Description:

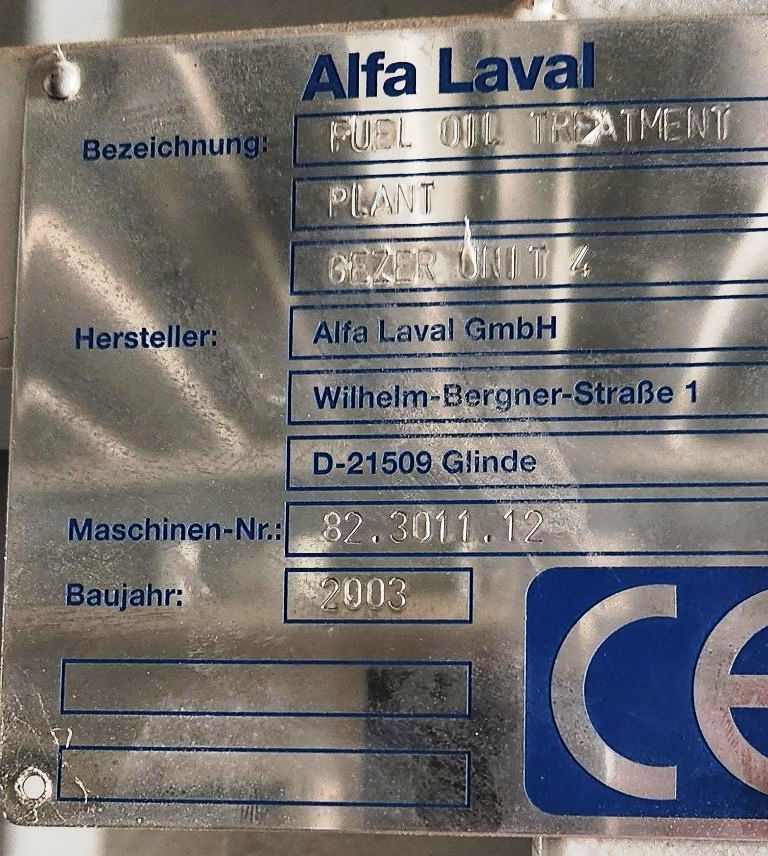

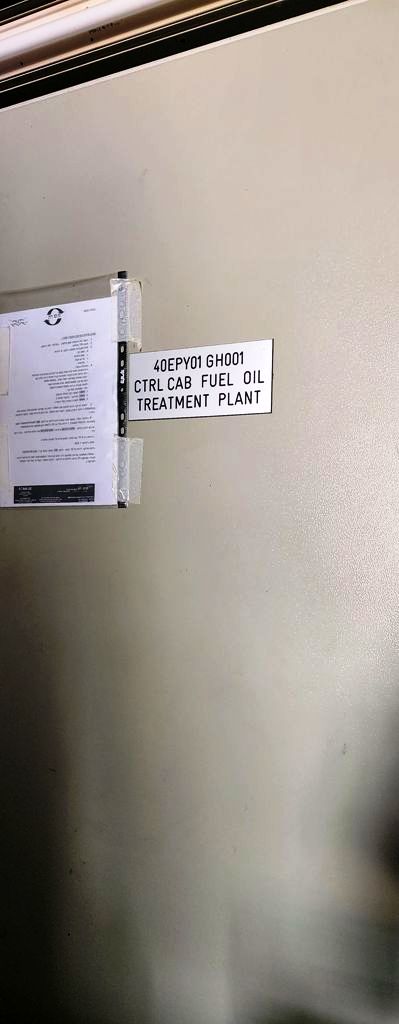

Each container includes (4) GT 50 separators rated @ 50,000 LPH (220 GPM) on distillate #2 gas turbine fuel oil. Optiflow inlet, optimized disc stack, 30 KW motor 400/3/50/1450 RPM, pumps, piping/connections, tools and control panels. 2003 vintage. Never used. Original cost was EUR2.5M each. Located in Middle East.

The (2) Alfa-Laval fuel oil treatment plants are engineered for high-efficiency separation of fuel oil, specifically designed to handle distillate #2 gas turbine fuel oil with a remarkable throughput of 50,000 liters per hour (220 gallons per minute). Each unit is equipped with four GT 50 separators, which utilize an optimized disc stack and Optiflow inlet technology to ensure superior performance and reliability. The 30 kW motor operates at 400 volts, 3-phase, 50 Hz, and 1450 RPM, providing the necessary power to maintain consistent operation under varying load conditions. This robust design not only enhances the separation process but also minimizes energy consumption, making it an ideal choice for facilities looking to optimize their fuel treatment processes while maintaining environmental compliance.

