Description:

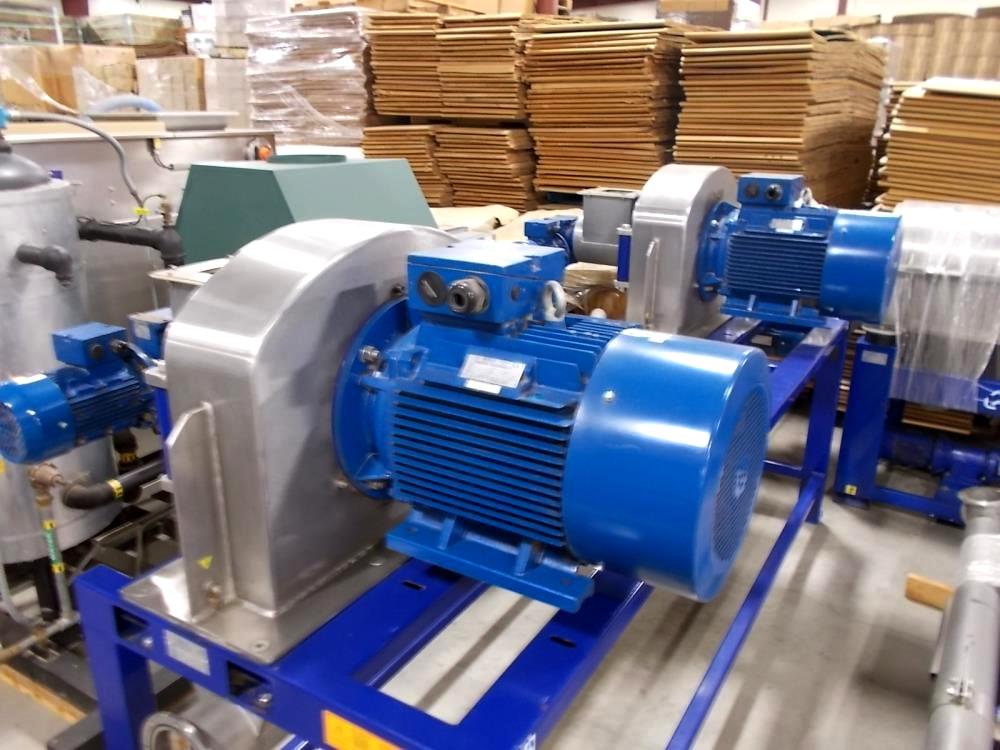

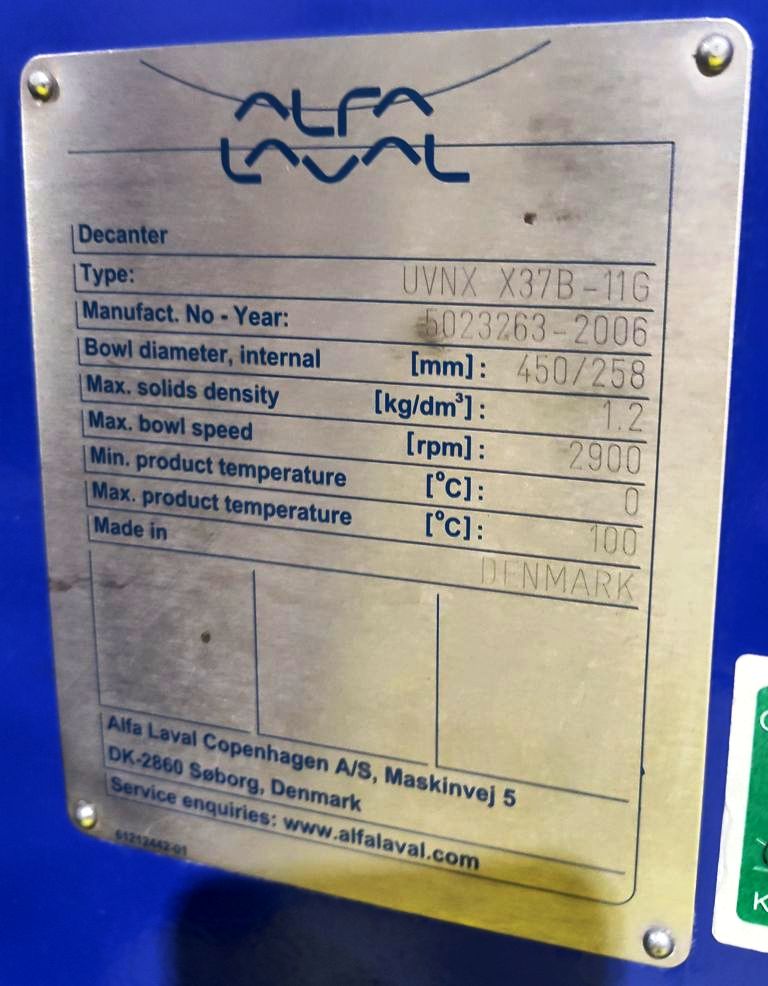

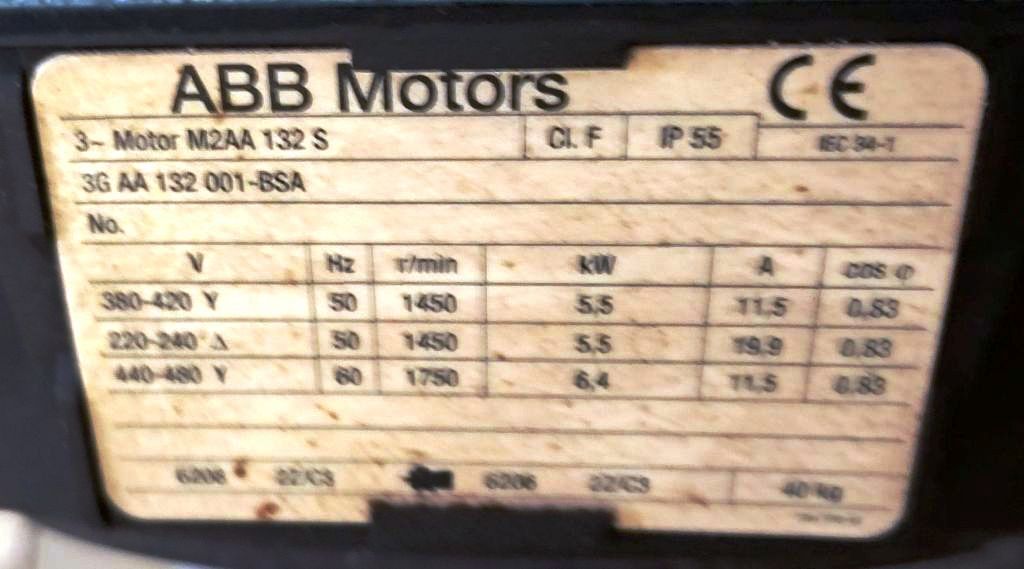

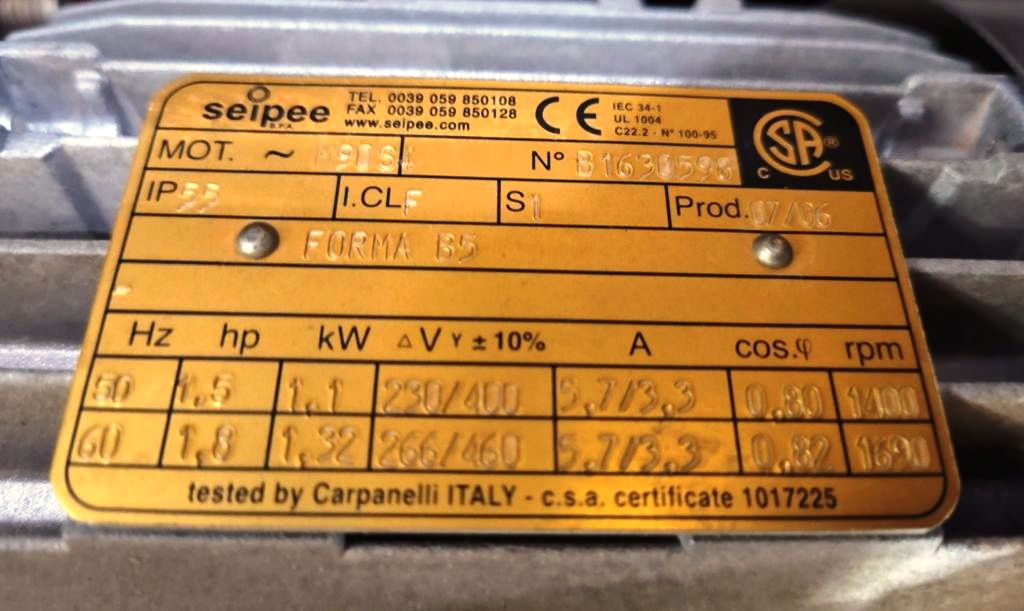

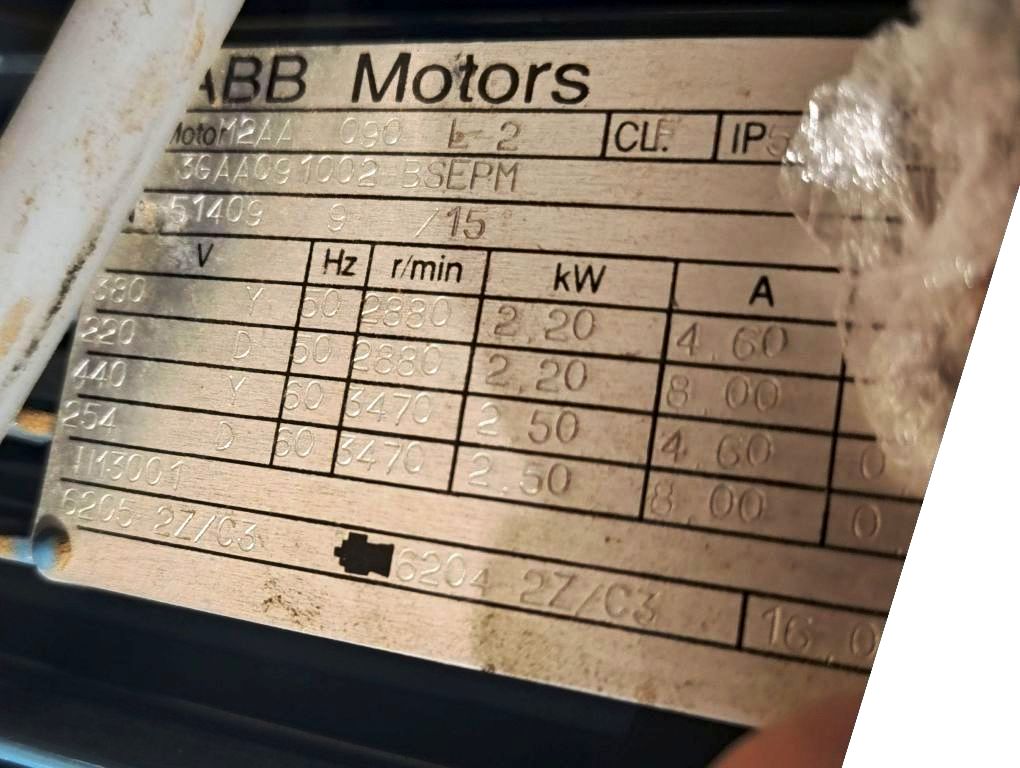

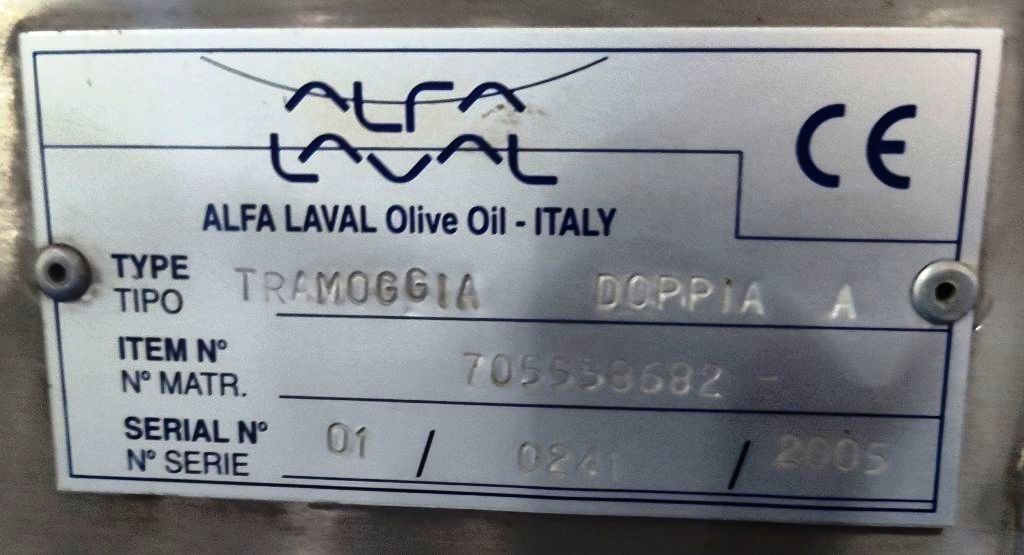

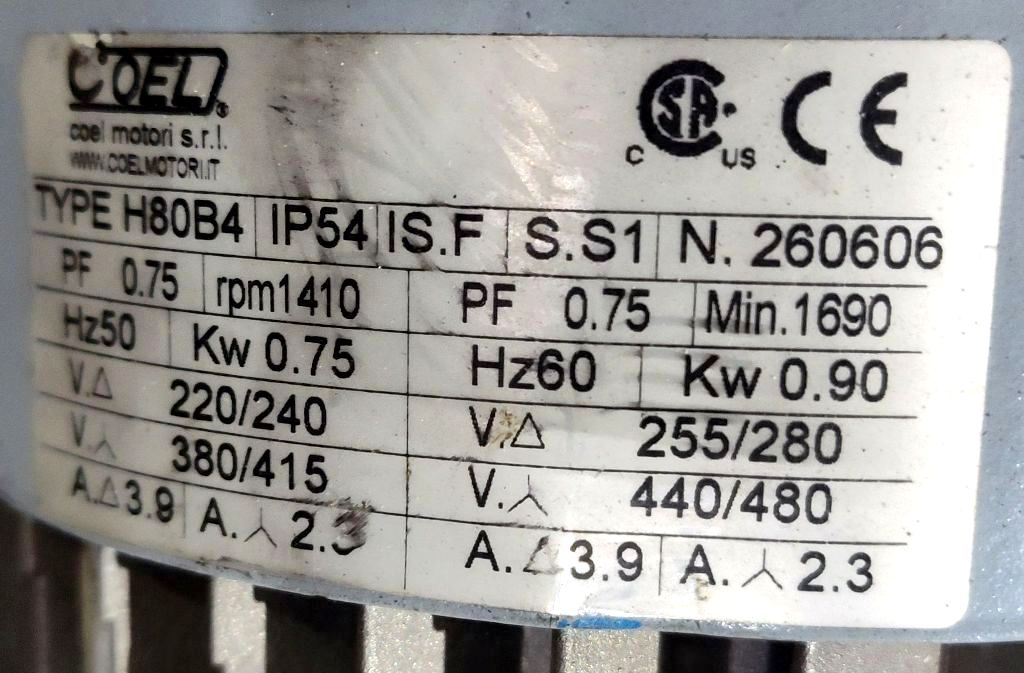

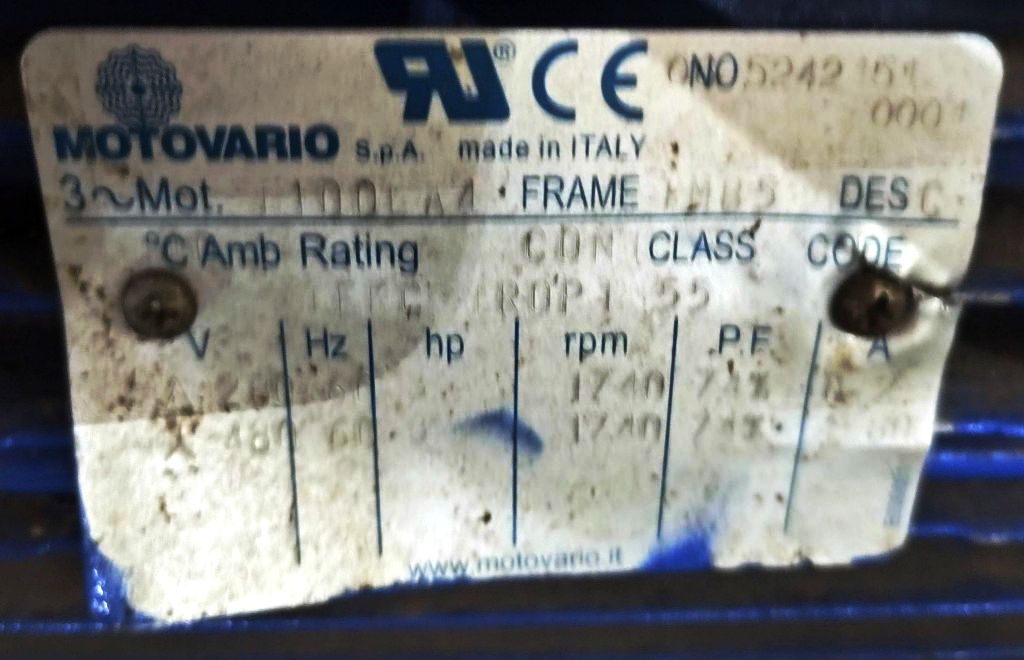

Fully automated plant includes (2) Alfa‑Laval UVPX 507 separators, Alfa‑Laval UVNX 937 decanter centrifuge, (2) hydraulic super washers and destoners with vibrating screens, centrifugal