Description:

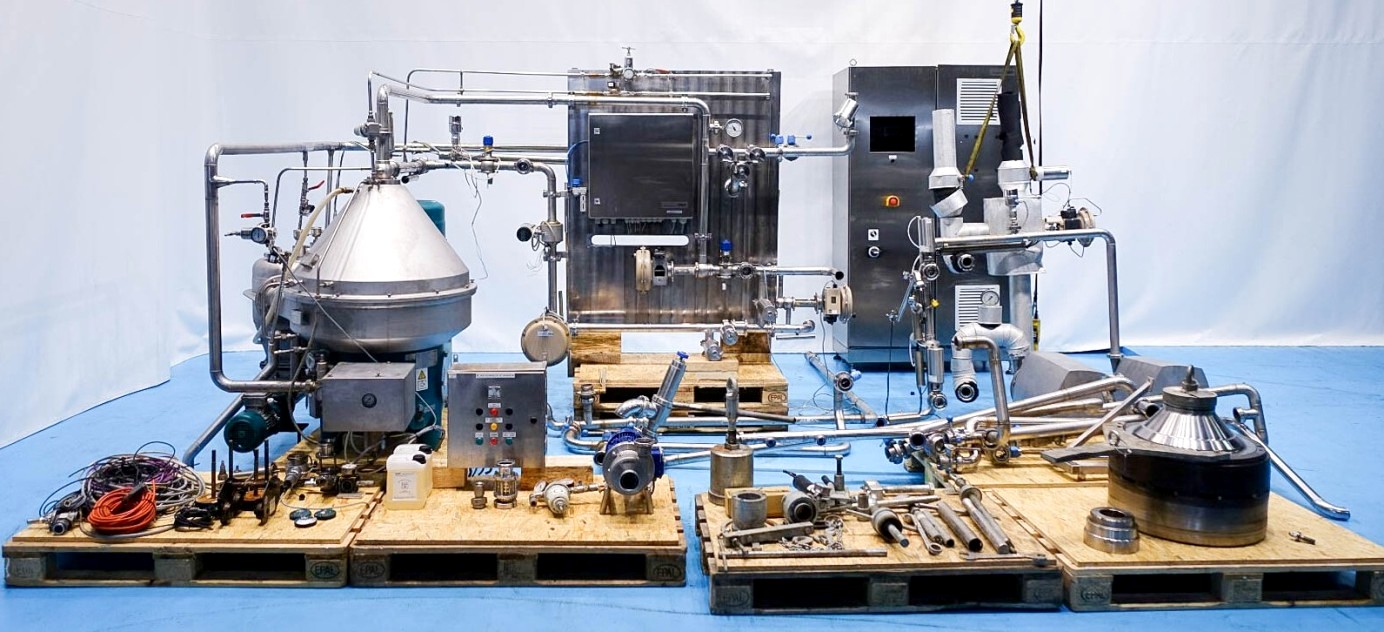

Max bowl speed 7250 RPM, rated @ 20,000 LPH, 10 L solids space, 6 bar discharge pressure. 37 KW motor 400/3/50/2955 RPM, solids cyclone with a Seepex progressive cavity pump, (3) centrifugal pumps, piping, CO2 injection valve for blanketing, turbidity sensor, pressure transmitter, vibration sensor, flow transmitter, flow control valves, bypass valve, sampler on in and outlet, water harness, Siemens PLC control panel with VFDs, tools and manuals. 2011 vintage. Excellent condition. Located in Europe.

The Westfalia GSE 75-06-177 Hydrostop beer clarifier centrifuge, 316SS, is engineered for high-efficiency separation processes in the brewing industry. With a maximum bowl speed of 7250 RPM and a rated throughput of 20,000 liters per hour, this centrifuge is designed to handle large volumes of beer while ensuring optimal clarity and quality. The unit features a 10-liter solids space, allowing it to effectively separate solids from liquids, thus enhancing the overall quality of the final product. The 6 bar discharge pressure ensures that the clarified beer is efficiently expelled from the system, minimizing downtime and maximizing productivity. The advanced design of this centrifuge not only improves the clarity of the beer but also contributes to the overall flavor profile by removing unwanted particulates and yeast residues that can affect taste.

