Description:

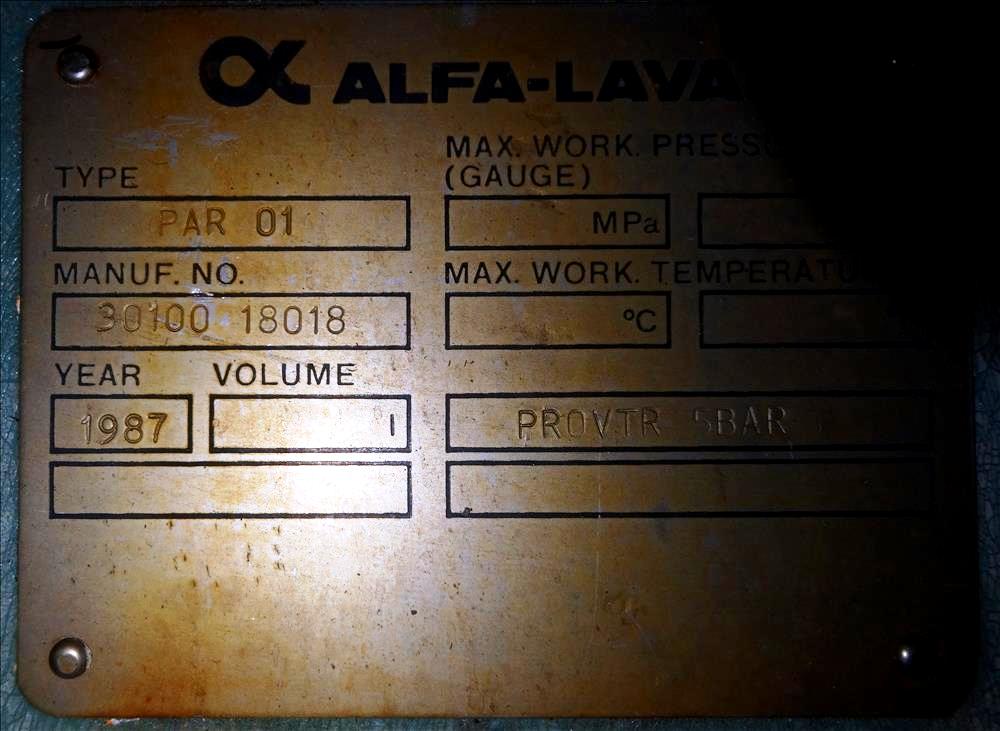

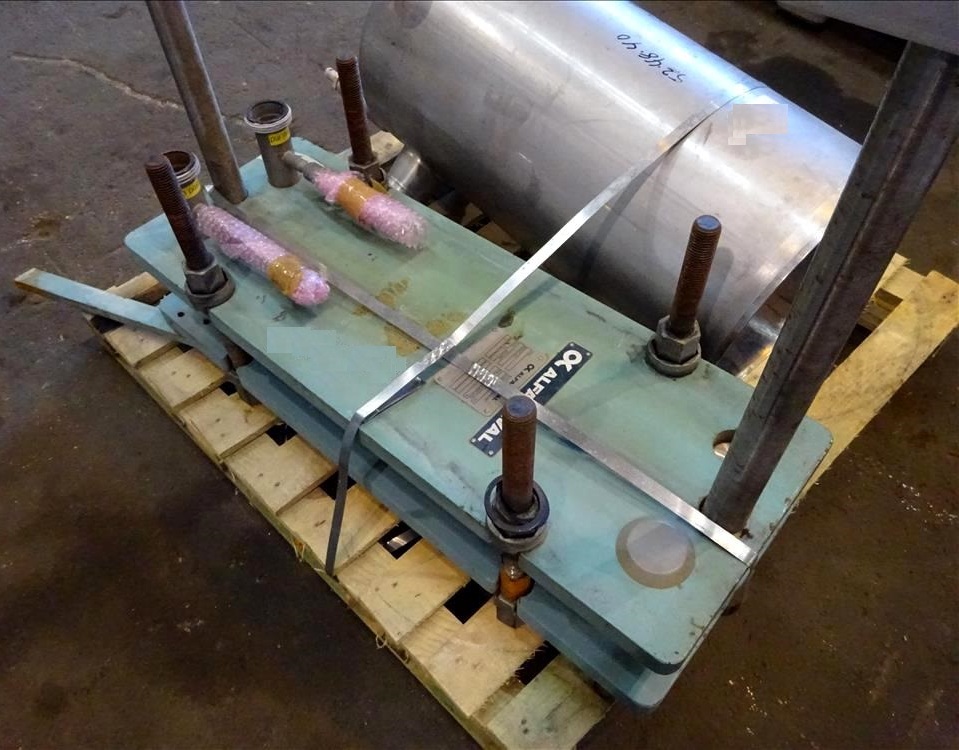

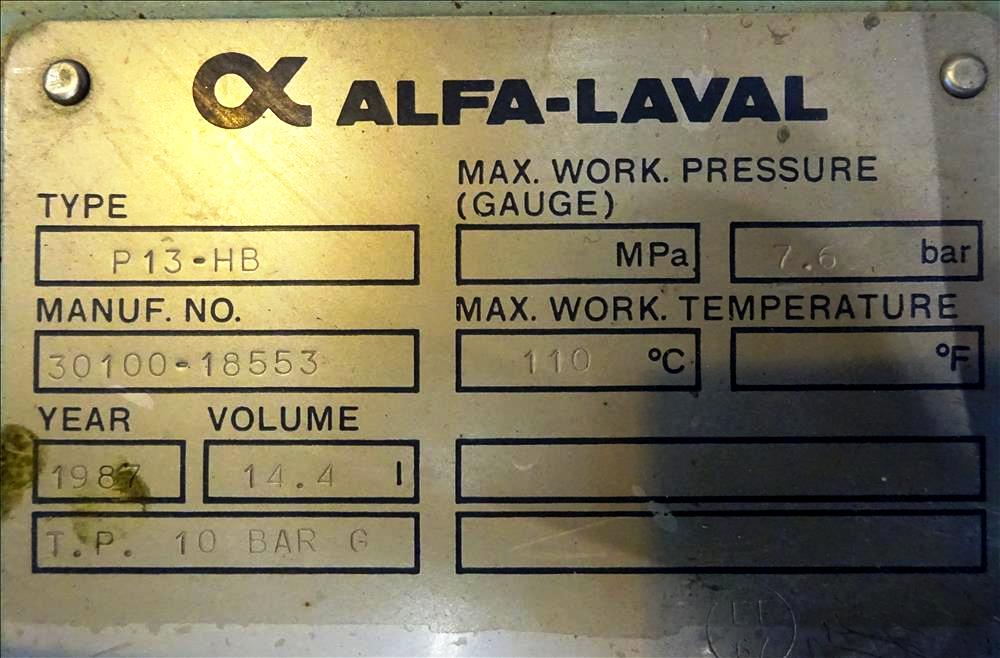

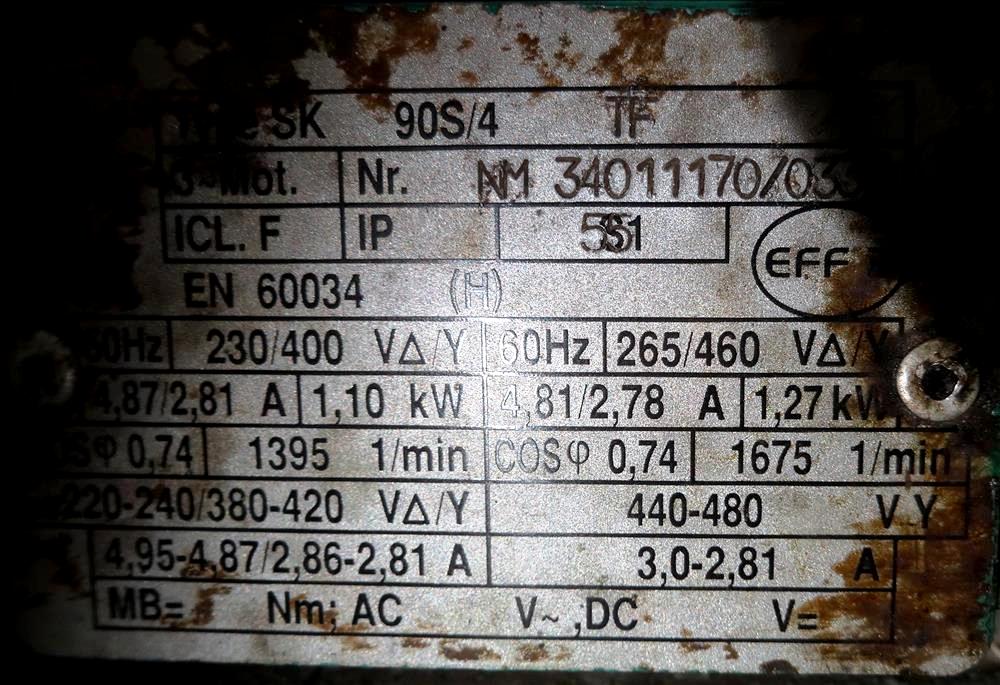

