Description:

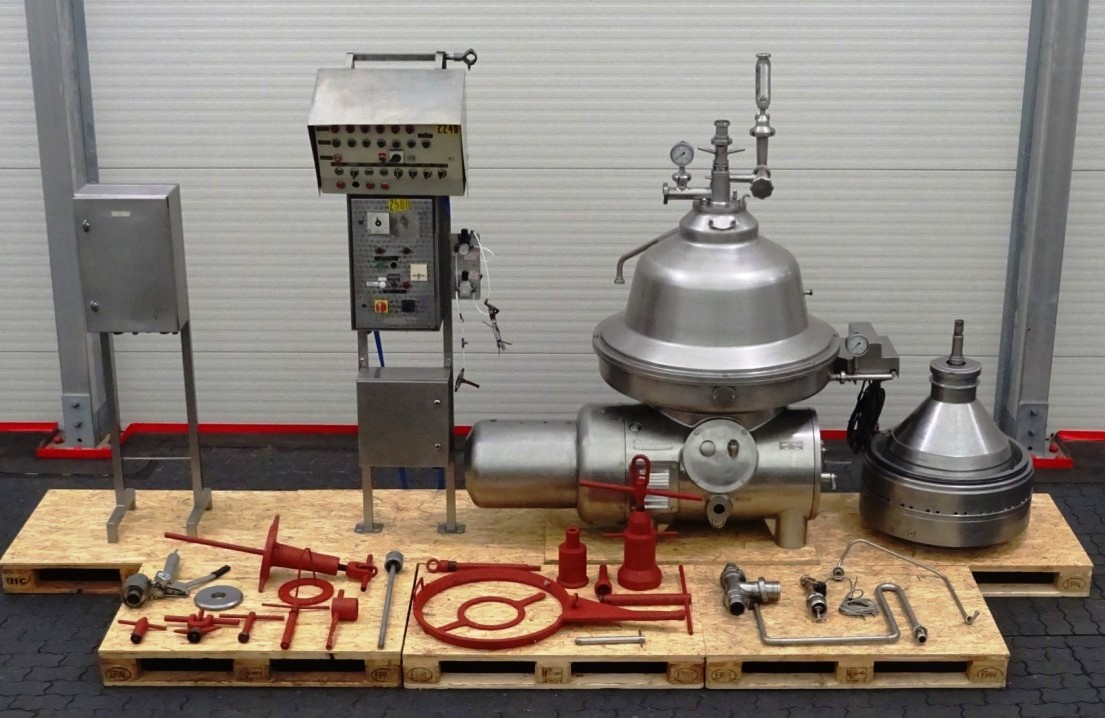

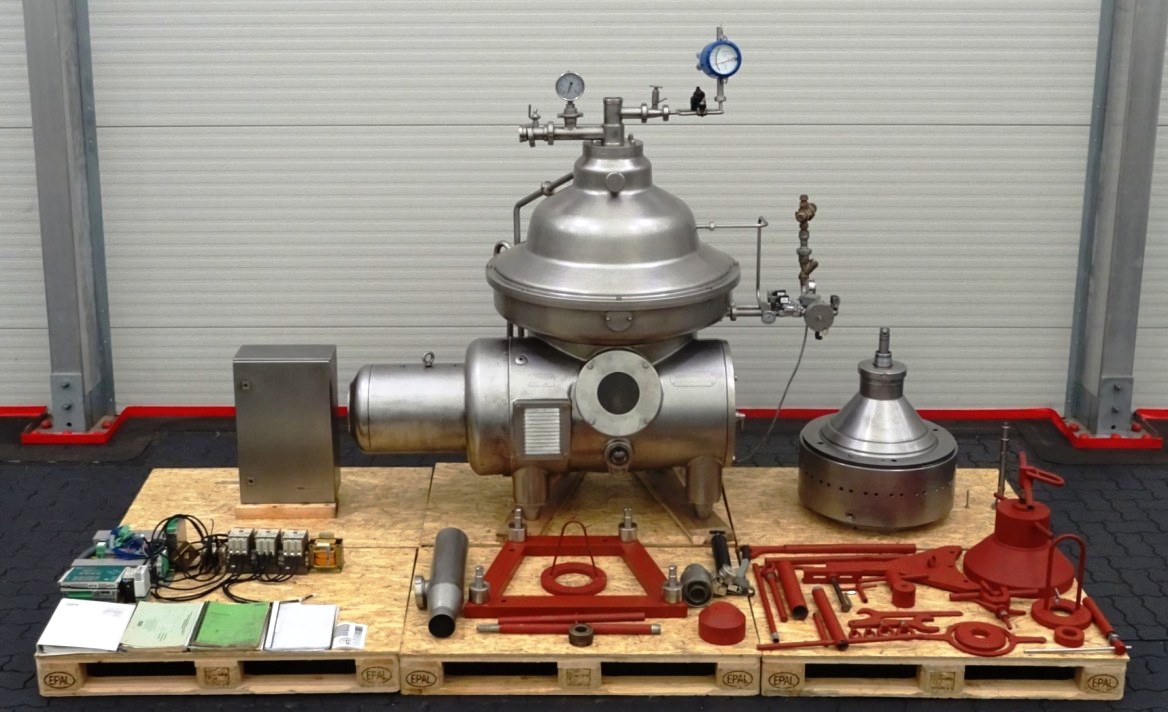

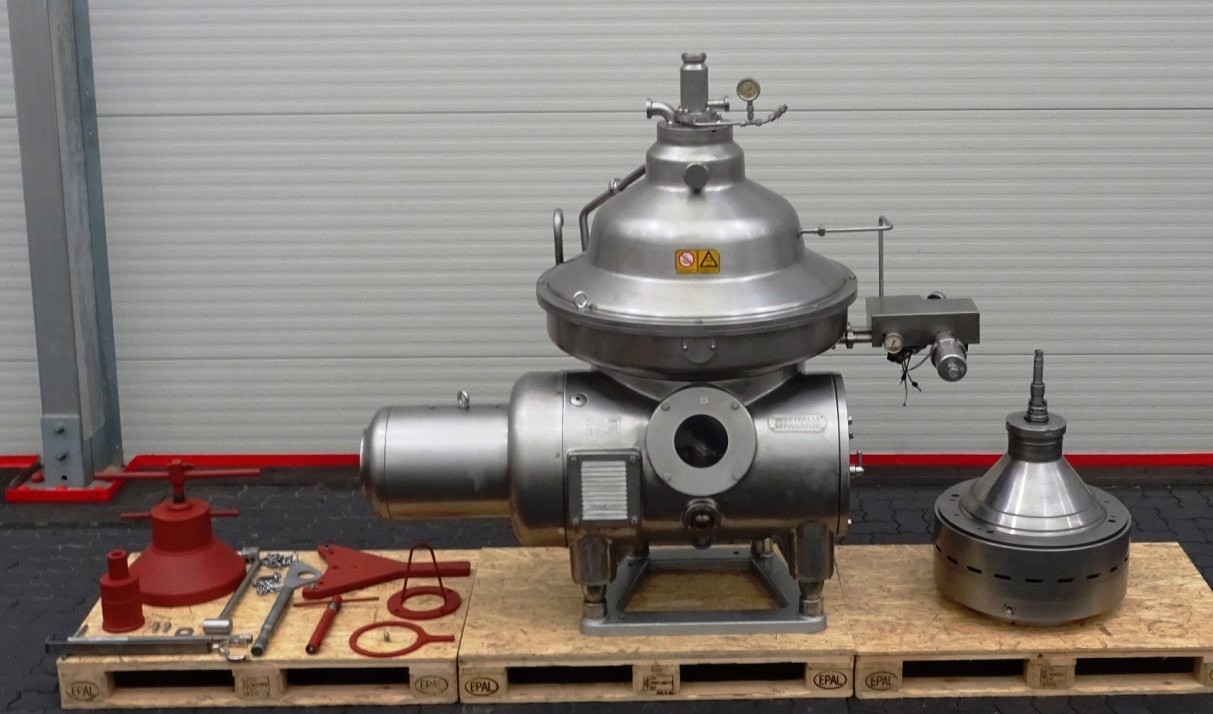

Max bowl speed 4500 RPM, rated @ 15,000 LPH, 50 HP motor 460/3/60/1750 RPM, sludge tank, tools and controls. Excellent condition. Equivalent to MSA 120-01-076.

The Westfalia SAMM 15006 milk separator, 316SS. is engineered for high-efficiency milk processing, making it an essential piece of equipment for dairy operations seeking to enhance their production capabilities. With a maximum bowl speed of 4500 RPM, this separator is designed to effectively separate cream from milk at an impressive rated capacity of 15,000 liters per hour. The robust 50 HP motor operates at 460 volts, 3-phase, 60 Hz, and 1750 RPM, ensuring reliable performance even under demanding conditions. The inclusion of a sludge tank allows for efficient collection and management of by-products, contributing to a cleaner operational environment and minimizing waste. This model is in excellent condition, reflecting its durability and reliability in continuous use, making it a valuable addition to any dairy processing facility.

