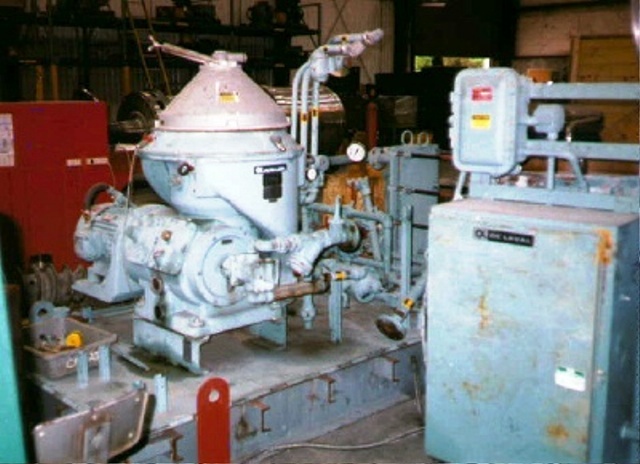

Description:

Max bowl speed 5100 RPM, rated @ 36 GPM on glycerin, both liquid phases discharged under pressure, nickel plated wetted parts. 15 HP XP motor 440/3/60/1800 RPM with VFD, feed pump, strainer, sight glasses, thermometer, seal water connections w/flow indicator, revolution counter, feed shut-off valve, water harness, tools, Alfa-Laval P2 (50 SS) plate and frame heat exchanger and PLC control panel. Unitized on a stand with oil tank. Reconditioned by OEM and test run only.

The Alfa-Laval MAPX 210 TGT-29-60 biodiesel module, SS. is engineered to provide exceptional performance in biodiesel production, particularly in the separation of glycerin and other liquid phases. With a maximum bowl speed of 5100 RPM, this module is capable of processing up to 36 gallons per minute (GPM) of glycerin, ensuring efficient and rapid separation. The design incorporates nickel-plated wetted parts, which not only enhance durability but also resist corrosion, making it suitable for handling various biodiesel feedstocks. The unit's ability to discharge both liquid phases under pressure further optimizes the separation process, allowing for a streamlined operation that minimizes downtime and maximizes output quality.

Equipped with a robust 15 HP XP motor operating at 440 volts, 3-phase, and 60 Hz, the Alfa-Laval MAPX 210 TGT-29-60 biodiesel module, SS. features a variable frequency drive (VFD) that allows for precise control over the motor speed. This adaptability is crucial in meeting varying production demands while maintaining energy efficiency. Additionally, the module comes with a comprehensive suite of components, including a feed pump, strainer, sight glasses, thermometer, and seal water connections with a flow indicator. The inclusion of a PLC control panel facilitates easy monitoring and automation of the biodiesel production process, ensuring that operators can maintain optimal performance with minimal manual intervention. The unit is mounted on a sturdy stand with an integrated oil tank, providing a compact and organized solution for biodiesel processing.

Reconditioned by the original equipment manufacturer (OEM) and test run only, this biodiesel module promises reliability and performance akin to new equipment. It is an excellent choice for businesses looking to enhance their biodiesel production capabilities without the significant investment associated with brand-new machinery. The Alfa-Laval P2 (50 SS) plate and frame heat exchanger included in the module further supports efficient thermal management during processing, contributing to overall energy savings and improved yield. This biodiesel module is designed to meet the rigorous demands of industrial applications, making it a valuable asset for any biodiesel production facility.

Key Features:

High-Speed Performance, Durable Construction, Advanced Control System, Efficient Thermal Management, Compact Design