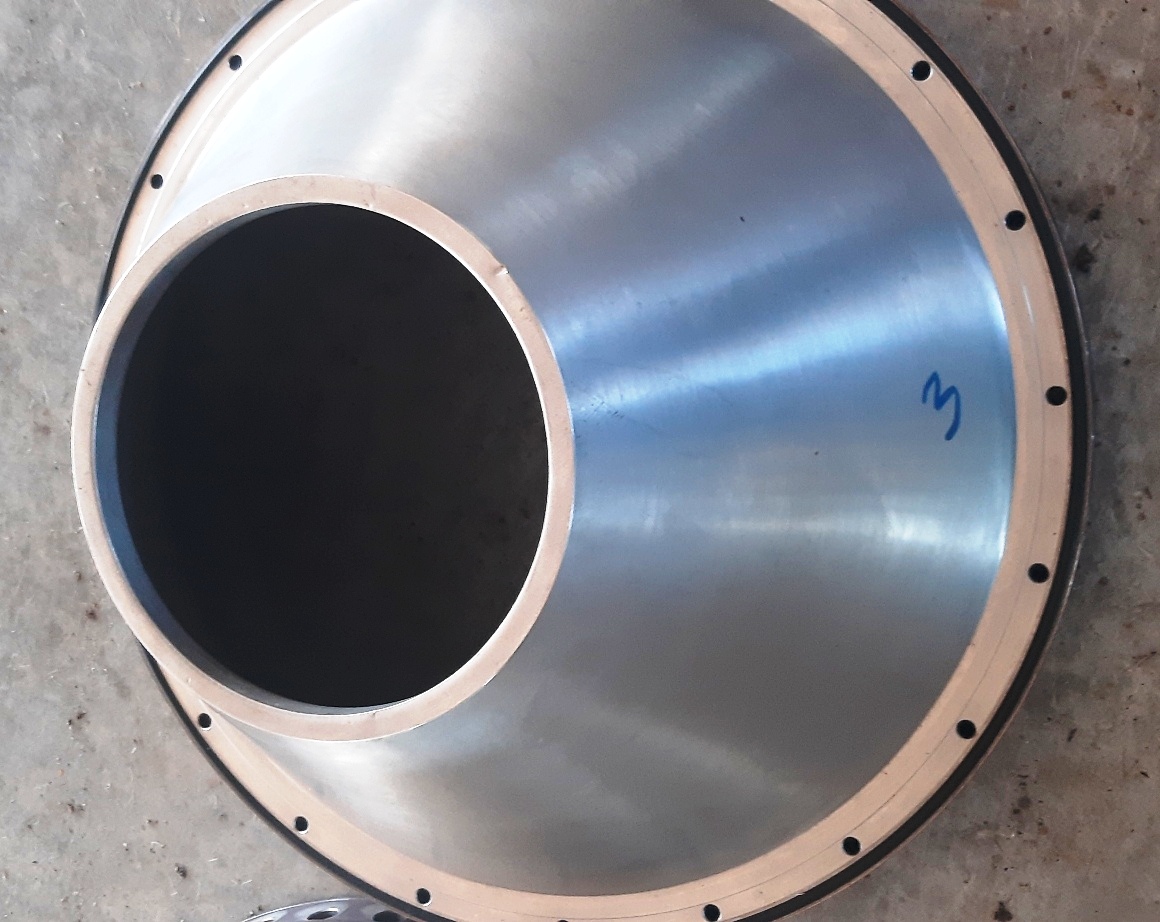

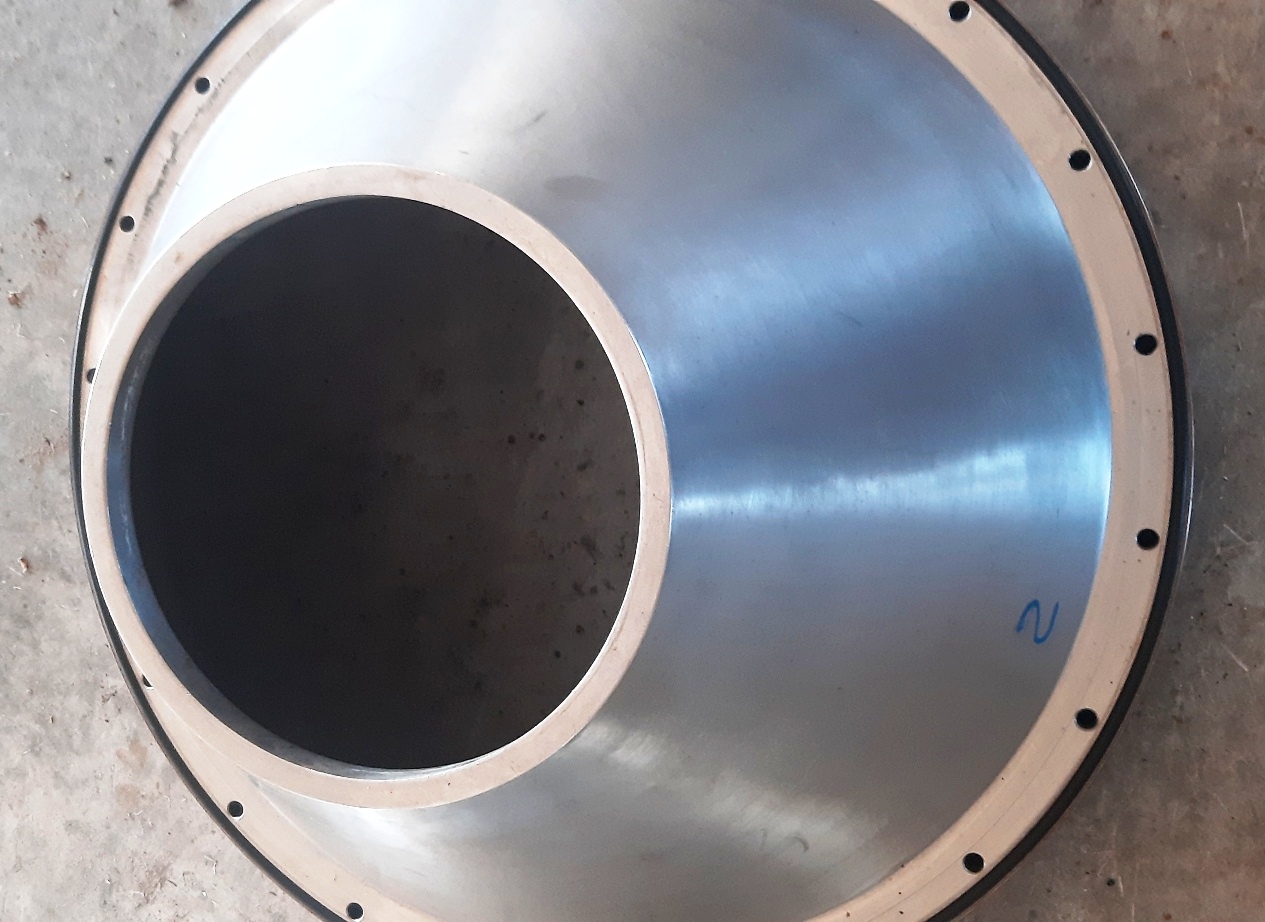

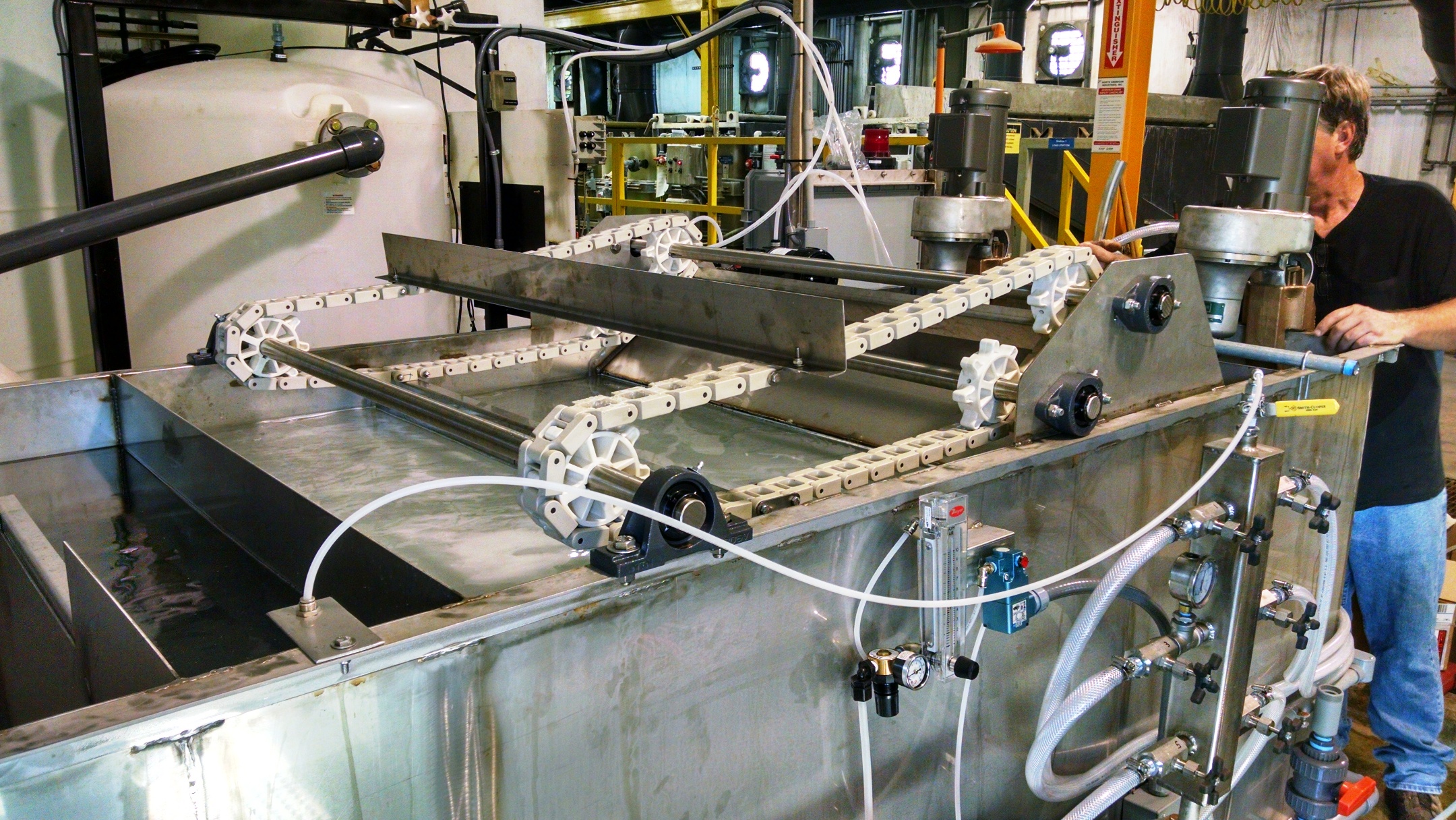

Thin-film, single-effect, spinning cone evaporator designed for highly viscous slurry to 20,000cP. Rated @ 800 LPH (12-65 Brix). Includes A/L P2-HL plate heat exchanger, A/L PAR22 PHE, (2) A/L PAR01 PHEs, A/L P13-HB PHE, Netzsch 1 KW cavity pump, 4 KW vacuum pump. Has Danfuss VLT drive and Danfuss VLT 6000 HVAC. 1987 vintage. Very good condition.