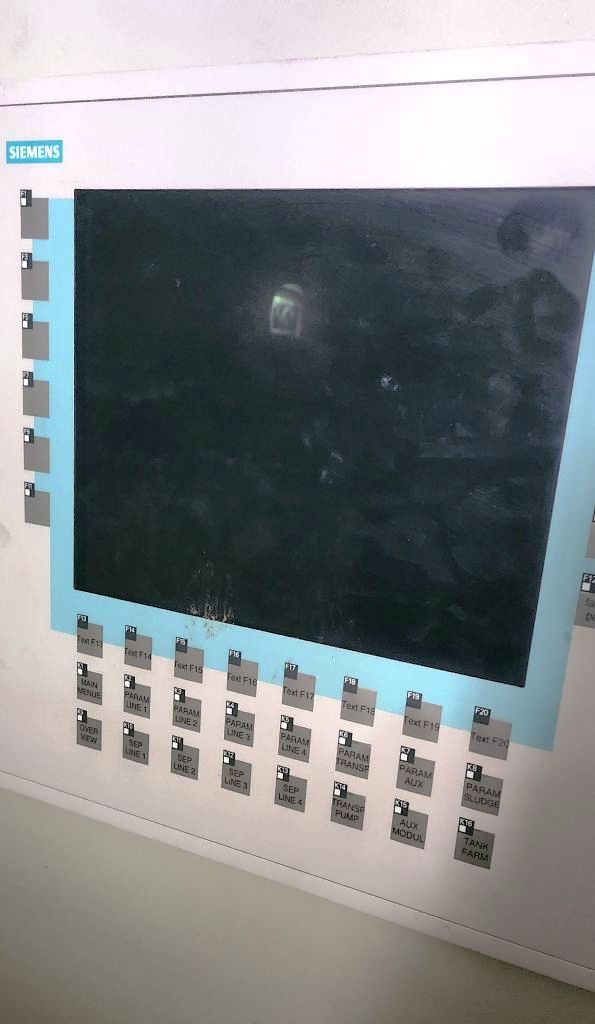

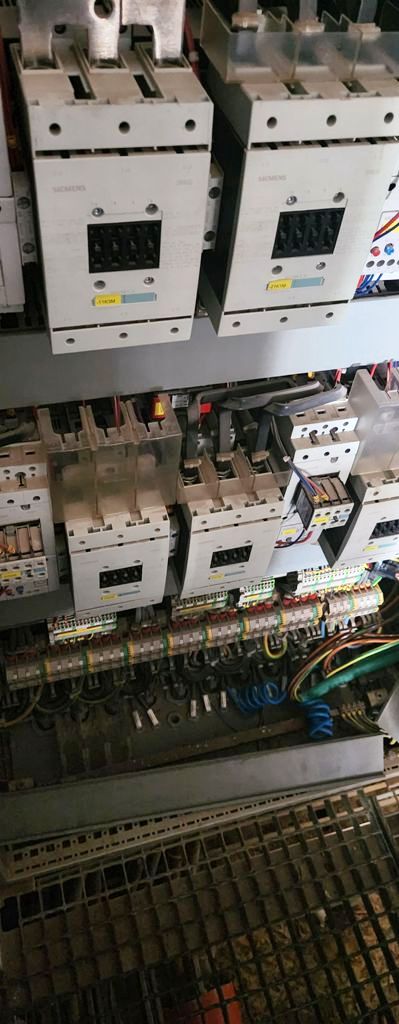

The comprehensive package includes essential components such as pumps, piping, connections, and control panels, ensuring that the plants are ready for immediate installation and operation. The inclusion of tools further simplifies maintenance and troubleshooting, allowing operators to keep the systems running smoothly. Despite being vintage models from 2003, these treatment plants have never been used, representing a significant opportunity for buyers to acquire high-quality industrial equipment at a fraction of the original cost, which was EUR 2.5 million each. Located in the Middle East, these plants can be a strategic asset for companies looking to enhance their fuel oil treatment capabilities without the lead time associated with new equipment procurement.

Key Features:

High-Speed Performance, Durable Construction, Comprehensive Package, Energy Efficient, Optimized Technology