Description:

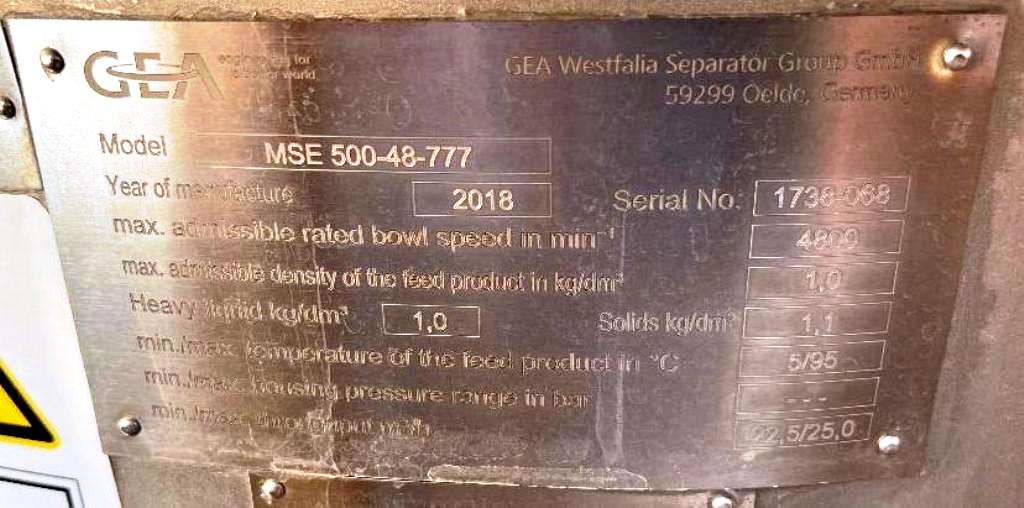

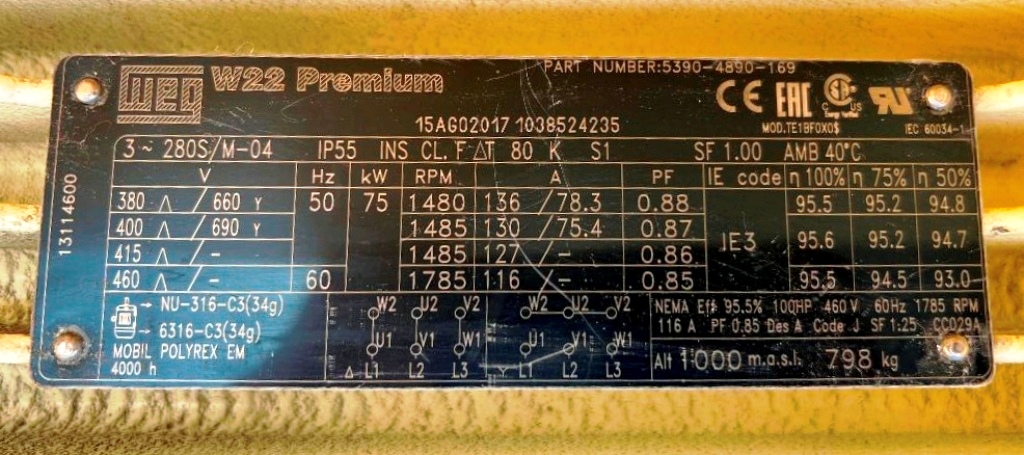

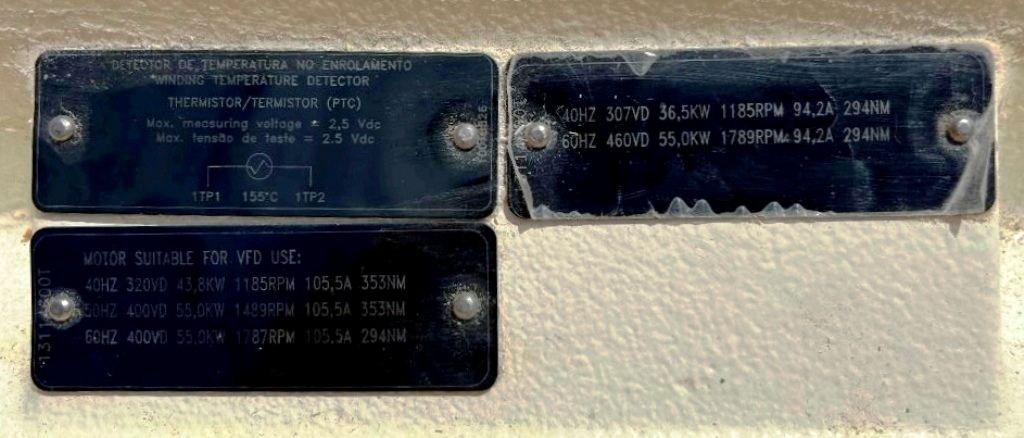

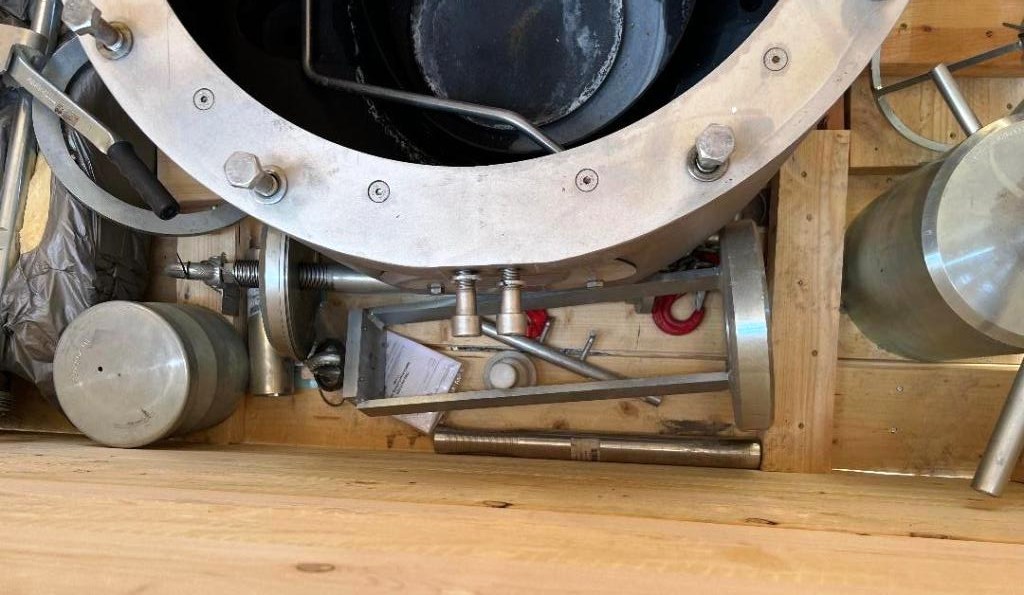

Max bowl speed 4800 RPM, rated @ 113,500 PPH/ 50,000 LPH, solids space 21 L, feed pressure 6 bar, skim milk and cream discharged under pressure via centripetal pumps, feed and discharge hydro-hermetically sealed. 75 KW motor 380/660/460/3/50/60/1480/1775 RPM, feed valve, constant pressure valve, flow meter, pressure gauge, water harness, tools, spares, manuals and PLC control panel with VFD. 2018 vintage. Used only 1 year. Excellent condition.