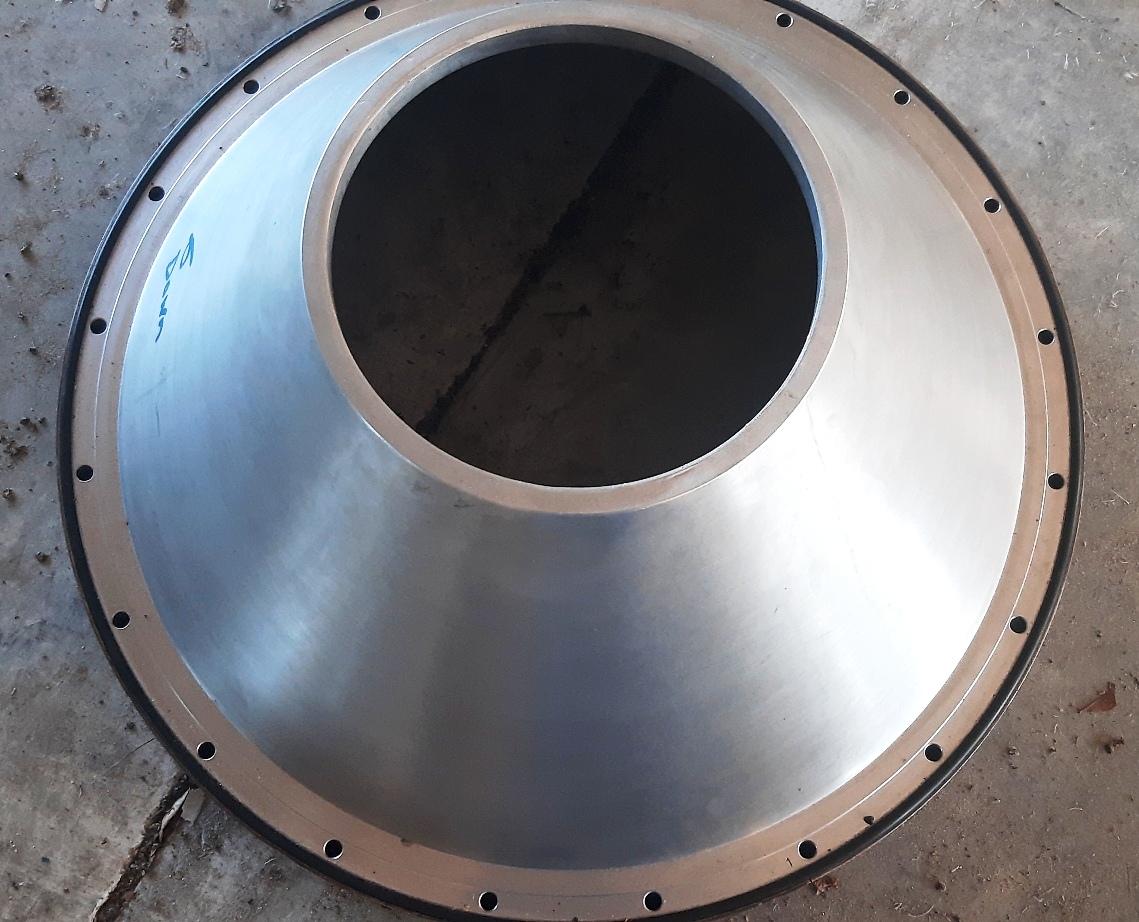

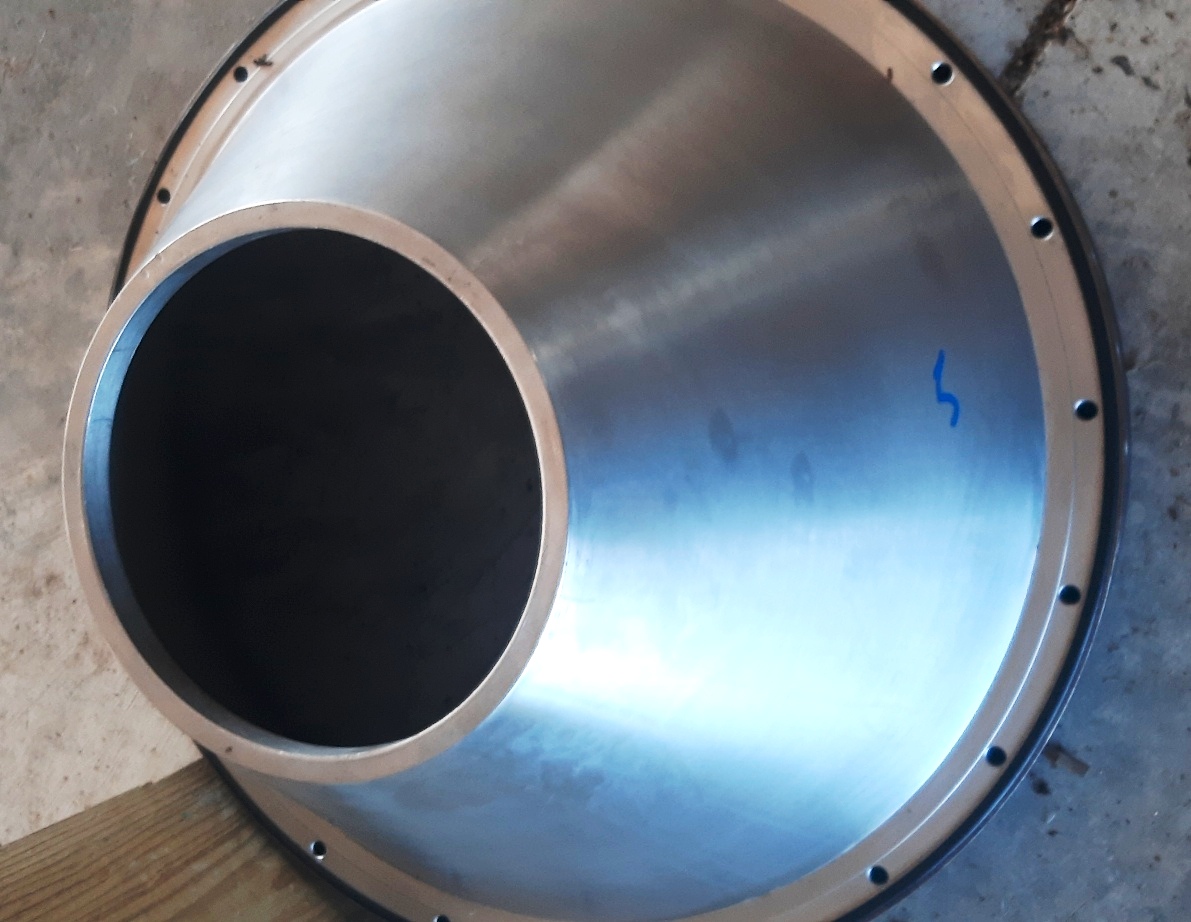

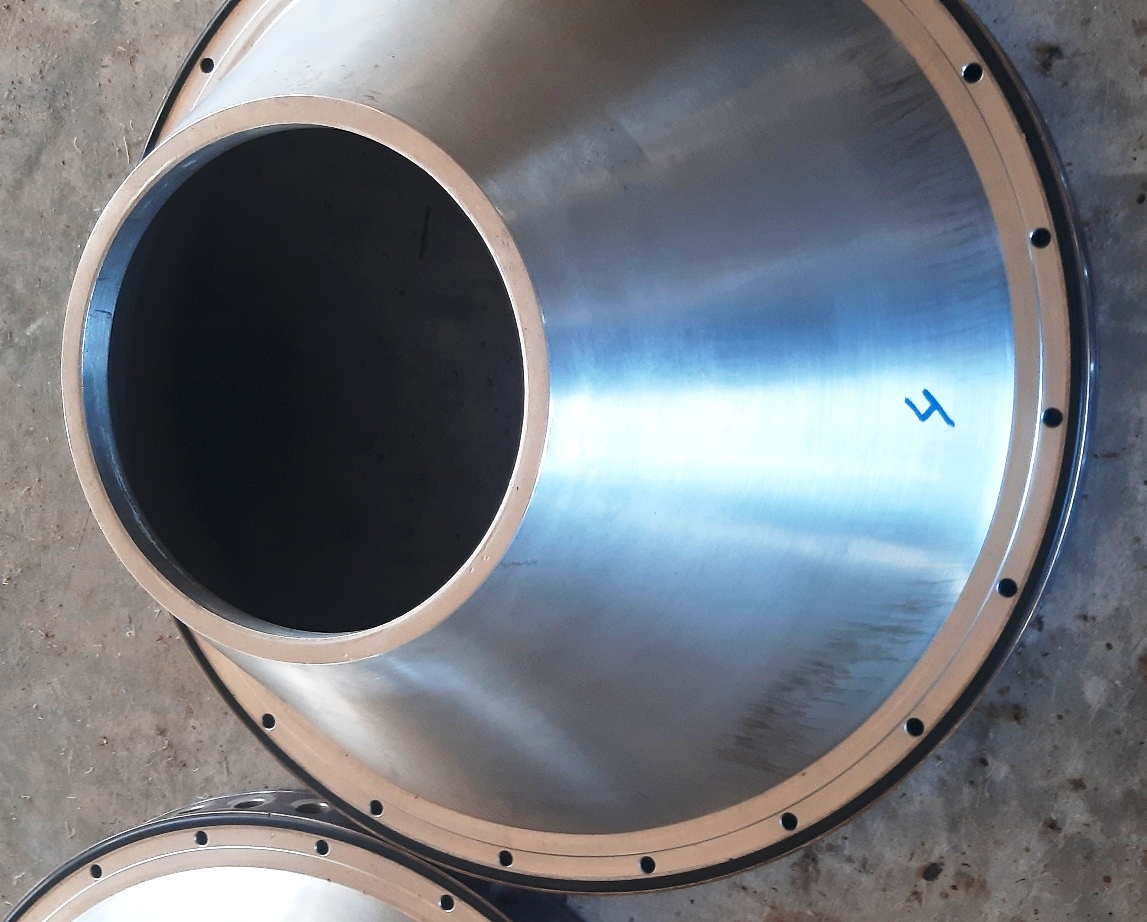

The Alfa-Laval CT-6 Centritherm evaporator, 316SS, is engineered to provide efficient and reliable processing of highly viscous slurries, making it an essential piece of equipment for industries such as food processing, pharmaceuticals, and chemical manufacturing. With a maximum viscosity of 20,000 cP, this thin-film evaporator excels in applications where traditional evaporators may struggle. Its single-effect design ensures optimal heat transfer and evaporation rates, allowing for a rated capacity of 800 liters per hour (LPH) at Brix levels ranging from 12 to 65. This versatility makes it suitable for a wide range of products, from concentrated juices to viscous pastes, thereby enhancing productivity and operational efficiency in your facility.

