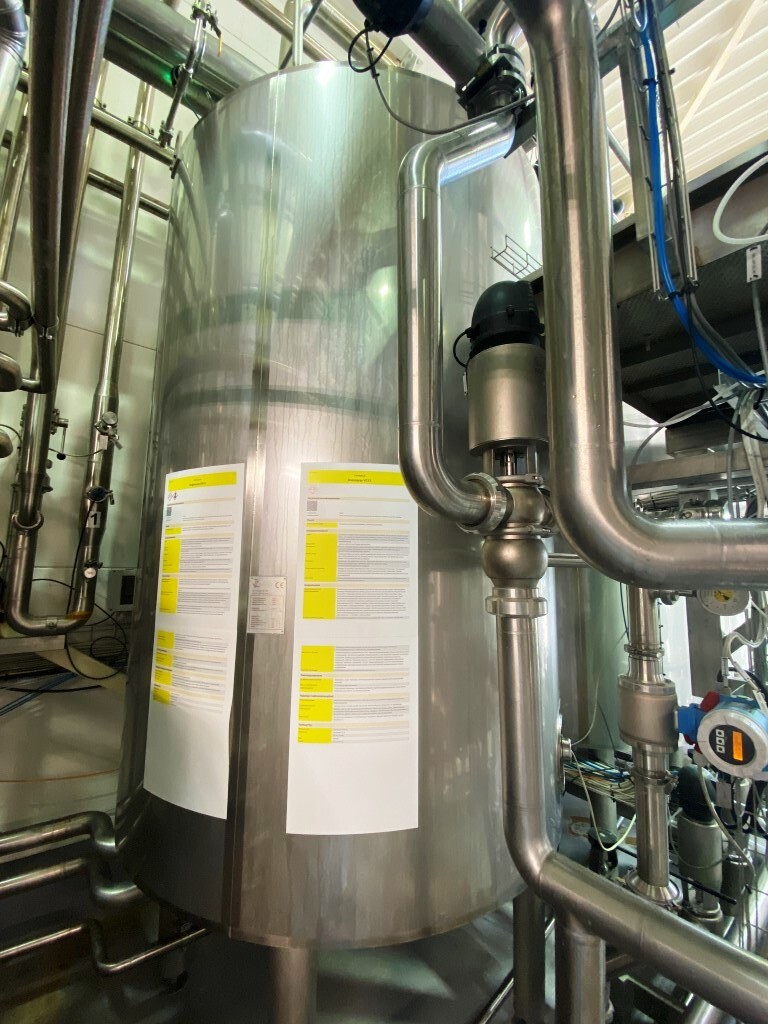

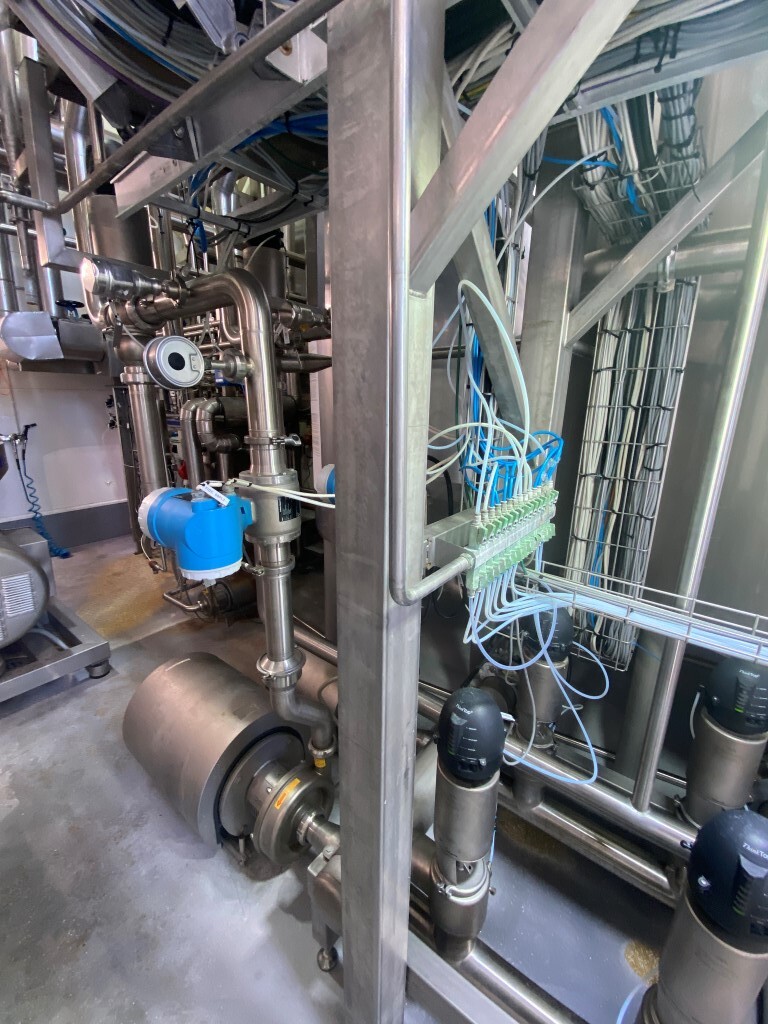

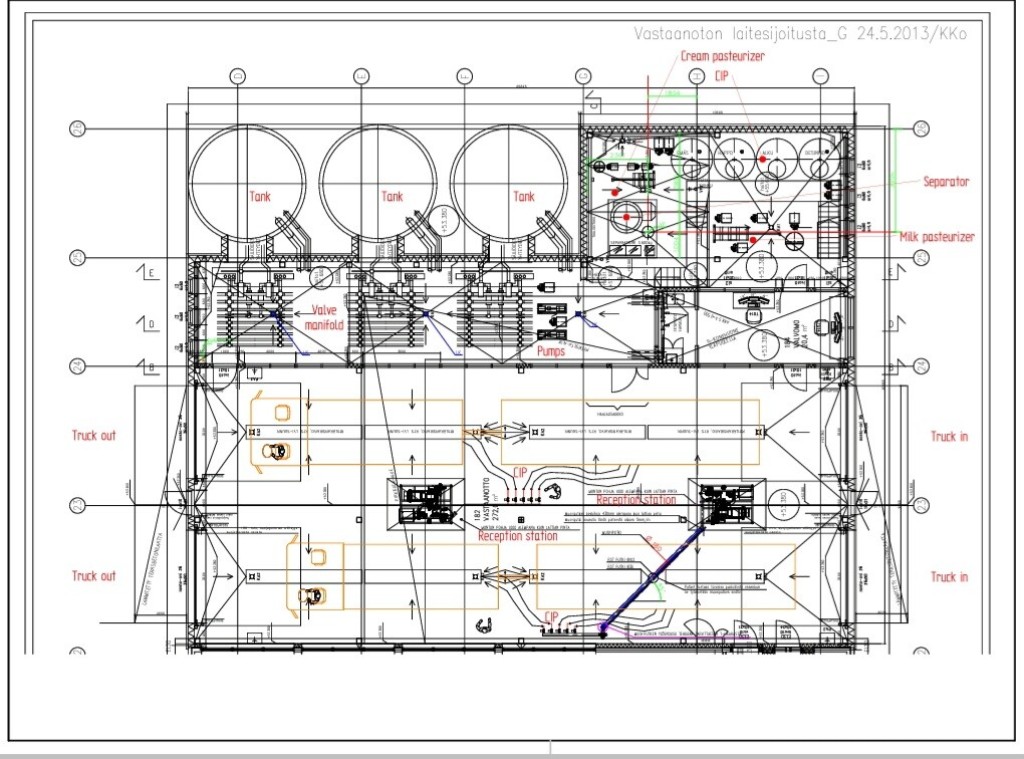

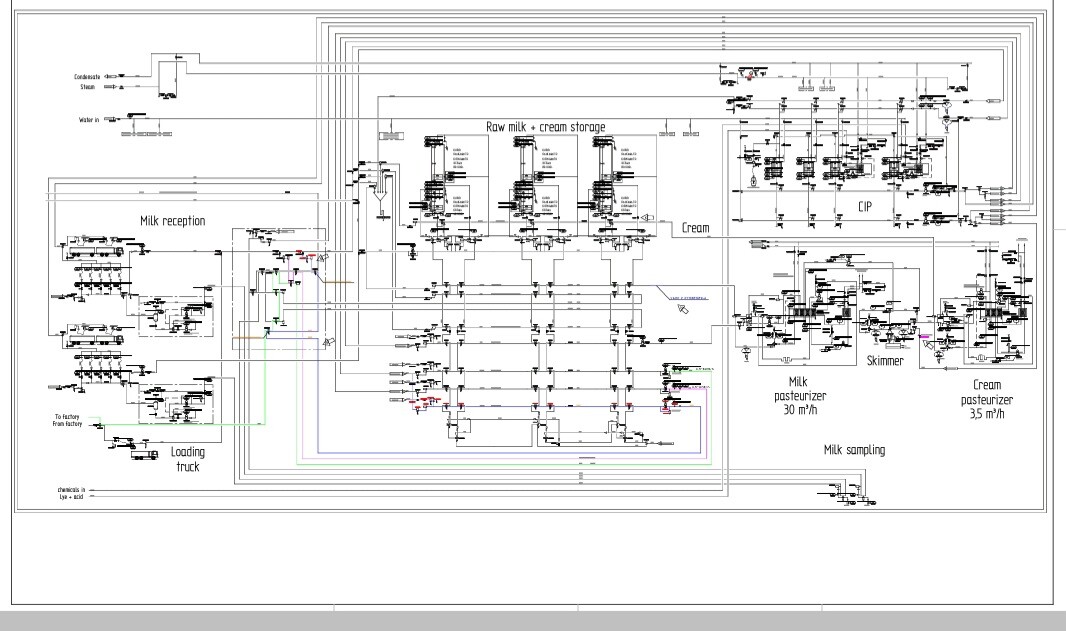

Complete milk reception and processing plant. Components are supplied by by Tetra Pak / Alfa Laval. 2 milk receptions stations. Each reception station has 5 hoses to connect to the truck, an air-eliminator, flow transmitter, temperature transmitter, Centrifugal pump for milk and lobe rotor pump for cream reception. Including valves, piping and it is all skid mounted. A full automatic milk sampling station is placed in the processing area. Capacity reception: 50.000 liter per hour milk or 30.000 liter per hour cream per set. There