Description:

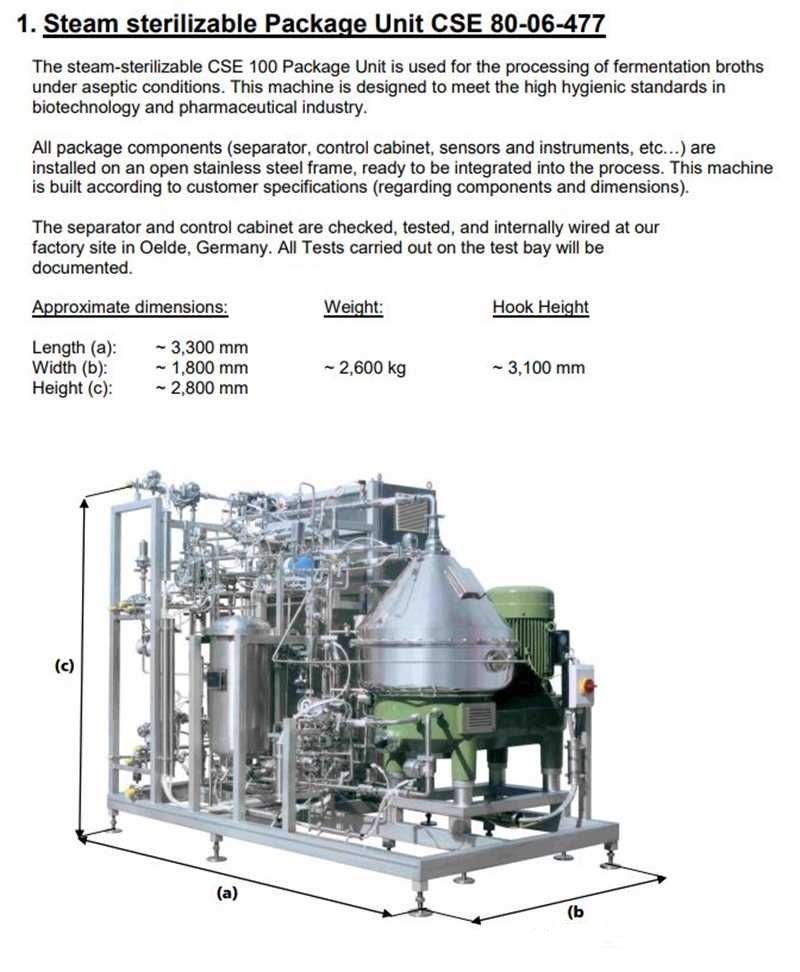

Max bowl speed 7250 RPM, 13,100 x G, rated @ 1200-2300 LPH, solids capacity 10 L, bowl volume 20 L. Steam sterilizable (SIP up to 2.5 bar @ 137C) FDA/USP class 4 seals, fully CIP, hydrohermetic feed system, 18.5 KW motor 380/3/50/1450 RPM with VFD, solids cyclone with illuminated sight glass and static spray ball, feed pump, all valves and piping, vibration monitor, tools and PLC control panels unitized on a portable skid. Designed for: Veterinary vaccines. 2019 vintage. Never used; still in crates. Located in Europe.

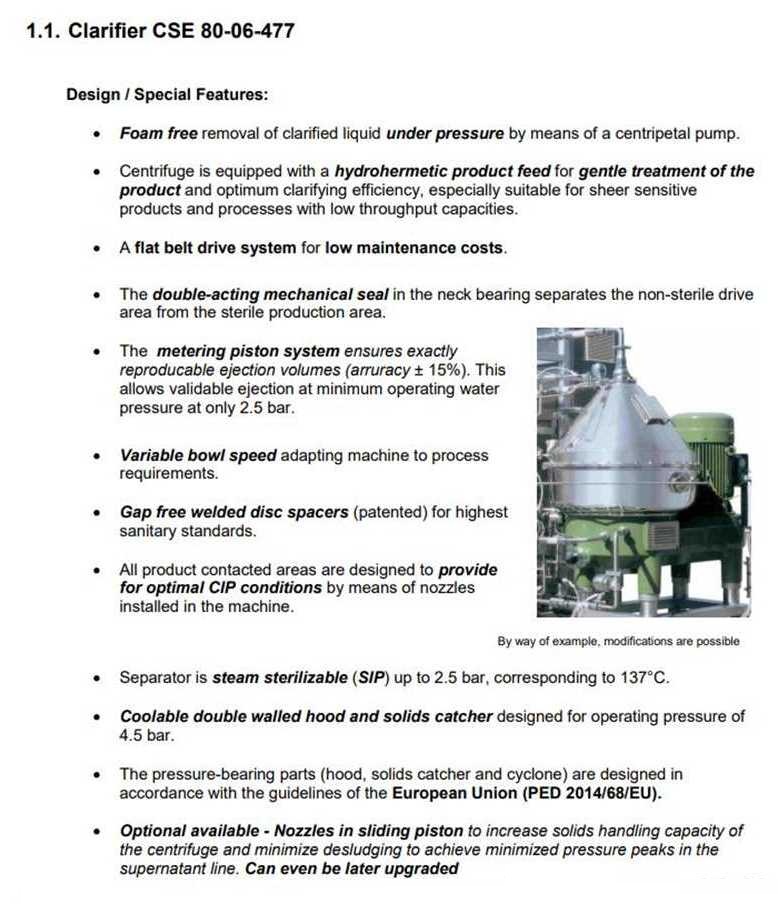

The Westfalia CSE 80-06-477 biotech clarifier module is engineered to meet the rigorous demands of the biotechnology and pharmaceutical industries, particularly in the production of veterinary vaccines. With a maximum bowl speed of 7250 RPM and a centrifugal force of 13,100 x G, this clarifier is capable of efficiently separating solids from liquids, ensuring high purity and quality in the final product. The system is rated for a throughput of 1200-2300 liters per hour, making it suitable for both small-scale and larger production runs. The robust solids capacity of 10 liters and a bowl volume of 20 liters allows for effective processing of various feed materials, accommodating a range of operational needs in the biotech sector.

Designed with user safety and operational efficiency in mind, the Westfalia CSE 80-06-477 features steam-in-place (SIP) capabilities, allowing for sterilization at pressures up to 2.5 bar and temperatures of 137°C. This ensures that the equipment meets stringent hygiene standards, crucial for the production of veterinary vaccines. The FDA/USP class 4 seals and fully clean-in-place (CIP) functionality further enhance the module's reliability and compliance with industry regulations. Additionally, the hydrohermetic feed system minimizes the risk of contamination, while the integrated solids cyclone, illuminated sight glass, and static spray ball facilitate easy monitoring and maintenance. The unit is powered by an 18.5 KW motor with variable frequency drive (VFD), providing precise control over the operational parameters, which is essential for optimizing performance and energy efficiency.

Key Features:

High-Speed Performance, Durable Construction, Steam Sterilizable, Efficient Cleaning System, Integrated Monitoring Features