The Westfalia MSE 500-48-777 cold milk skimmer, 316SS. is engineered to deliver exceptional performance in the dairy processing industry. With a maximum bowl speed of 4800 RPM, this skimmer efficiently separates cream from skim milk, achieving a remarkable throughput capacity of 113,500 PPH or 50,000 LPH. The solids space of 21 liters allows for optimal processing of milk, ensuring that the separation process is both effective and efficient. The unit operates under a feed pressure of 6 bar, which is crucial for maintaining the necessary conditions for optimal separation. The discharge of skim milk and cream is facilitated by robust centripetal pumps, ensuring that the product is delivered under pressure, thus enhancing the overall efficiency of the operation. The hydro-hermetically sealed feed and discharge systems further contribute to the reliability and hygiene of the process, making this skimmer an ideal choice for modern dairy facilities.

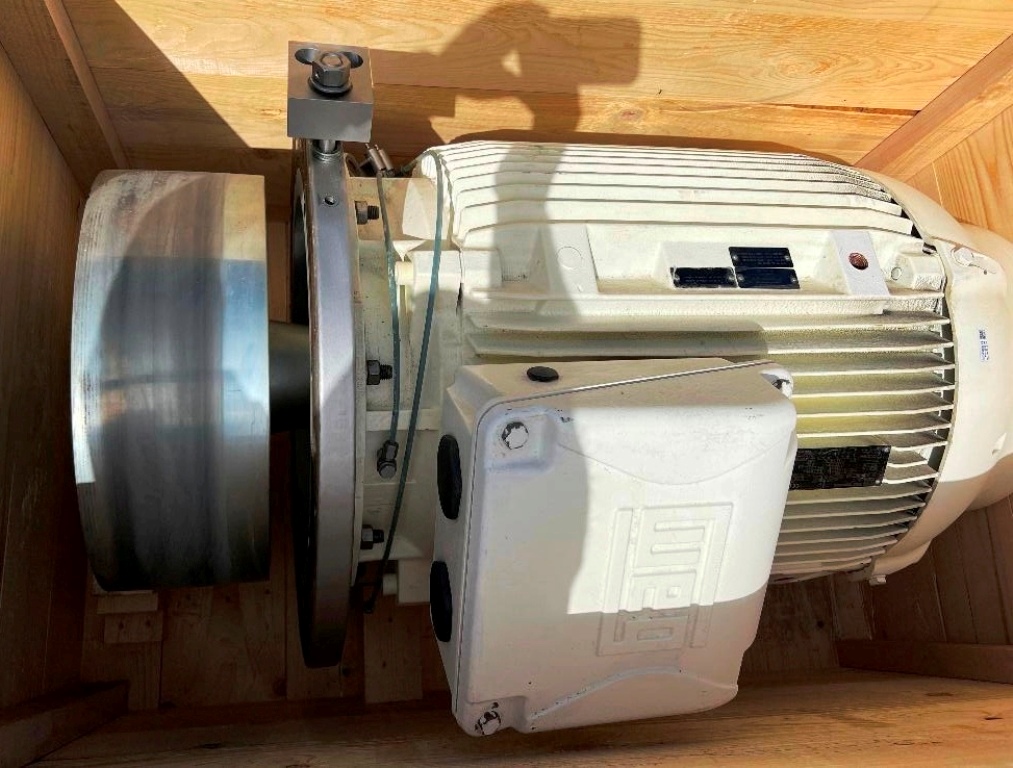

Equipped with a powerful 75 KW motor, the Westfalia MSE 500-48-777 operates at multiple voltage configurations (380/660/460/3/50/60/1480/1775 RPM), providing flexibility for various industrial settings. The inclusion of a feed valve, constant pressure valve, flow meter, and pressure gauge enhances the operational control, allowing for precise adjustments during the skimming process. Additionally, the unit comes with a comprehensive water harness, essential tools, spare parts, manuals, and a PLC control panel with Variable Frequency Drive (VFD), ensuring that operators can easily manage and maintain the equipment. This skimmer, manufactured in 2018 and used for only one year, is in excellent condition, making it a valuable asset for any dairy processing operation looking to enhance productivity and efficiency.

Key Features:

High-Speed Performance, Robust Construction, Comprehensive Control System, Efficient Separation Process, Excellent Condition