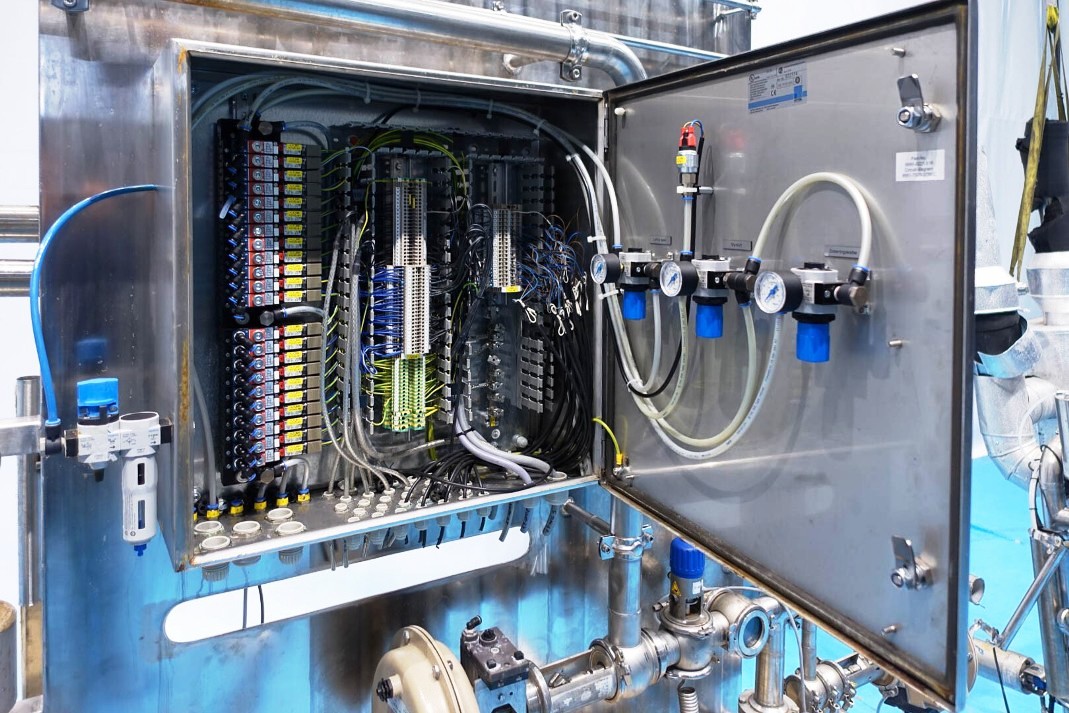

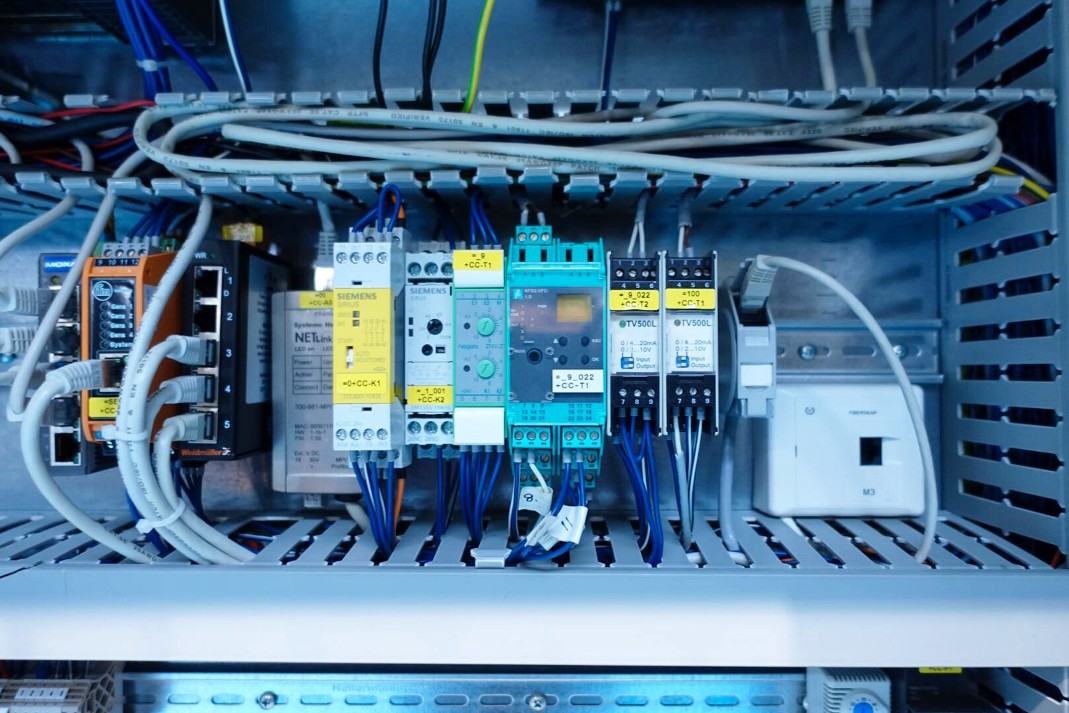

Equipped with a robust 37 KW motor operating at 400/3/50/2955 RPM, the Westfalia GSE 75-06-177 is built for reliability and performance. The integration of a solids cyclone and a Seepex progressive cavity pump, along with three centrifugal pumps, ensures a seamless operation that can handle varying flow rates and solids concentrations. The inclusion of a CO2 injection valve for blanketing is a significant feature that helps maintain the quality of the beer during processing by preventing oxidation. Additionally, the system is outfitted with essential monitoring devices such as a turbidity sensor, pressure transmitter, vibration sensor, and flow transmitter, which provide real-time data to optimize the separation process. The Siemens PLC control panel with variable frequency drives (VFDs) allows for precise control over the centrifuge's operation, making it easier to adjust settings based on specific production needs.

This 2011 vintage centrifuge is in excellent condition and is located in Europe, making it a valuable asset for breweries looking to enhance their production capabilities. The inclusion of tools and manuals ensures that operators can maintain and troubleshoot the equipment effectively, minimizing operational disruptions. With its durable 316 stainless steel construction, the Westfalia GSE 75-06-177 is designed to withstand the rigors of industrial use while maintaining hygiene standards essential in the brewing process.

Key Features:

High-Speed Performance, Robust Motor, Advanced Monitoring Systems, Durable Stainless Steel Construction, Efficient Separation Process