pump, (2) hammer crushers, several screw conveyors, (3) malaxers, (2) depitting machines, Mono feed pumps, 12 x 12 plate and frame heat exchanger, several tanks, motors, piping and controls. 2006 vintage. Excellent condition, stored indoors, only 90 hours of use. New cost: $1.6 M, 15 month delivery.

The Alfa-Laval Complete 8-10 TPH Olive Oil Processing Line is designed for efficiency and high-quality output, making it an ideal choice for olive oil producers looking to enhance their production capabilities. This fully automated plant integrates advanced technology to streamline the olive oil extraction process, ensuring optimal yield and quality. The inclusion of two Alfa-Laval UVPX 507 separators and an Alfa-Laval UVNX 937 decanter centrifuge allows for precise separation of oil from solids and water, resulting in a superior product with minimal impurities. Additionally, the hydraulic super washers and destoners equipped with vibrating screens ensure that the olives are thoroughly cleaned and free from contaminants before processing, which is crucial for maintaining the integrity of the final oil product.

With a robust design, the Alfa-Laval Complete 8-10 TPH Olive Oil Processing Line is built to withstand the rigors of continuous operation. The system features two hammer crushers that efficiently break down olives, facilitating the malaxation process conducted by the three malaxers. This is essential for releasing the oil from the olive paste. The line also includes several screw conveyors for seamless material handling, ensuring that each stage of the process flows smoothly. The 12 x 12 plate and frame heat exchanger is another critical component, allowing for temperature control during oil extraction, which can significantly influence the flavor and quality of the olive oil. Given its excellent condition, with only 90 hours of use and stored indoors, this processing line represents a significant investment opportunity for businesses looking to expand or upgrade their olive oil production capabilities.

Key Features:

High-Speed Performance, Durable Construction, Advanced Automation, Efficient Material Handling, Optimal Temperature Control