is 1 milk or cream send out station for re-pumping the milk and cream back into the truck. Including 2 cleaning units for milk transport trucks. Including valve manifolds in front of the raw milk and cream tanks. Flexible valve manifolds to receive raw milk and distribute it over 6 tanks and at the same time distribute pasteurized skim milk or cream from the same tanks. Including lobe pump for cream and centrifugal pump and (Mass) flow transmitters for milk standardization, and distribution to the users. Mix-proof design. The valves of the manifold are Tetra Pak Unique valves. Including 6 storage tanks. Vertical Insulated tanks placed outside with propeller agitators, sensors (level/temperature), breathers, sprays balls for CIP cleaning, tank sensors, CIP cleanable sampling valve, cove to the inside, breather insulated to the inside with drip tray. There are 2 tanks combined in 1 body each tank has a capacity of 40.000 plus 80.000 liter in separate departments on top of each other, so 3 tanks of each 120.000 liter. The tanks can be filled with raw milk or processed milk or cream . Frame work in front of tanks is included. Milk pasteurizer, temperature cycle: input: 4°C to separator at 55°C high 75°C - out at 3°C. Complete kit with balance tank, pumps, plate heat exchanger C10-KSM, valves, sensors, steam-hot water system, holding tube, interconnecting piping, flow transmitter.