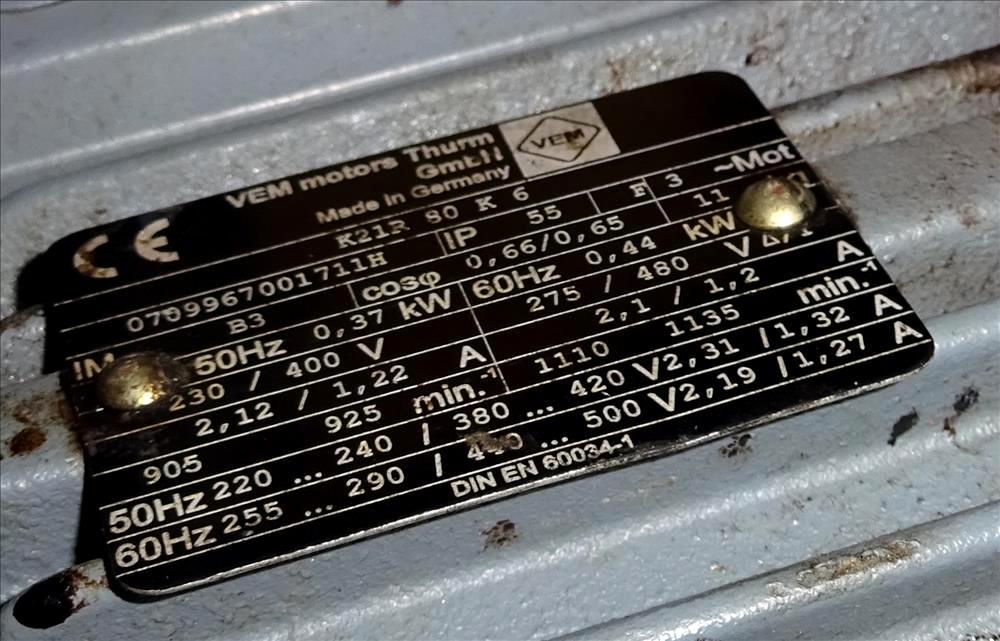

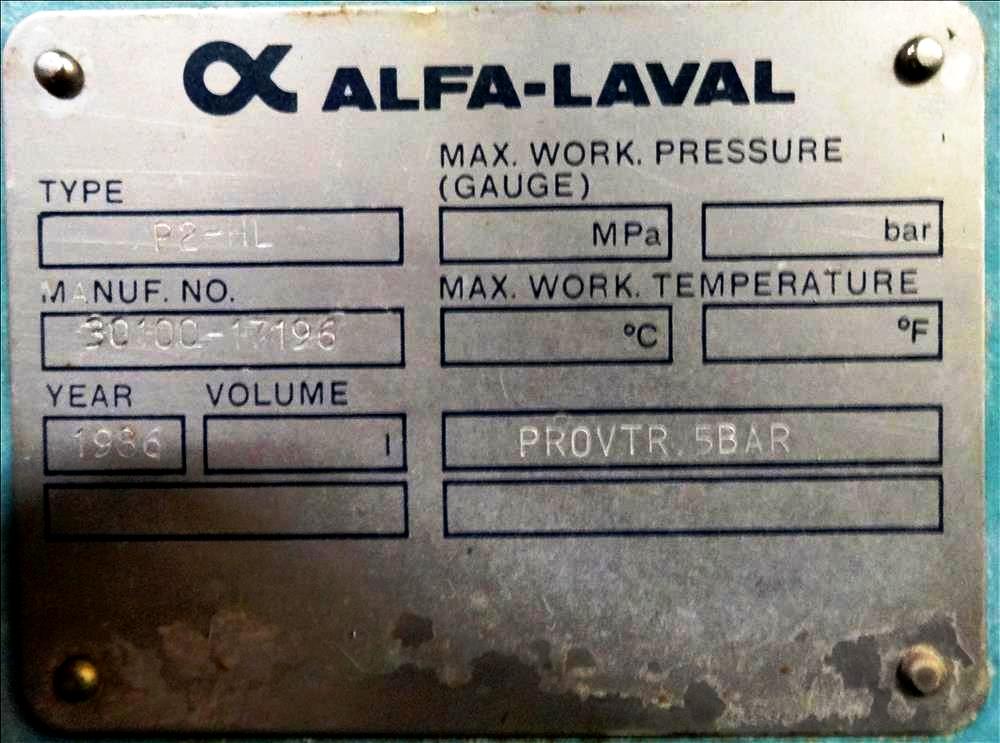

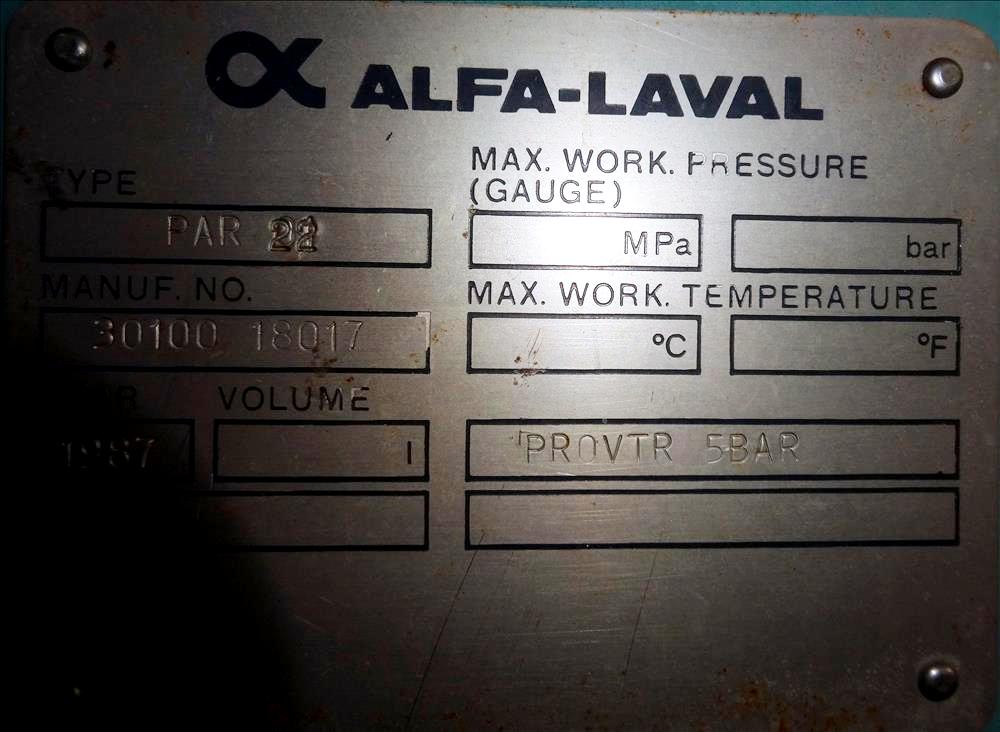

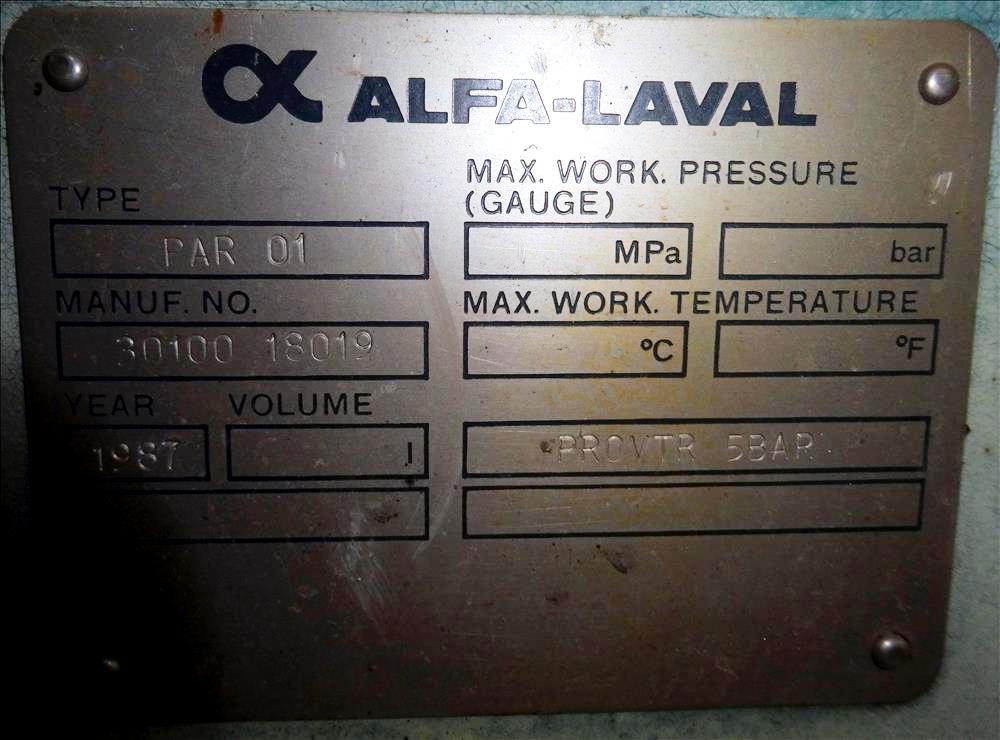

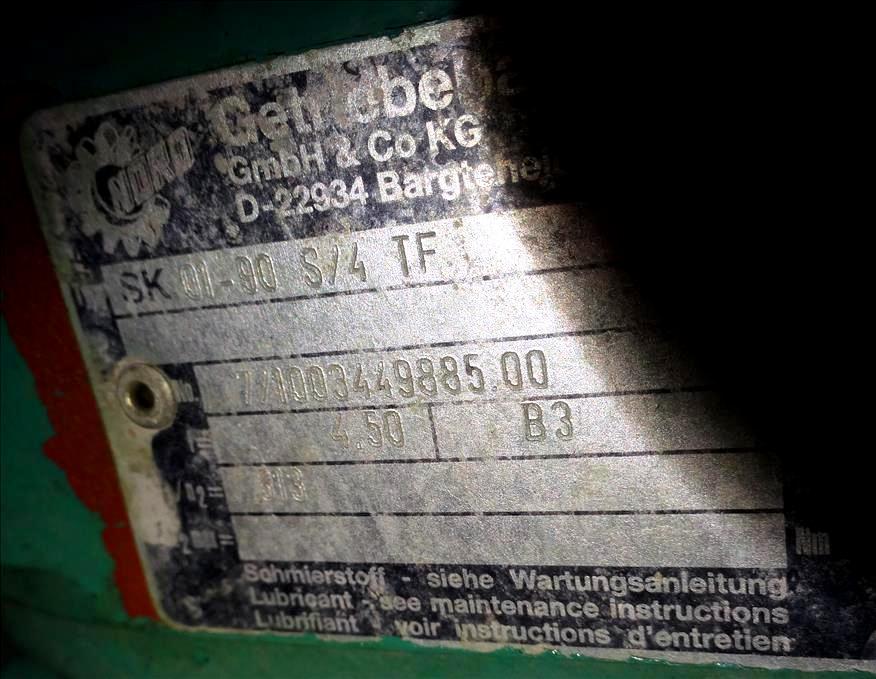

The Alfa-Laval CT-6 is equipped with a comprehensive suite of components that contribute to its superior performance. The inclusion of the A/L P2-HL plate heat exchanger and multiple A/L PAR plate heat exchangers ensures that the system maintains efficient thermal management throughout the evaporation process. Additionally, the Netzsch 1 KW cavity pump and 4 KW vacuum pump work in tandem to facilitate smooth material flow and maintain the necessary vacuum conditions for effective evaporation. The Danfoss VLT drive and Danfoss VLT 6000 HVAC system further enhance the operational capabilities of the evaporator, allowing for precise control over speed and temperature settings. With its 1987 vintage, this unit has been well-maintained and is in very good condition, making it a reliable choice for businesses looking to upgrade their processing capabilities without the need for a brand-new system.

Key Features:

High Viscosity Handling, Efficient Heat Transfer, Robust Pumping System, Precision Control, Excellent Condition