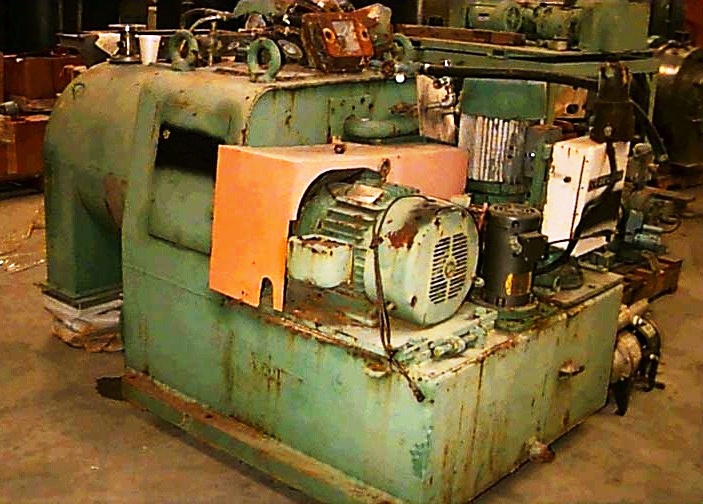

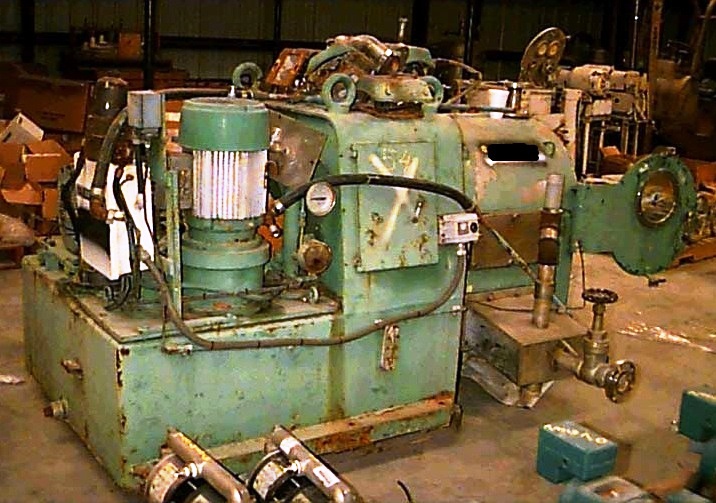

Description:

Max bowl speed 1600 RPM, 15 HP motor 230/460/3/60/1750, 10 hydraulic pusher motor, feed, wash and rinse pipes, unitized on inertia base with vibration isolators. Very good condition.

The Alfa-Laval SB-400 2 stage pusher centrifuge, 316SS. is engineered for high-efficiency separation processes, making it an ideal choice for various industrial applications. With a maximum bowl speed of 1600 RPM, this centrifuge is capable of achieving optimal separation of solids from liquids, ensuring high product quality and yield. The robust 15 HP motor, designed for 230/460V three-phase power supply, operates at 1750 RPM, providing the necessary torque and reliability for demanding separation tasks. The inclusion of a 10 hydraulic pusher motor enhances the operational efficiency, allowing for consistent and effective material handling throughout the centrifuge's processing cycle. The unitized design on an inertia base, combined with vibration isolators, minimizes operational noise and enhances stability, making it suitable for continuous operation in industrial environments.

Constructed from high-grade 316 stainless steel, the Alfa-Laval SB-400 is not only durable but also resistant to corrosion, ensuring longevity even when processing aggressive materials. The centrifuge is equipped with dedicated feed, wash, and rinse pipes, facilitating a streamlined workflow and reducing downtime during maintenance. This design feature allows for efficient cleaning and ensures that the machine can be quickly prepared for subsequent batches, enhancing productivity. The centrifuge's compact footprint and thoughtful engineering make it easy to integrate into existing production lines, providing flexibility for manufacturers looking to optimize their processes without extensive modifications to their facilities.

In addition to its impressive technical specifications, the Alfa-Laval SB-400 2 stage pusher centrifuge is known for its user-friendly operation and maintenance requirements. Operators will appreciate the straightforward controls and monitoring systems that allow for real-time adjustments and performance tracking. Regular maintenance is simplified by the centrifuge's design, which allows for easy access to critical components. This ensures that the machine remains in peak operating condition, minimizing the risk of unexpected downtime and maximizing overall efficiency in production.

Key Features:

High-Speed Performance, Durable Construction, Efficient Material Handling, User-Friendly Operation, Easy Maintenance