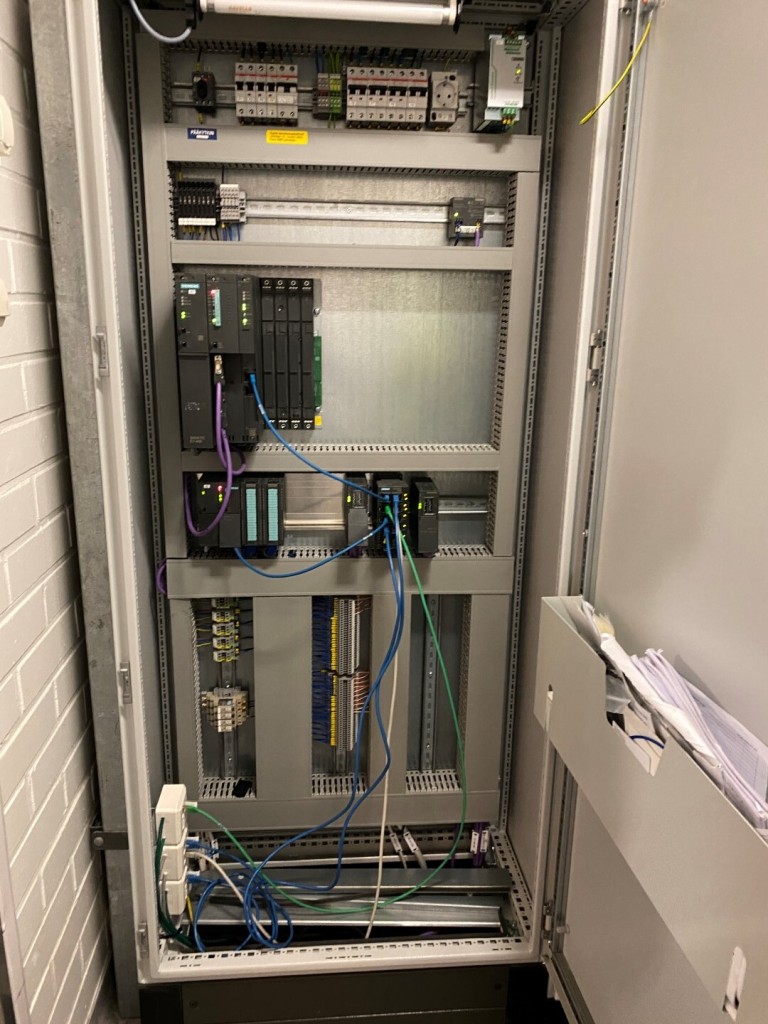

Separator – milk skimmer. Complete self-cleaning separator Tetra Pak, model: H40 with controls and tools, skid mounted. Frequency controller on the main motor, 25 KW. The separator has its own controls and communicates with the system through Profinet. Cream pasteurizer. Temperature cycle: in from separator 55°C-high 95°C-out 6°C. Capacity: up to 3.500 liter of cream pasteurization per hour. Complete kit with balance tank, pumps, plate heat exchanger C6-SR, valves, sensors, steam-hot water system interconnecting piping. CIP Unit. Complete CIP unit with 4 tanks of 3.300 liter each. Lye, acid and clean water tank are insulated. Breather in stainless steel to outside. 2 outgoing lines to be able to clean 2 items at same time. Including pumps, valves, interconnecting piping, chemical dosing of disinfectant to clean water tank. Controls: Complete with 5 field cabinets 5 remote IO boxes, 2 main PLC Siemens S7 (1 for processing and 1 for CIP), 2 Siemens HMI Touch screen panels at the reception unit, and ABB frequency converters on all pumps. All documentation flowcharts and software.

Excluding: Chemical dosing system of lye and acid (was centralized) and frame work in front of CIP. The line is still installed in Finland, can be visited on request. Located in Europe.

Add to Cart