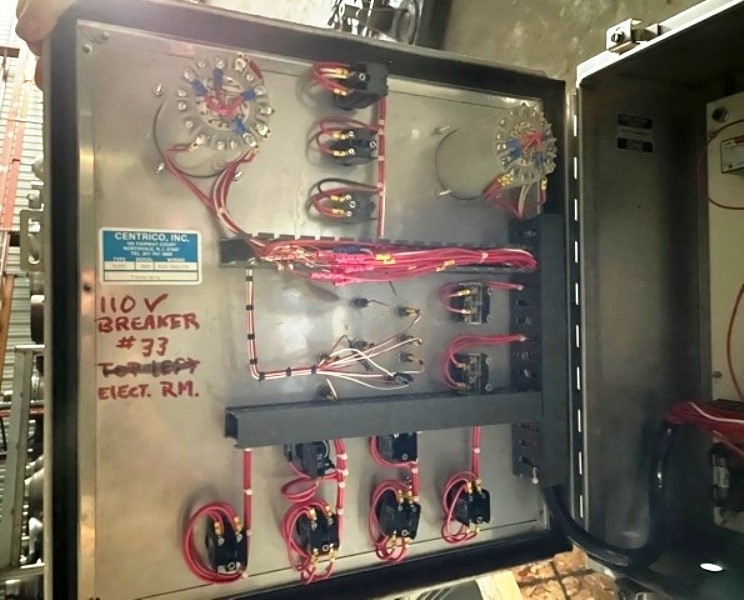

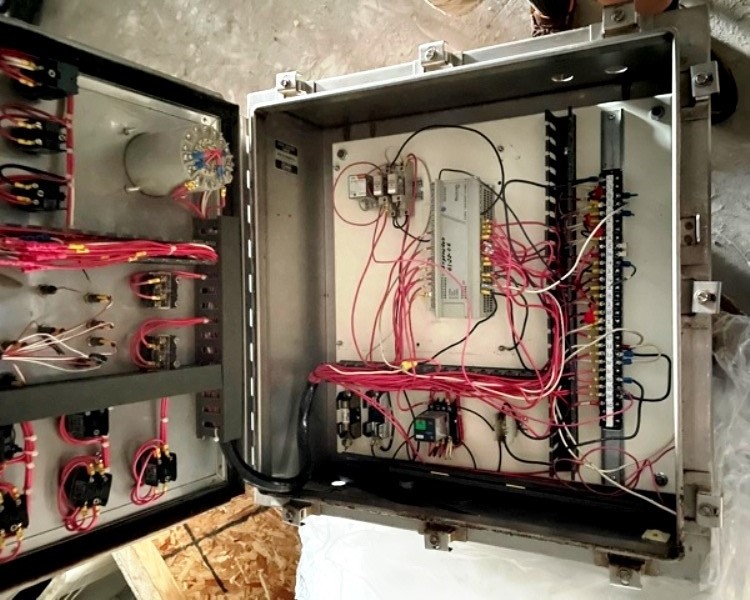

Constructed from high-quality 316 stainless steel, the Westfalia SAMM 15006 milk separator is not only built to withstand the rigors of daily operation but also complies with stringent hygiene standards essential in the food industry. The stainless steel material ensures resistance to corrosion and easy cleaning, which is crucial for maintaining product quality and safety. The separator comes equipped with necessary tools and controls, allowing for straightforward operation and maintenance. Its design prioritizes user-friendliness, making it accessible for operators of varying experience levels. Furthermore, this separator is equivalent to the MSA 120-01-076, indicating its compatibility with existing systems and parts, which can be beneficial for facilities looking to upgrade or replace older equipment without significant modifications.

In summary, the Westfalia SAMM 15006 milk separator, 316SS. stands out as a high-performance solution for dairy processing needs. Its combination of speed, capacity, and construction quality makes it an ideal choice for businesses aiming to optimize their milk separation processes. By investing in this equipment, operators can expect enhanced efficiency, reduced operational costs, and improved product quality, ultimately leading to greater customer satisfaction and profitability.

Key Features:

High-Speed Performance, Durable Construction, Efficient Waste Management, User-Friendly Operation, Hygienic Design