Description:

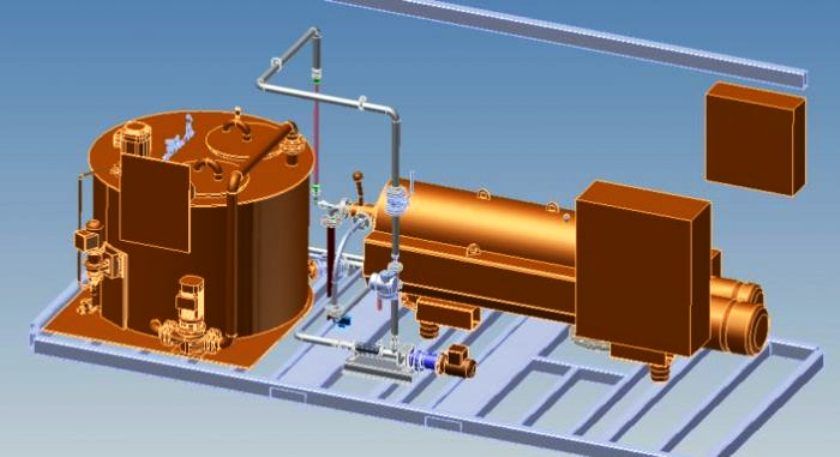

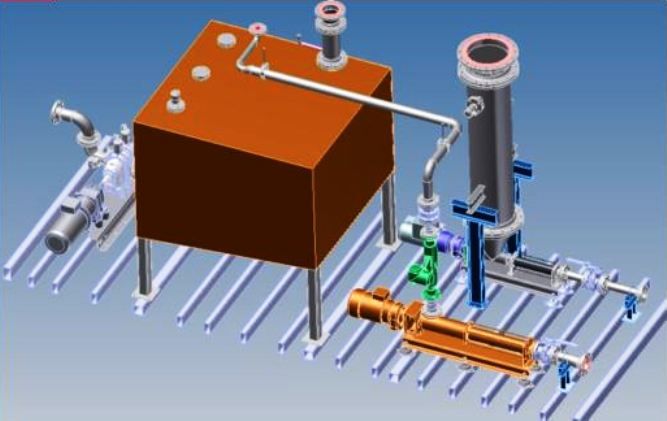

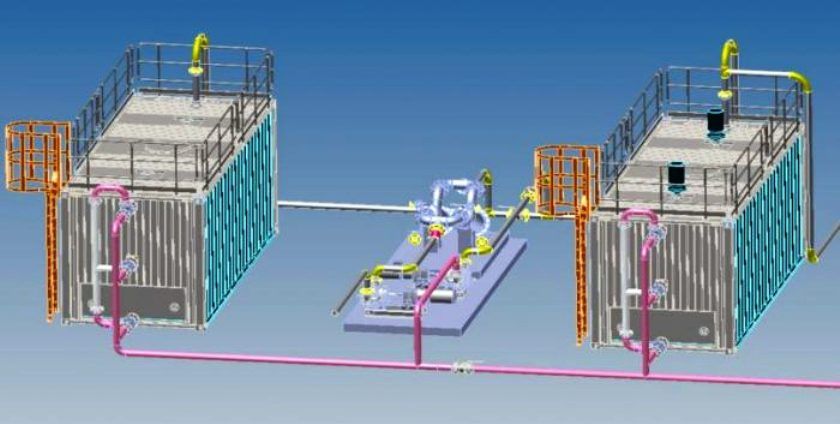

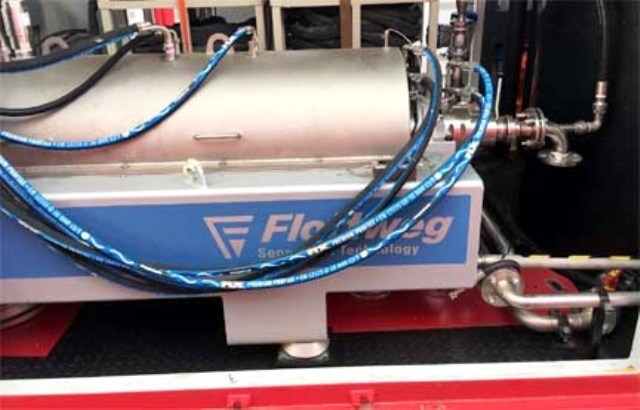

This compact/portable tricanter system is designed for up to 95% product recovery ready to be re-injected back into the refining stream line. The 3-phase separation system consists of 5 containers. Zone 1 is explosion-proof. Two UNUSED Flottweg Z4E-4/441G gastite tricanters. Power supply and control panels. First stage pre-treatment tank with heating coils. 2nd stage pre-treatment tank w/heating coils & mixers. Two 7.5 KW suction transfer pumps. Pre-filter unit. Piping system and all connecting elements. Never used!

The Waste Oil Recovery & Sludge Treatment Plant is engineered to maximize efficiency in the recovery of valuable oil products from waste streams. This advanced tricanter system is not only compact and portable but also boasts a remarkable capability of achieving up to 95% product recovery. This high level of efficiency ensures that recovered oil can be seamlessly re-injected back into the refining stream line, significantly reducing waste and enhancing overall operational sustainability. The system is designed with a robust 3-phase separation mechanism that effectively segregates oil, water, and solids, ensuring that each component is processed optimally. The inclusion of five strategically designed containers facilitates this separation process, with Zone 1 being explosion-proof to ensure safety in hazardous environments, making it suitable for various industrial applications where flammable materials may be present.

The Waste Oil Recovery & Sludge Treatment Plant is equipped with two UNUSED Flottweg Z4E-4/441G gastite tricanters, which are known for their reliability and high performance. These tricanters are complemented by a comprehensive power supply and control panel setup, allowing for easy operation and monitoring of the system. The first stage pre-treatment tank is fitted with heating coils, which are essential for maintaining the optimal temperature required for effective oil recovery. Additionally, the second stage pre-treatment tank includes both heating coils and mixers, ensuring thorough mixing and preparation of the waste oil before it undergoes separation. The system is also outfitted with two 7.5 KW suction transfer pumps and a pre-filter unit, which work in tandem to enhance the efficiency of the entire process. The well-designed piping system and all necessary connecting elements ensure that the Waste Oil Recovery & Sludge Treatment Plant operates smoothly and effectively, making it an invaluable asset for industries looking to improve their waste management practices.

Key Features:

High Recovery Efficiency, Explosion-Proof Design, Advanced Pre-Treatment, Reliable Tricanter Technology, Comprehensive System Components

Frequently Asked Questions

We're sorry, but this item has been sold.

Please consider the alternatives below.