Description:

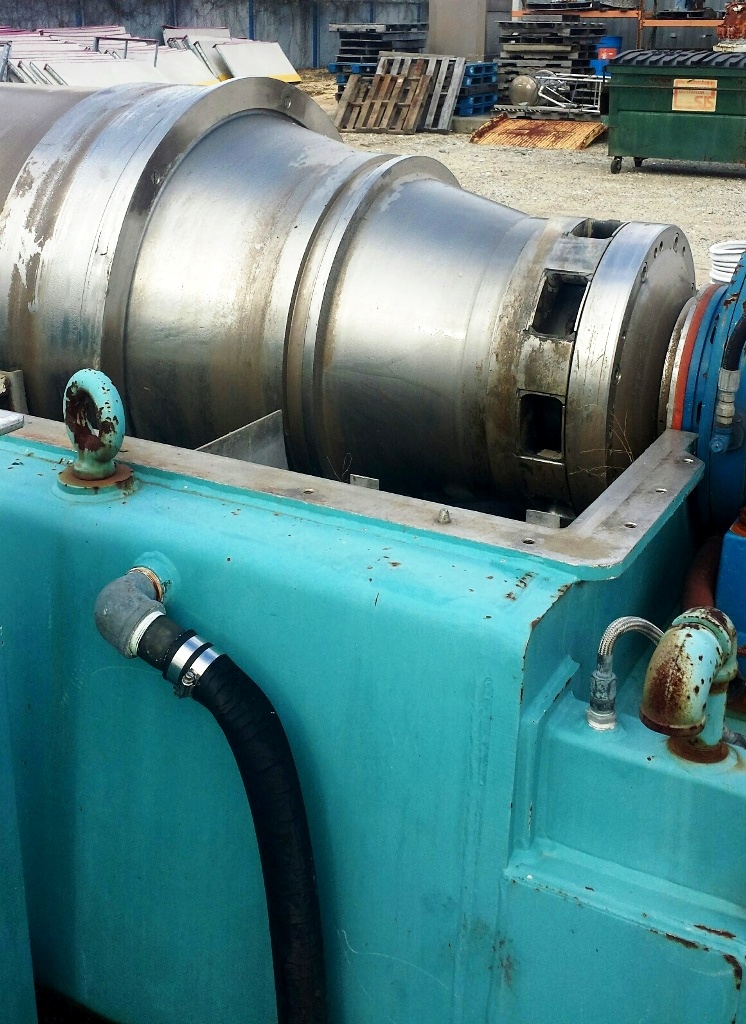

Max bowl speed 2600 RPM, 2780 G's, 15 degree beach, 360 degree cake discharge, 10" single lead conveyor with STC tiles & STC feed zone, BD disc, moon liquid plate dams, SS casings and chutes, feed tube, 95:1 gearbox, lube system, 300 HP motor 460/3/60/1780 RPM, 60 HP DC backdrive and stand, vibration switch, guards, bowl dolly and control panel. 1987 vintage. Prior use: Thickening WAS. Very good condition.

The Sharples XM-706 Super-D-Canter centrifuge, 316SS, is engineered for high-efficiency separation processes, making it an ideal choice for industries requiring robust thickening capabilities. With a maximum bowl speed of 2600 RPM and the ability to generate 2780 G's, this centrifuge excels in effectively separating solids from liquids. The 15-degree beach angle enhances the sedimentation process, ensuring optimal cake formation and discharge. The 360-degree cake discharge feature allows for efficient removal of the separated solids, minimizing downtime and maximizing productivity. The 10-inch single lead conveyor, equipped with STC tiles and an STC feed zone, ensures smooth and reliable material handling, while the BD disc and moon liquid plate dams contribute to effective liquid separation, enhancing the overall performance of the unit.

Constructed with 316 stainless steel, the Sharples XM-706 Super-D-Canter is designed for durability and resistance to corrosion, making it suitable for a variety of industrial applications. The inclusion of a 95:1 gearbox and a powerful 300 HP motor, operating at 460/3/60/1780 RPM, provides the necessary torque and speed for efficient operation. Additionally, the 60 HP DC backdrive and stand facilitate smooth operation and control, while the integrated lubrication system ensures optimal performance and longevity of the mechanical components. Safety features such as a vibration switch and protective guards enhance operational safety, while the included bowl dolly and control panel allow for easy maneuverability and user-friendly operation. This 1987 vintage unit, previously used for thickening waste activated sludge (WAS), is in very good condition, making it a reliable option for businesses looking to enhance their separation processes.

Key Features:

High-Speed Performance, Durable Construction, Efficient Cake Discharge, User-Friendly Operation, Safety Features