Description:

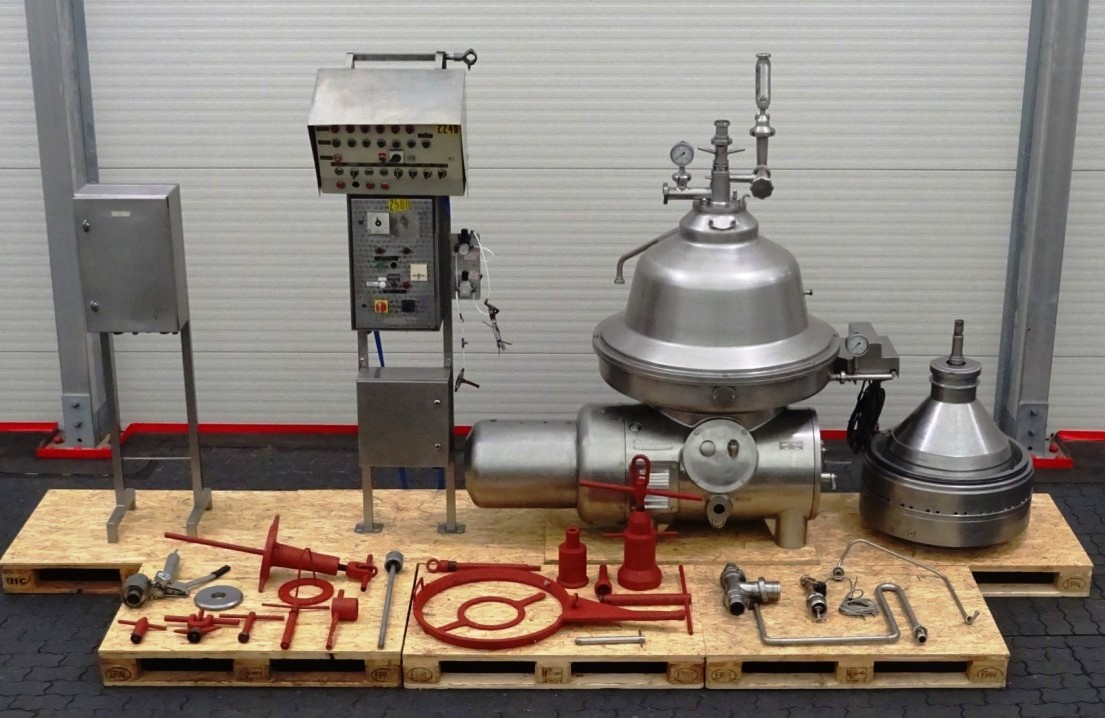

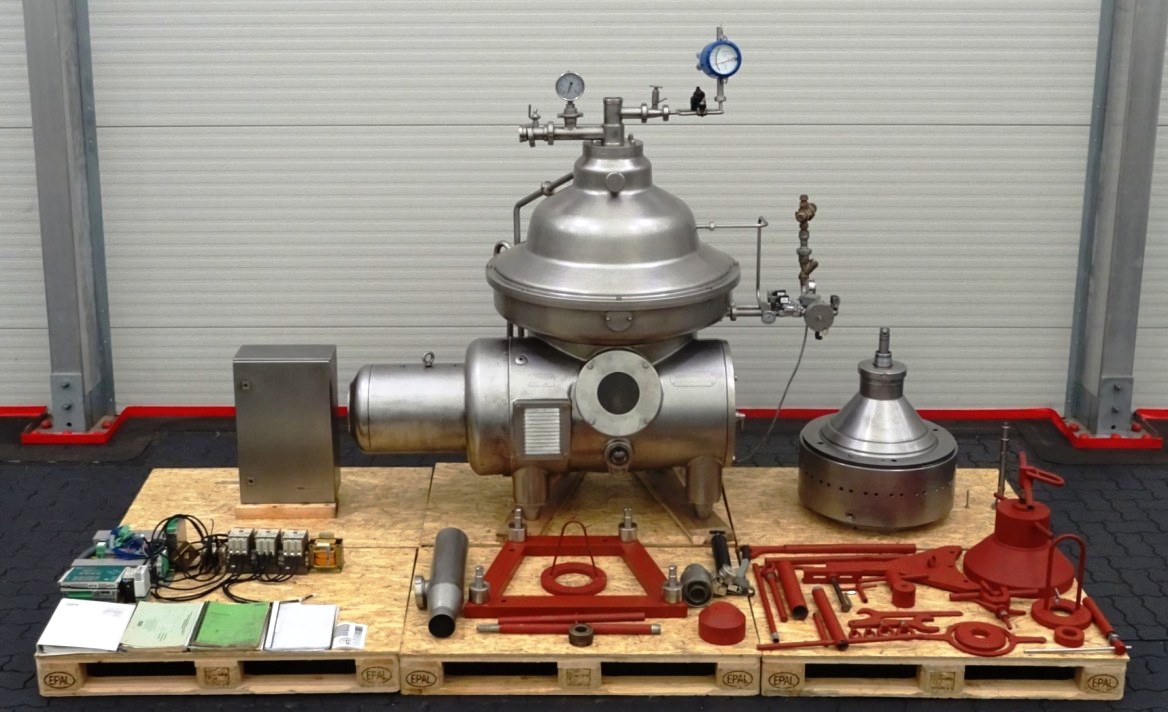

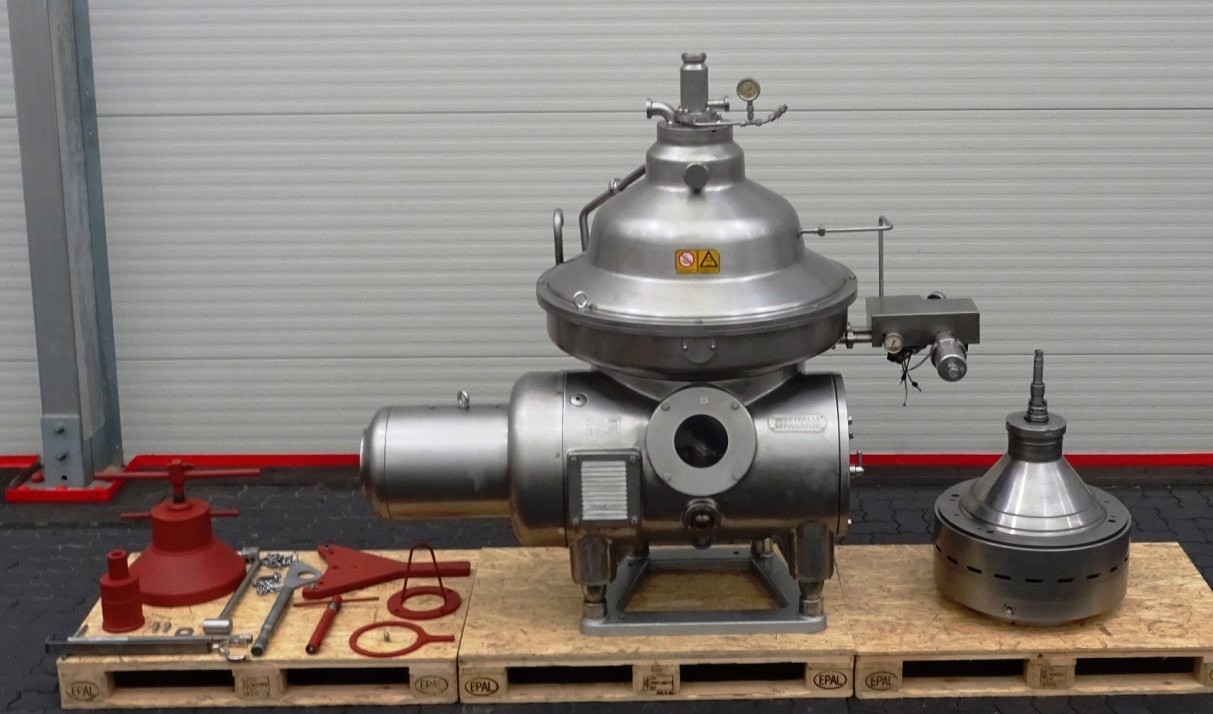

Max bowl speed 4500 RPM, rated @ 15,000 LPH, 37 KW motor 380/3/50/1450 RPM, sludge tank, mixing tank, pumps, gauges, 2 GEA heat exchangers, all piping, tools and ABB control panel. Reconditioned and unused since. EXW Europe.

The Westfalia SAMM 15006 milk separator system, 316SS. is engineered to deliver exceptional performance in the dairy processing industry. With a maximum bowl speed of 4500 RPM and a throughput capacity rated at 15,000 liters per hour, this system is designed to efficiently separate cream from milk, ensuring optimal yield and quality. The robust 37 KW motor operates at 380V/3/50Hz with a speed of 1450 RPM, providing the necessary power to handle large volumes of milk while maintaining consistent operational efficiency. This system is equipped with essential components including a sludge tank and a mixing tank, which facilitate the effective handling of by-products and enhance the overall separation process. Additionally, the inclusion of pumps, gauges, and two GEA heat exchangers ensures that the system operates smoothly and effectively, allowing for precise temperature control and efficient heat transfer during processing.

Constructed from high-quality 316 stainless steel, the Westfalia SAMM 15006 milk separator system is designed for durability and longevity, making it suitable for the rigorous demands of industrial dairy applications. The stainless steel construction not only provides resistance to corrosion and wear but also ensures compliance with hygiene standards, which is critical in food processing environments. The system comes complete with all necessary piping, tools, and an ABB control panel, enabling straightforward installation and integration into existing production lines. The reconditioned status of this equipment means it has been thoroughly inspected and restored to ensure optimal performance, making it a reliable choice for businesses looking to enhance their dairy processing capabilities. With the Westfalia SAMM 15006, you can expect improved efficiency, reduced downtime, and a high return on investment, all while maintaining the quality standards required in the dairy industry.

Key Features:

High-Speed Performance, Durable Construction, Comprehensive System Components, Efficient Heat Exchange, Hygienic Design

Frequently Asked Questions

We're sorry, but this item has been sold.

Please consider the alternatives below.