Description:

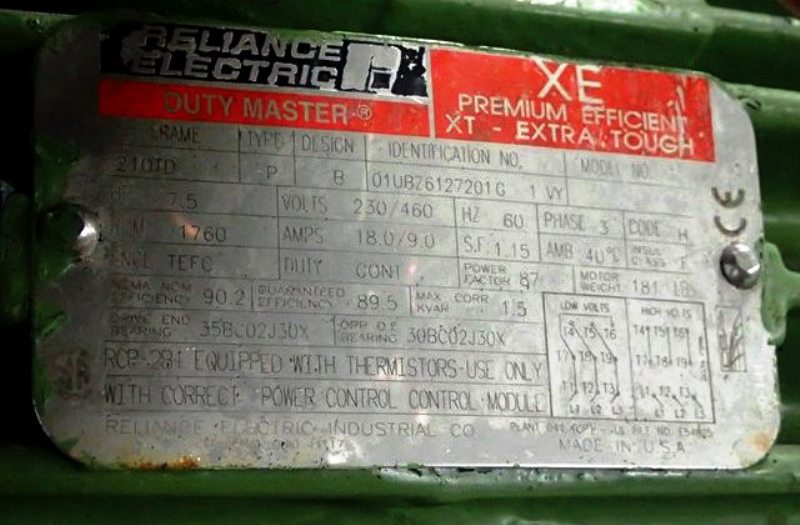

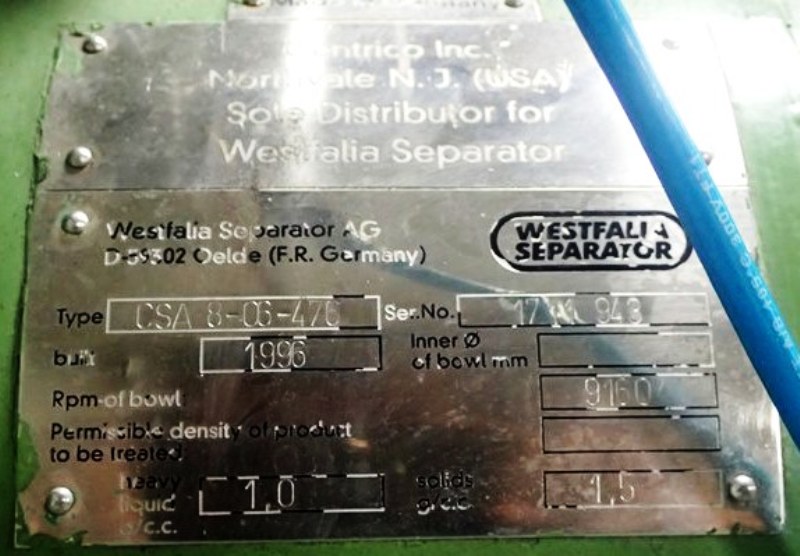

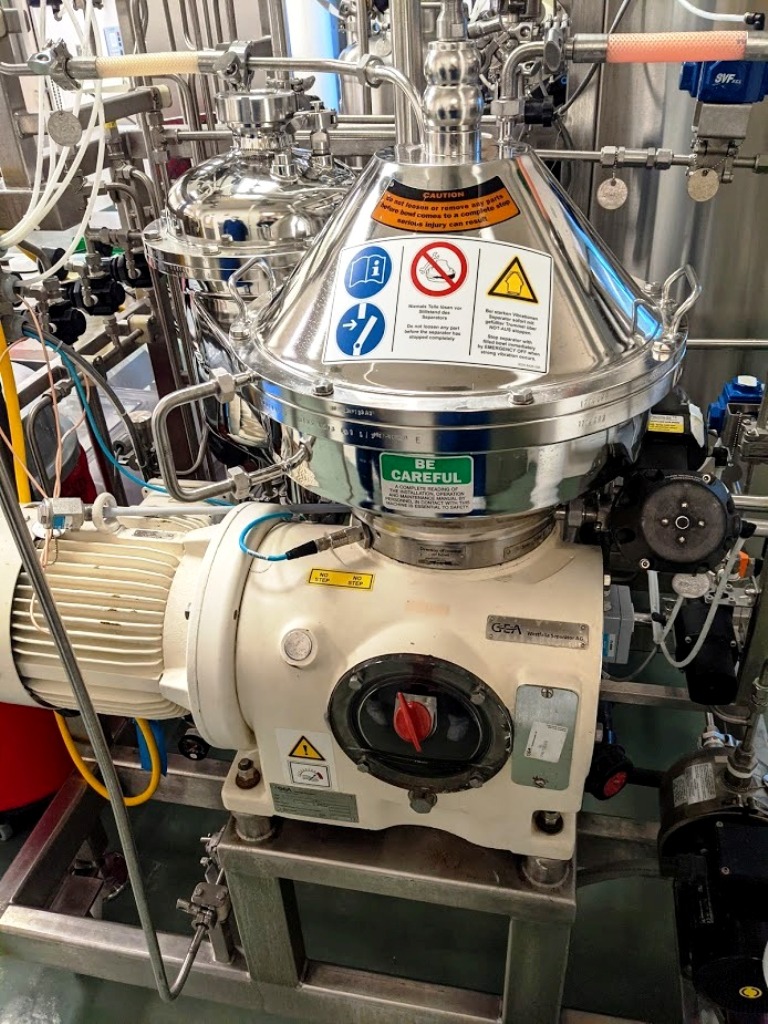

Max bowl speed 9160 RPM, CIP/SIP (sterilizable), rated @ 100 LPH, 1.5 L sludge cap, max pressure 1.5 bar @ 127C, automatic photoelectric liquid sensors (turbidity meter), 7.5 HP motor 230/460/3/60/1750 RPM, sludge tank, peristaltic pump and control panel. Unitized on skid. No tools. Prior use: Biotech. 1996 vintage. Excellent condition.

The Westfalia CSA 8-06-476 biotech clarifier, 316SS. is engineered for high-performance separation in biotechnology applications. With a maximum bowl speed of 9160 RPM, this clarifier efficiently processes liquids to achieve optimal clarity and purity. The unit is rated for a throughput of 100 liters per hour, making it suitable for various biotech processes that require precise liquid clarification. Its robust construction from 316 stainless steel ensures durability and resistance to corrosion, which is essential for maintaining hygiene and integrity in sensitive environments. The integrated automatic photoelectric liquid sensors, or turbidity meters, provide real-time monitoring of liquid clarity, allowing for immediate adjustments to maintain product quality throughout the operation cycle. This feature is particularly beneficial in biotech applications where even minor variations in liquid clarity can impact downstream processes.

Designed with user convenience in mind, the Westfalia CSA 8-06-476 is equipped with a clean-in-place (CIP) and sterilize-in-place (SIP) capability, which simplifies maintenance and ensures that the equipment can be thoroughly cleaned without disassembly. This is crucial in biotech settings where contamination must be avoided at all costs. The unit's sludge tank and peristaltic pump work in tandem to manage waste efficiently, while the control panel provides intuitive operation and monitoring capabilities. The system operates under a maximum pressure of 1.5 bar at a temperature of 127 degrees Celsius, making it suitable for a variety of processing conditions. The entire assembly is unitized on a skid, allowing for easy installation and relocation without the need for specialized tools. This feature not only saves time during setup but also enhances the flexibility of the equipment in dynamic production environments.

Key Features:

High-Speed Performance, Durable Construction, Easy Maintenance, Real-Time Monitoring, Flexible Installation