Description:

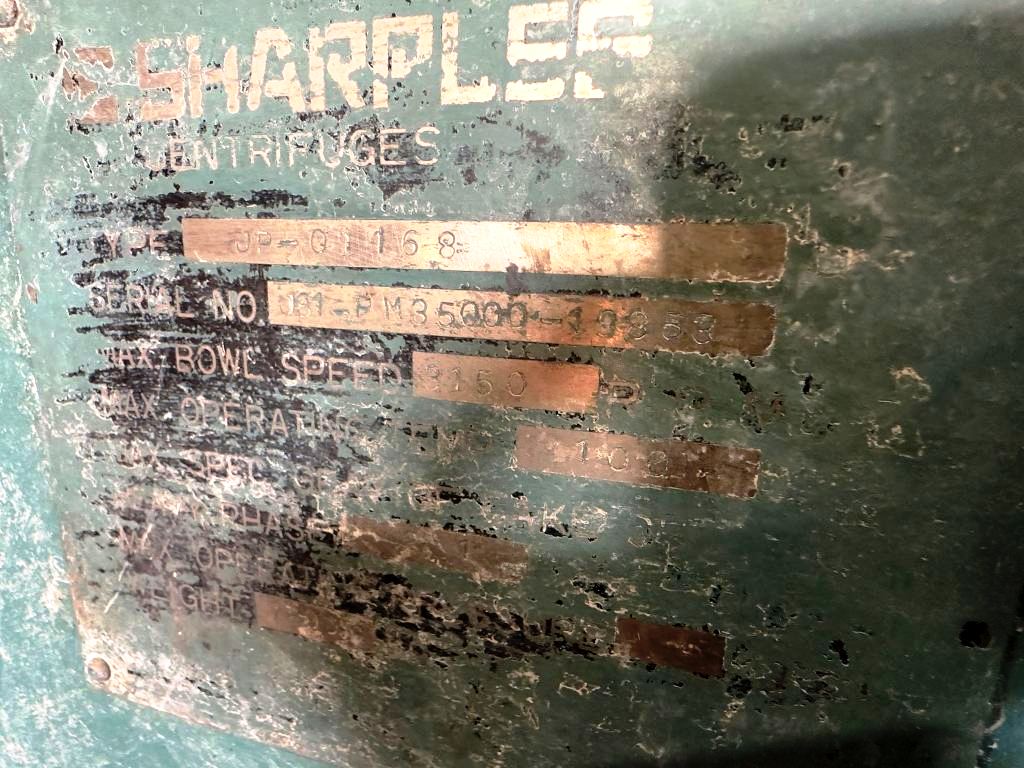

Max bowl speed 3150 RPM, 2360 x G, 360 degree cake discharge with carbide wear liners, moon liquid plate dams, 5.5" single lead STC-tiled conveyor, 30 HP motor 380/3/60/1450 RPM, 52:1 gearbox, 10 HP backdrive, guards and feed tube, mounted on a stand with control panel with VFDs. 1981 vintage. Very good condition. Located in Australia.

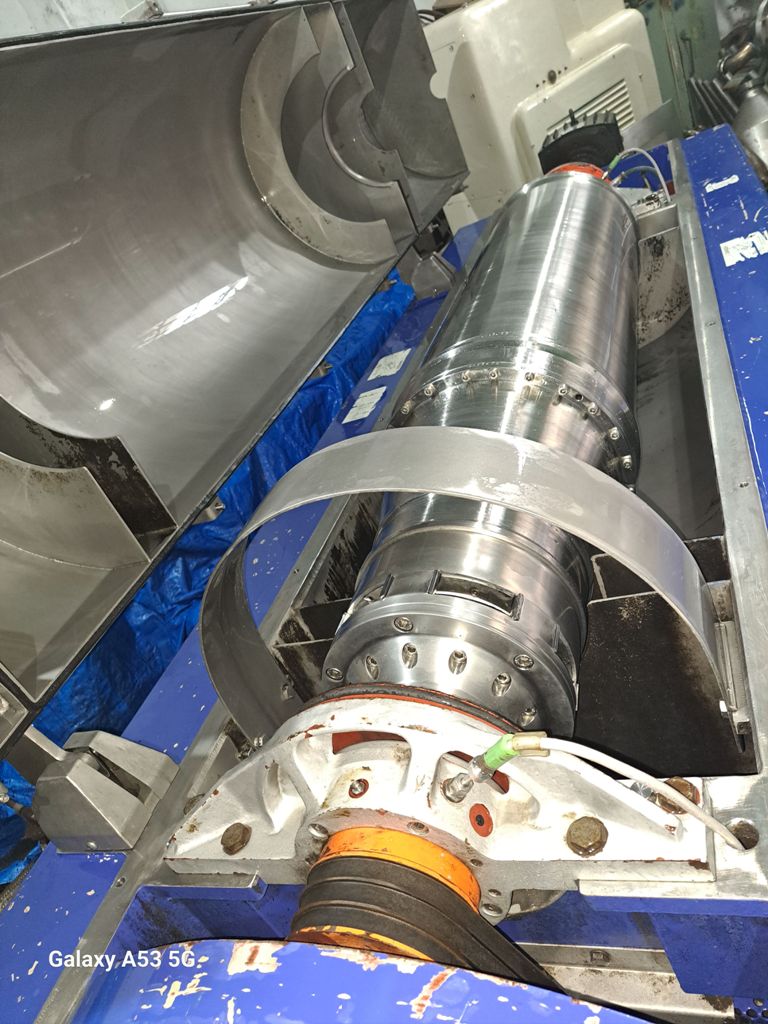

The Sharples PM-35,000 Super-D-Canter centrifuge, 316SS. is engineered for high-performance separation processes, making it an essential asset in various industrial applications. With a maximum bowl speed of 3150 RPM and a centrifugal force of 2360 x G, this centrifuge is designed to efficiently separate solids from liquids, ensuring optimal product purity and yield. The unique 360-degree cake discharge system, equipped with carbide wear liners, enhances the durability and longevity of the machine while facilitating easy and complete discharge of the separated solids. Additionally, the innovative moon liquid plate dams help in maintaining the integrity of the liquid phase during operation, thus maximizing separation efficiency and minimizing product loss.

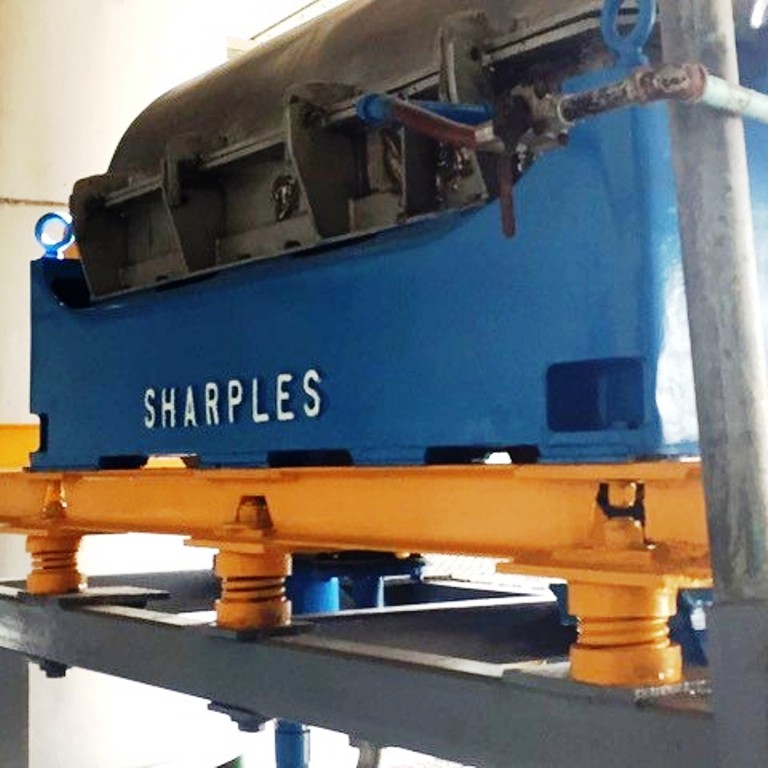

The centrifuge is powered by a robust 30 HP motor, operating at 380/3/60/1450 RPM, which is complemented by a 52:1 gearbox for optimal torque and speed control. The inclusion of a 10 HP backdrive ensures that the system can handle varying load conditions effectively, providing consistent performance across different operational scenarios. Safety and ease of operation are paramount, which is why the Sharples PM-35,000 is equipped with guards and a feed tube, all mounted on a sturdy stand that includes a control panel with variable frequency drives (VFDs). This setup allows for precise control over the centrifuge's operation, making it adaptable to a wide range of processing needs. With its vintage from 1981 and its very good condition, this centrifuge represents a reliable investment for businesses looking to enhance their separation capabilities.

Located in Australia, the Sharples PM-35,000 Super-D-Canter centrifuge, 316SS. is not only a testament to engineering excellence but also a practical solution for industries such as food processing, pharmaceuticals, and wastewater treatment. Its stainless steel construction ensures resistance to corrosion and wear, making it suitable for handling a variety of materials. Whether you are looking to upgrade your existing equipment or expand your processing capabilities, this centrifuge offers a blend of performance, reliability, and efficiency that can significantly improve your operational outcomes.

Key Features:

High-Speed Performance, Durable Construction, Easy Maintenance, Versatile Applications, Advanced Control System